Turbo charger with means on the shaft for axially securing of said shaft if the compressor wheel bursts

一种涡轮增压器、压缩机转子的技术,应用在用于弹性流体的泵送装置的部件、燃气轮机装置、安全装置等方向,能够解决脱落、费时、加固昂贵等问题,达到防止影响、使用简单、价格低廉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

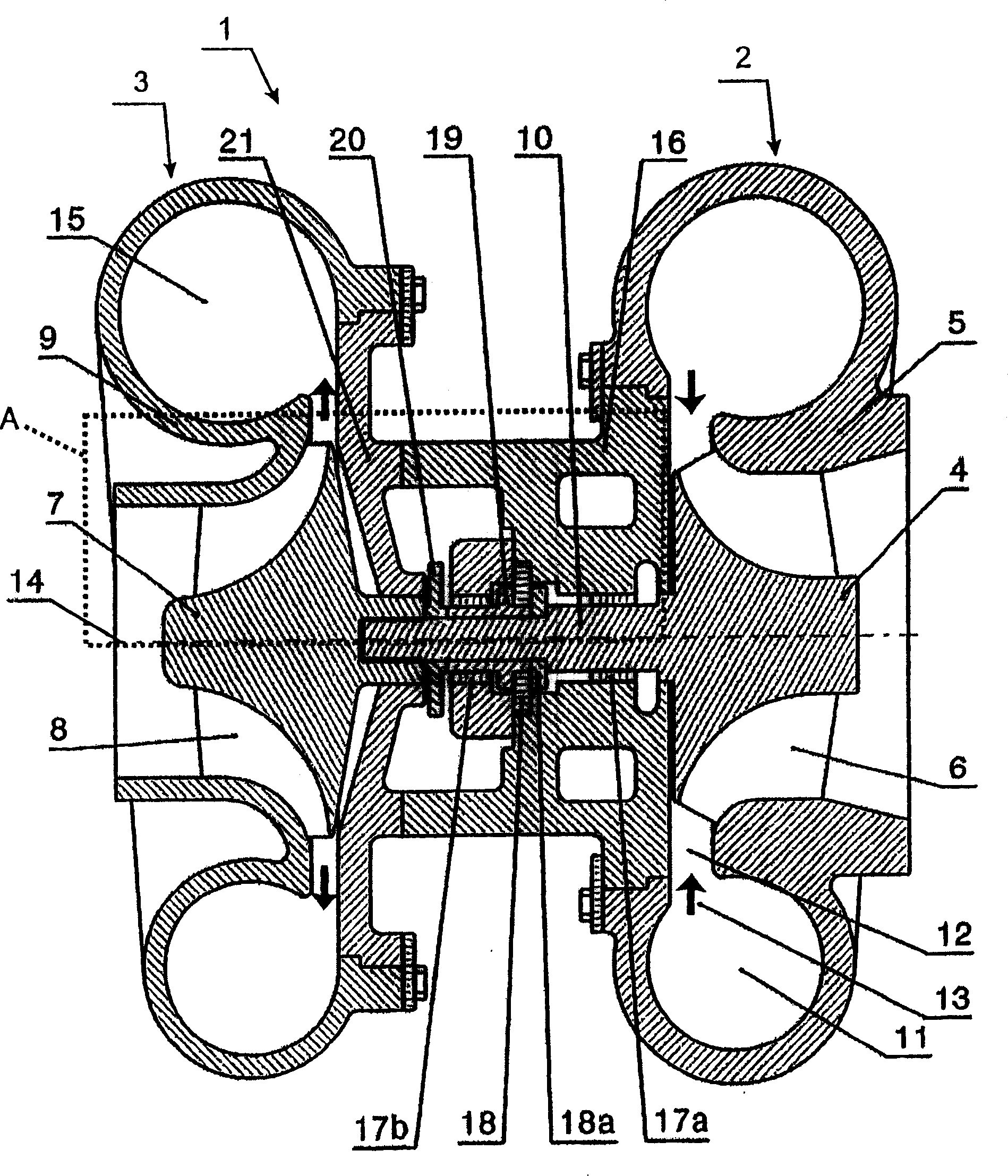

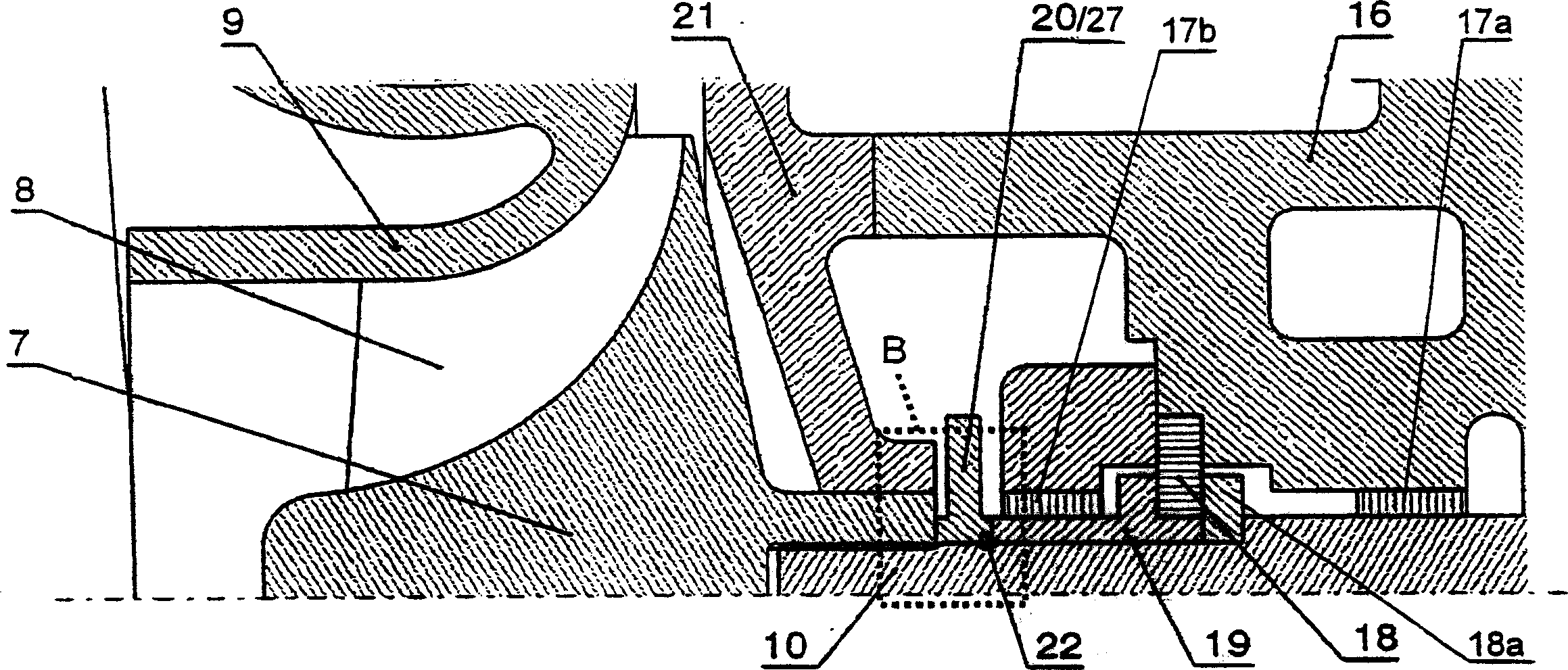

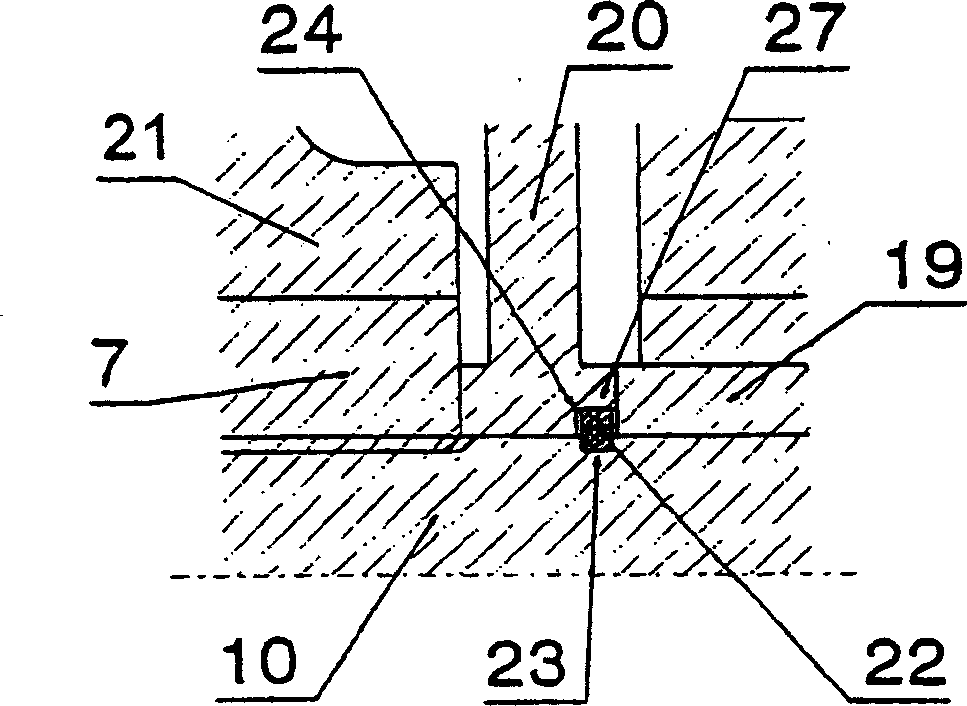

[0015] figure 1 A turbocharger 1 is shown schematically in longitudinal section, comprising a turbine 2 and a compressor 3 . The turbine 2 essentially comprises a turbine 4 with turbine blades 6 and a turbine housing 5 surrounding the turbine 4 . The compressor 3 comprises a compressor rotor 7 with compressor blades 8 and a compressor housing 9 surrounding the compressor rotor 7 . The turbine wheel 4 and the compressor rotor 7 are connected to one another via a shaft 10 , which is supported in a bearing housing by means of various bearing elements. In the exemplary embodiment shown here, the turbine 2 and the compressor 3 are designed as radial turbines and compressors. The turbine 4 is driven by the exhaust gases supplied to the turbine 4 via channels 11 , 12 in a known manner by an internal combustion engine (not shown). The exhaust gas decompressed and cooled by the decompression is discharged via an exhaust gas channel not further shown. Due to the rotational movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com