Low power consumption permanent magnet biased axial magnetic bearing

A technology of axial magnetic bearing and permanent magnet bias, which is applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the problems of large reluctance, large excitation current, and large power consumption of permanent magnets, and achieve reduced copper consumption, Reduce the effect of controlling the power amplifier loss and low iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

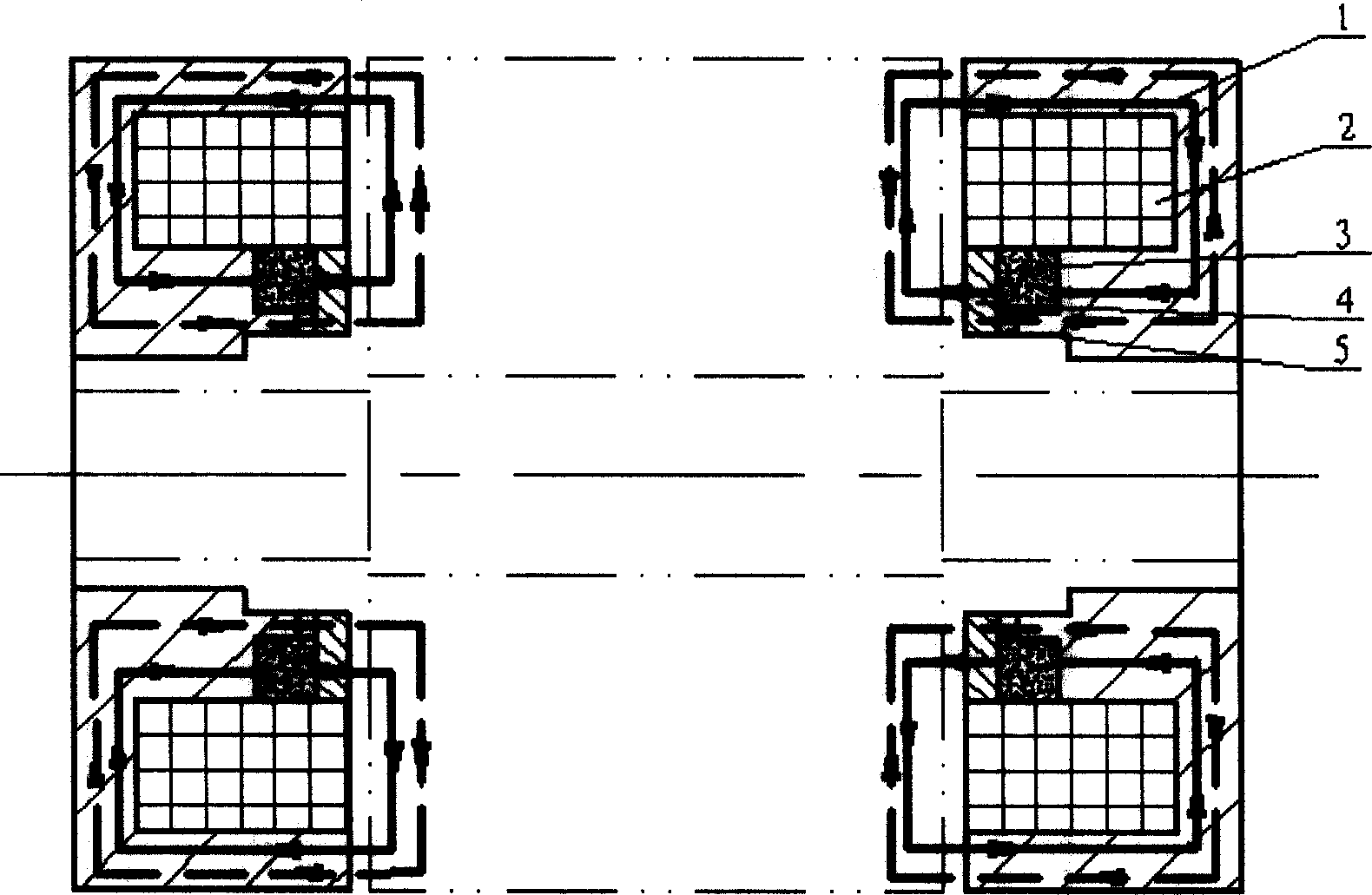

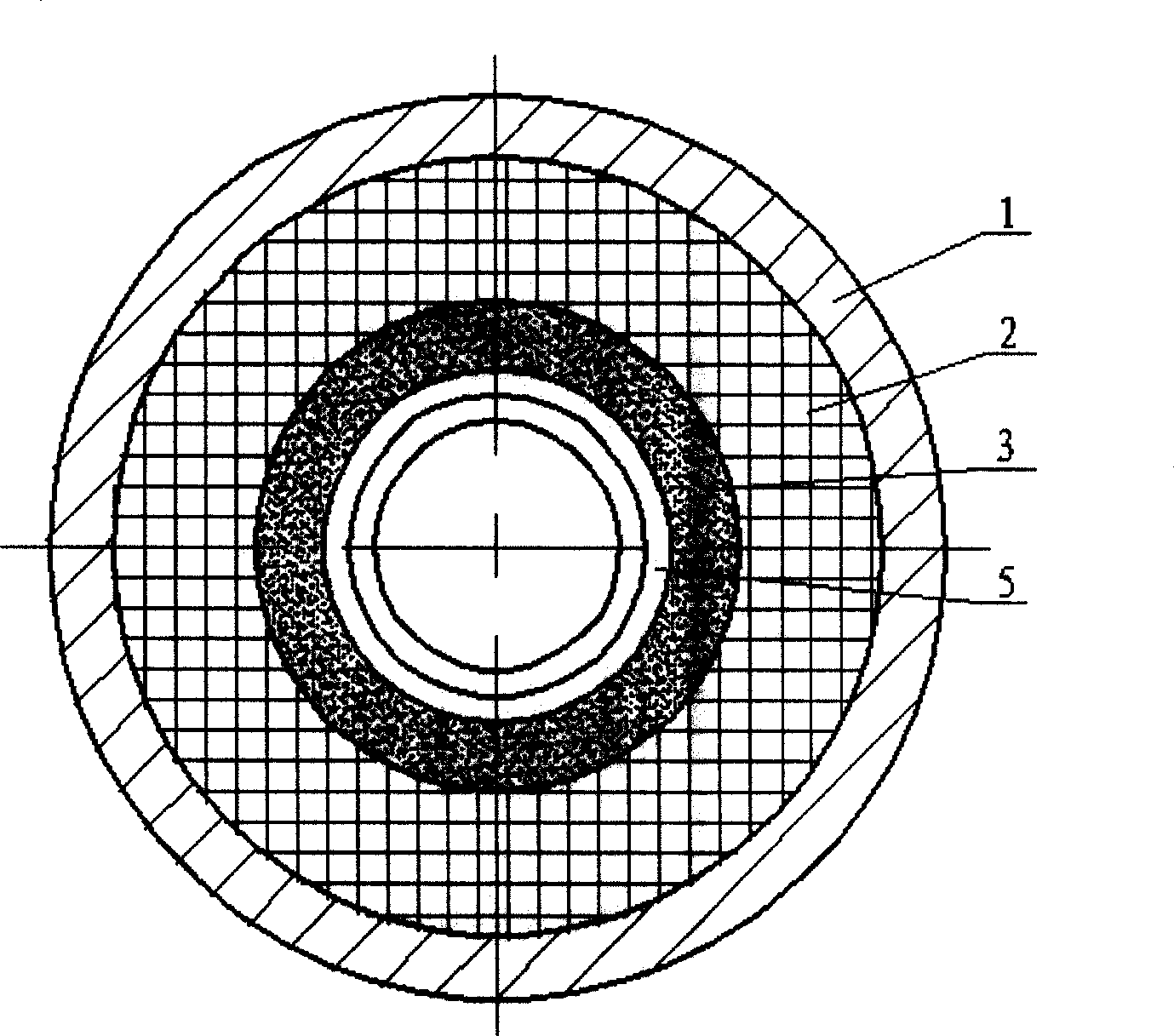

