Clearer roller holding device for drafting arrangements in spinning groups

A drafting device and holding device technology, which is applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of less installation and disassembly costs, and achieve simple installation and disassembly, quick installation and disassembly, and simple structure form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be described in more detail on the basis of an embodiment shown in the figures.

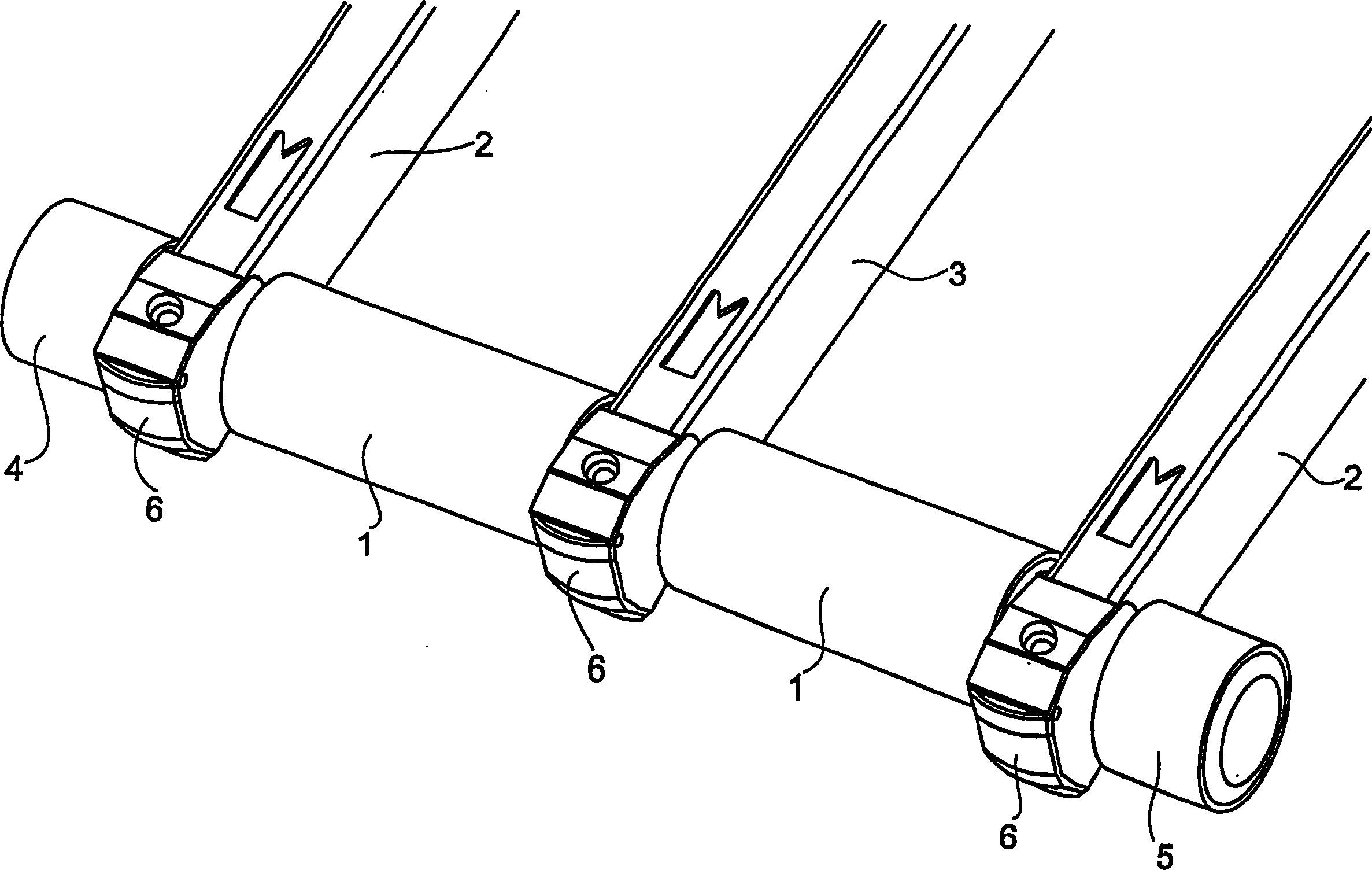

