Straight cylindrical shaft and inside rail type internal combustion engine

An internal combustion engine, straight cylinder technology, applied in mechanical equipment, machines/engines, etc., can solve problems such as limiting working capacity, and achieve the effects of reducing transmission energy consumption, reducing wear, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

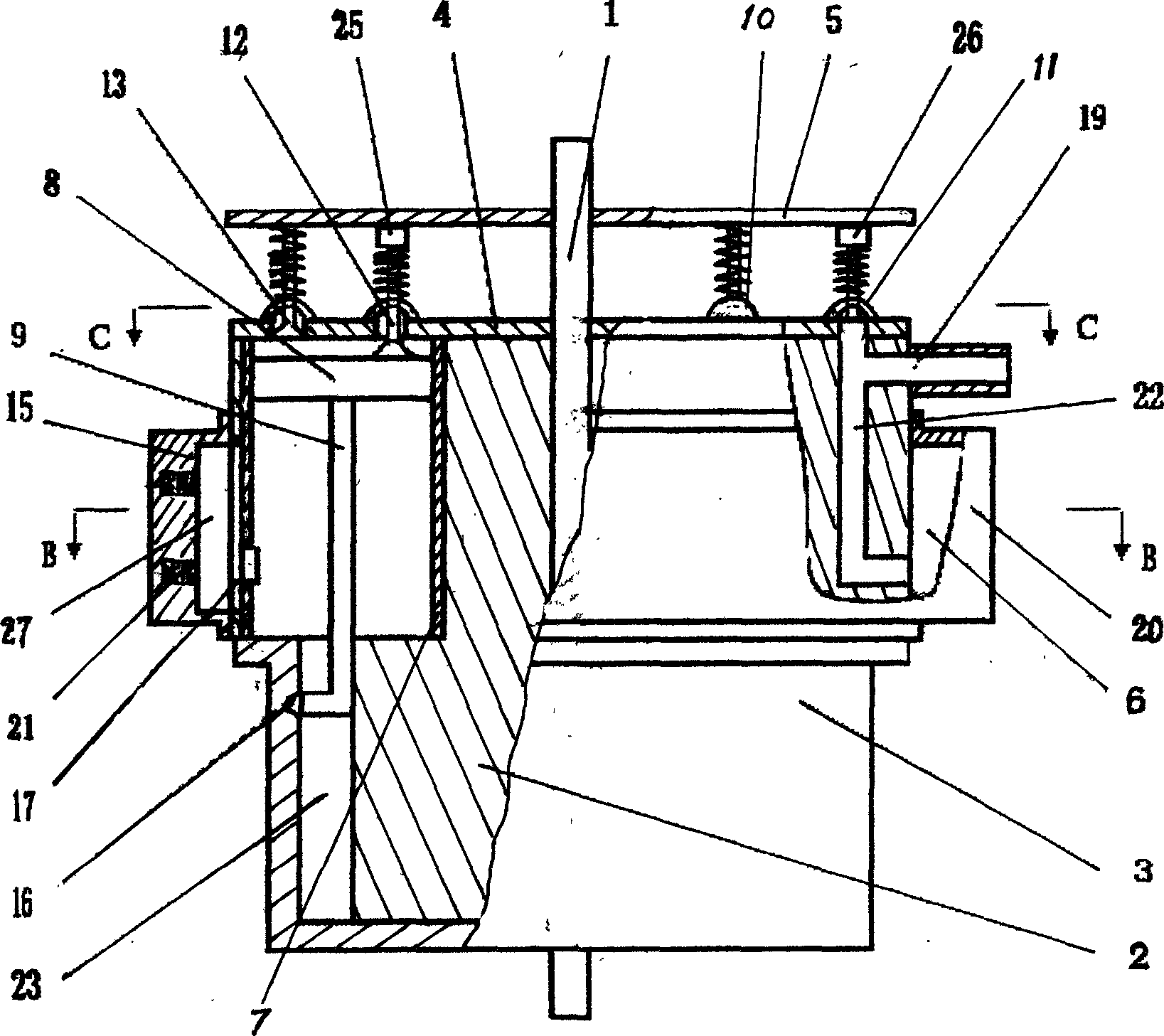

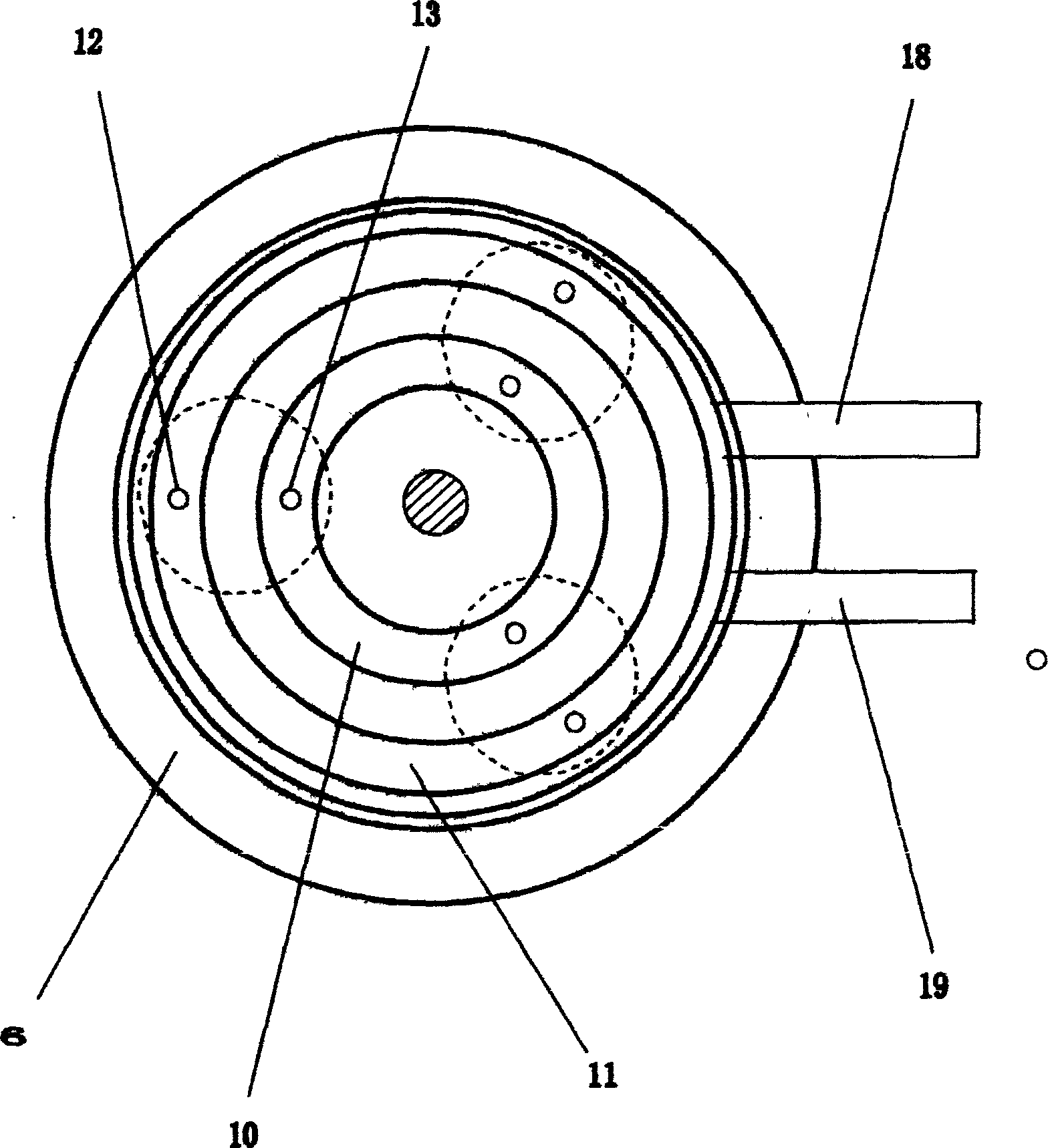

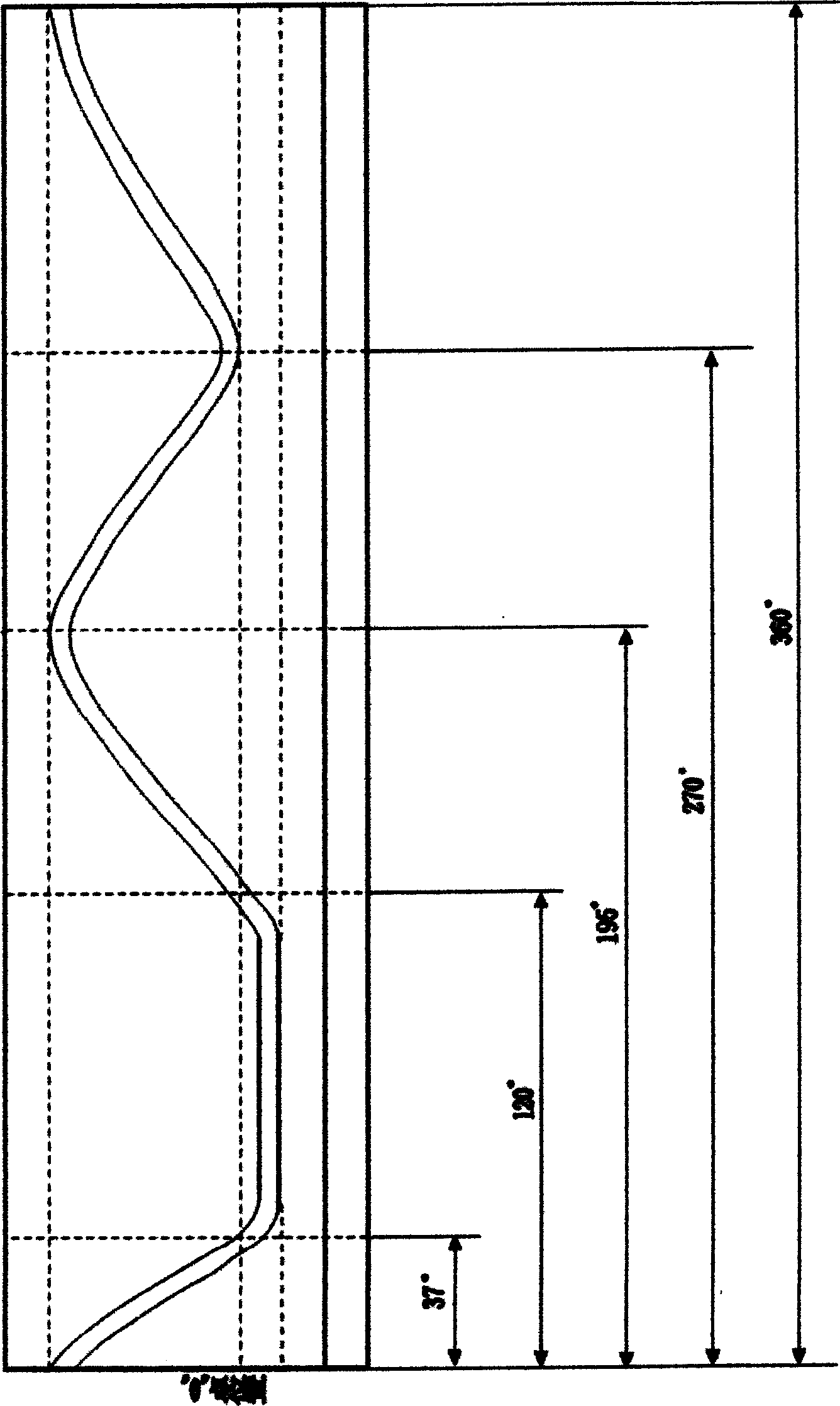

[0013] The present invention takes a three-cylinder four-stroke straight-barrel internal-rail internal combustion engine as an example. The included angle of the four strokes to rotate the central axis is 360°, wherein the power stroke is 120°, the compression stroke is 90°, and the suction and exhaust strokes are each 75°. , the piston stroke distance in each stroke is: the piston stroke distance in the power and exhaust stroke is more than the piston stroke distance in the exhaust and compression stroke by one piston thickness.

[0014] Such as figure 1 , image 3 As shown, the track curve of the groove 16 on the inner wall of the straight cylinder shaft 3 is: the expansion force of the fuel in the power stroke makes the piston rod 9 move vertically downward, and the turning head of the piston rod 9 transmits the force to the groove 16 to make the straight cylinder When the shaft 3 rotates, when the piston 8 reaches the tongue 14 in the communication hole 17 of the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com