Ribbed reinforced concrete prefabricated structural board

A technology of reinforced concrete and prefabricated components, which is applied in the direction of building components, floor slabs, building structures, etc., and can solve problems such as complex procedures, time-consuming and labor-intensive production of prefabricated component panels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

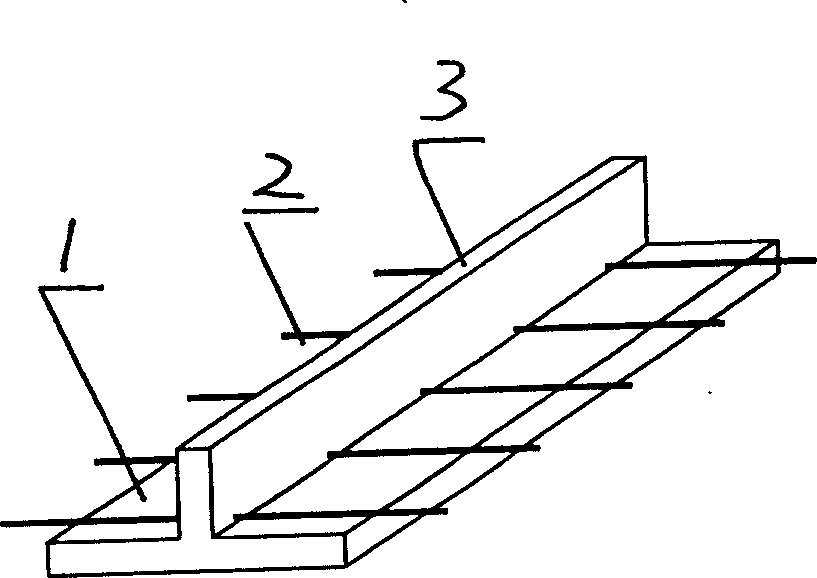

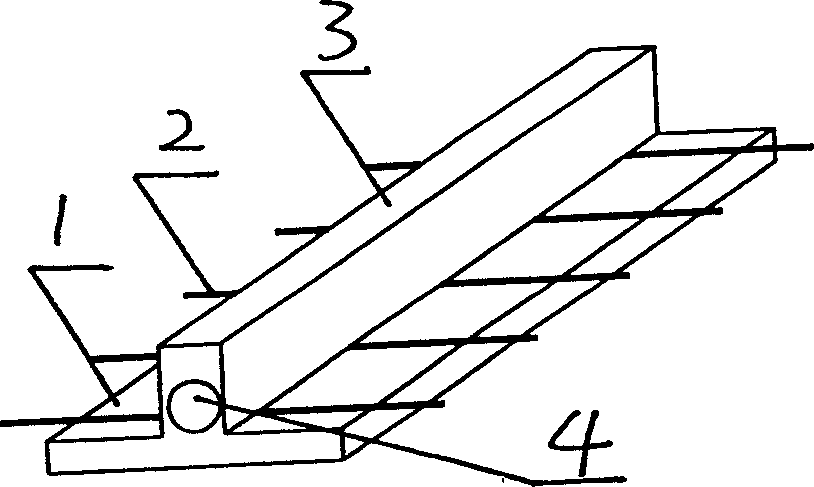

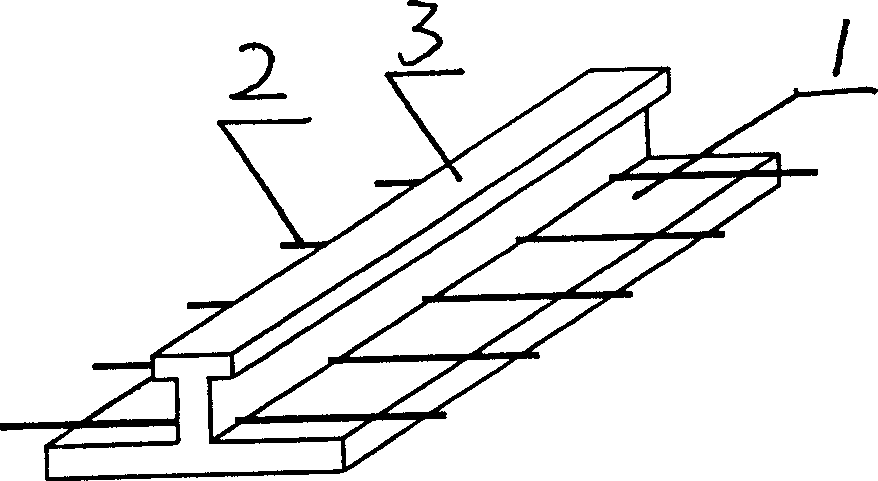

[0017] refer to figure 1 —— Figure 10 , the ribbed reinforced concrete prefabricated component panel includes a reinforced concrete panel body 1 and a longitudinal rib 3, and the two sides of the reinforced concrete longitudinal rib 3 or the panel body 1 are provided with connecting reinforcement bars 2, and the connecting reinforcement bars 2 are used for making the prefabricated component panel When pre-embedded in the longitudinal rib 3 or the plate body 1, the angle between the upper plane of the reinforced concrete plate body 1 and the bottom plane is α≤45 degrees, and the upper plane of the plate body 1 forms an inclined plane to facilitate the installation of connecting steel bars on both sides of the plate body 1 2. It can also improve the bending resistance of the plate body 1 . One or more through holes 4 can be opened on the longitudinal rib 3 .

[0018] refer to Figure 11 When assembling the floor slab, the prefabricated component slab body 1 is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com