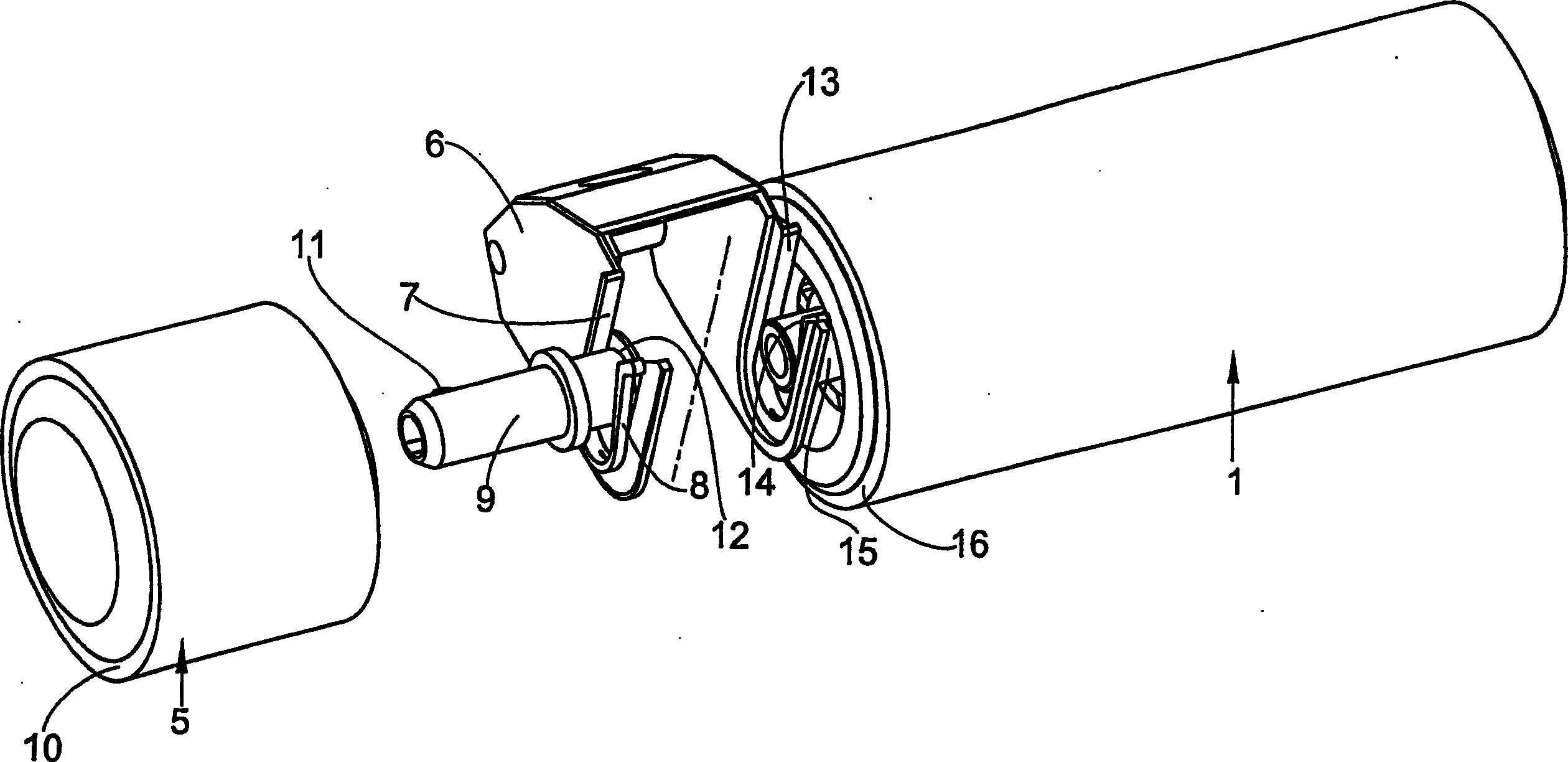

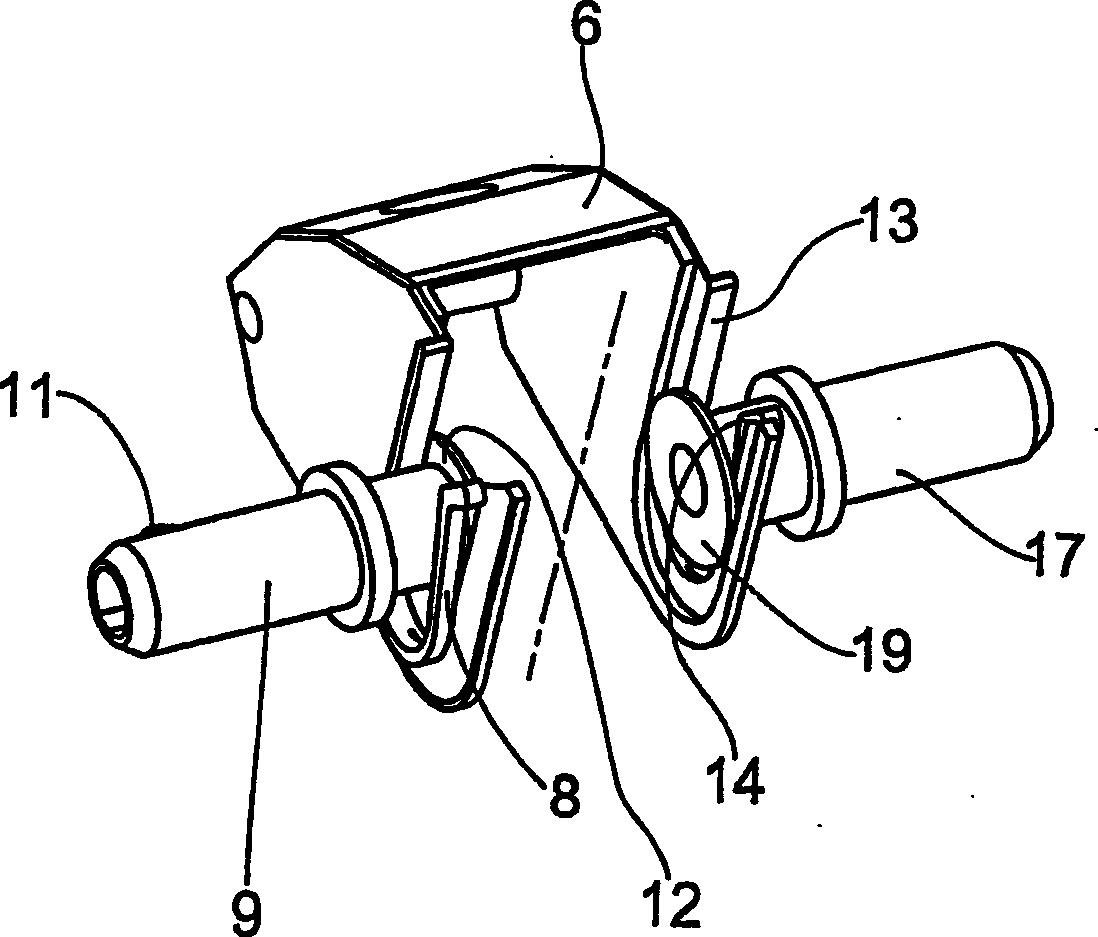

[0020] figure 1 Illustrated is part of a drafting unit having two cleaning rollers 1 each fitted between two upper roller bearing weight arms 2, 3 and positioned on each two of the preceding pair of drafting rollers and two other cleaning rollers 4, 5 on the upper rollers of the outer front pair of drafting rollers beside the outer upper roller bearing weight arm 2. The cleaning roller 1 cooperates with the upper roller of every two tracks, while the cleaning rollers 4, 5 only cooperate with the upper roller of each track during the spinning operation. All pairs of drafting rollers and their arrangement are not shown for reasons of simplicity. The upper roller supports the weighted arms 2, 3 with a bearing element 6, and the cleaning rollers 1, 4, 5 are arranged laterally of the bearing element 6, respectively. The other bearing elements for the cleaning roller and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com