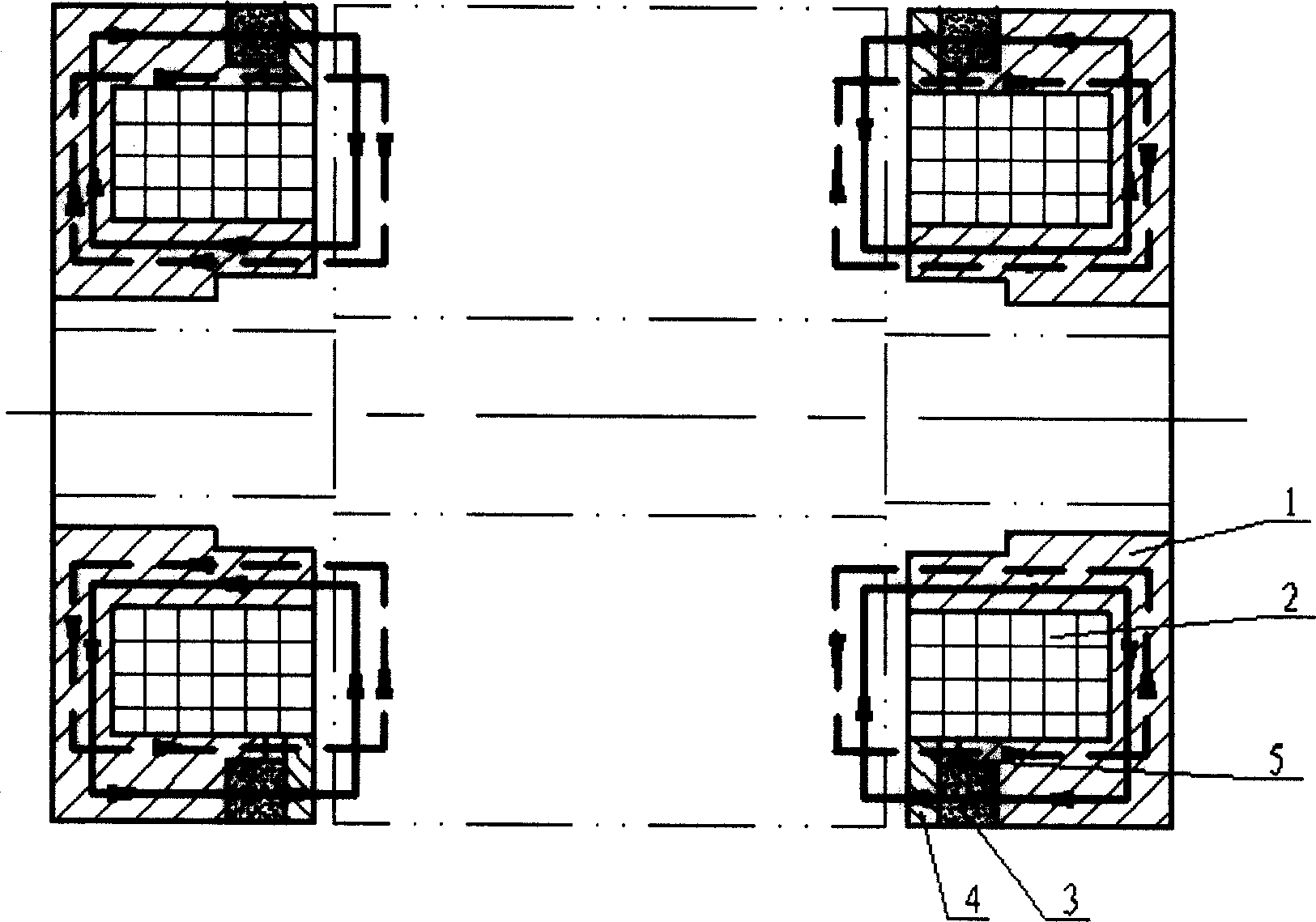

[0013] Such as figure 1 , 2 As shown, it is the low-power permanent magnet bias axial magnetic bearing with inner magnetic steel and outer excitation coil of the present invention, which is the basic form of the present invention. It consists of bearing body 1, excitation coil 2, permanent magnet 3, and magnetic conduction ring 4. Composed of 5 excitation air gaps. The permanent magnet 3 is closely attached to the bearing body 1, and generates magnetic fields of different polarities on the inner and outer air gaps of the magnetic bearing. The excitation coil 2 is wound on the bearing body 1 to generate an excitation magnetic flux. The magnetic conduction ring 4 is closely attached to the On the permanent magnet 3, an excitation air gap 5 is formed between the magnetic conduction ring 4 and the bearing body 1, and the excitation air gap provides a magnetic circuit for the magnetic flux generated by the excitation coil.

[0014] Such as figure 1 , 2 As shown, assuming that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com