Permanent Magnetic Bias Unilateral Axial Magnetic Suspension Bearing

A technology of magnetic suspension bearing and permanent magnet bias, which is applied in the direction of shaft and bearing, bearing, mechanical equipment, etc., can solve the problems of multiple power loss of winding, large volume and weight, and achieves improved cooling capacity, small volume and small magnetic resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

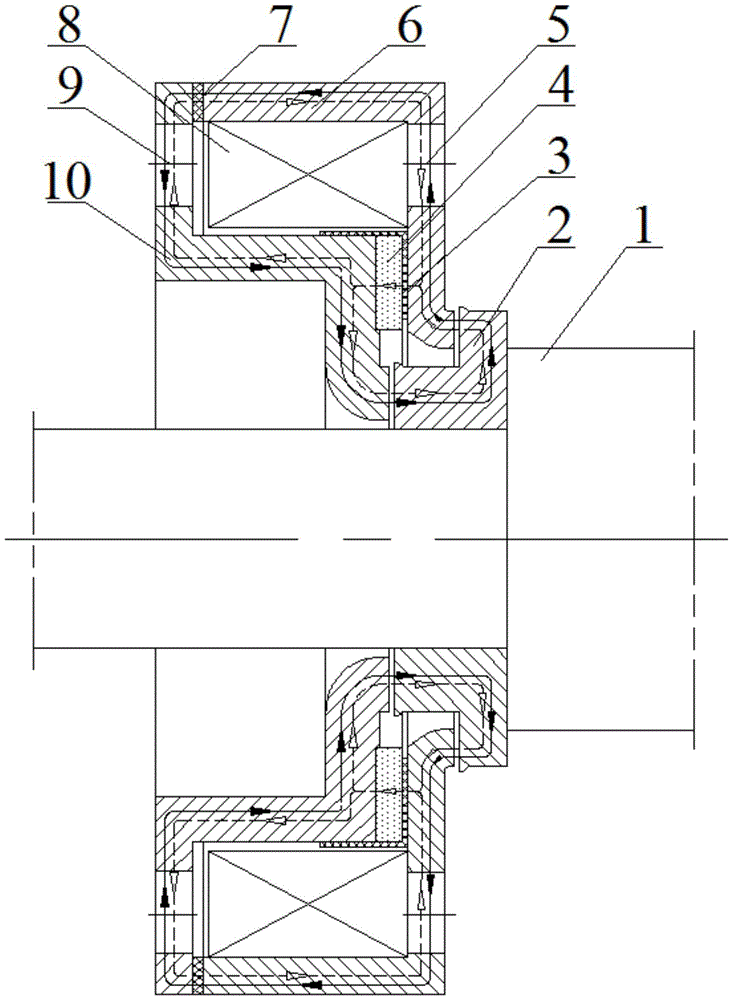

[0021] see figure 1 , the end thrust plate 2 in the figure, the stator inner magnetic pole cooling hole 9, and the stator inner magnetic pole 10 are made of soft magnetic materials; the main shaft 1, the permanent magnet shield 3, and the annular non-magnetic gasket 7 are non-magnetic materials; The annular permanent magnet 4 is a rare earth permanent magnet material or a ferrite permanent magnet material. The large end surface of the end thrust disc 2 is installed close to the step of the main shaft 1; the annular permanent magnet 4 is installed on the cylindrical end surface of the inner magnetic pole 10 of the stator, the permanent magnet shield 3 is installed on the cylindrical end surface and the side surface of the inner magnetic pole 10 of the stator, and the annular permanent magnet 4 Between and in contact with the inner magnetic pole 10 of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com