Intelligent design method and device for gear material selection and heat treatment process

A technology of intelligent design and reasoning method, applied in the direction of reasoning method, electrical digital data processing, special data processing application, etc., can solve the problems of low design efficiency, unseen patent application, repetitive labor and waste of resources for consulting manuals, etc. The effect of reducing enterprise cost, ensuring generalization accuracy, and shortening design time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

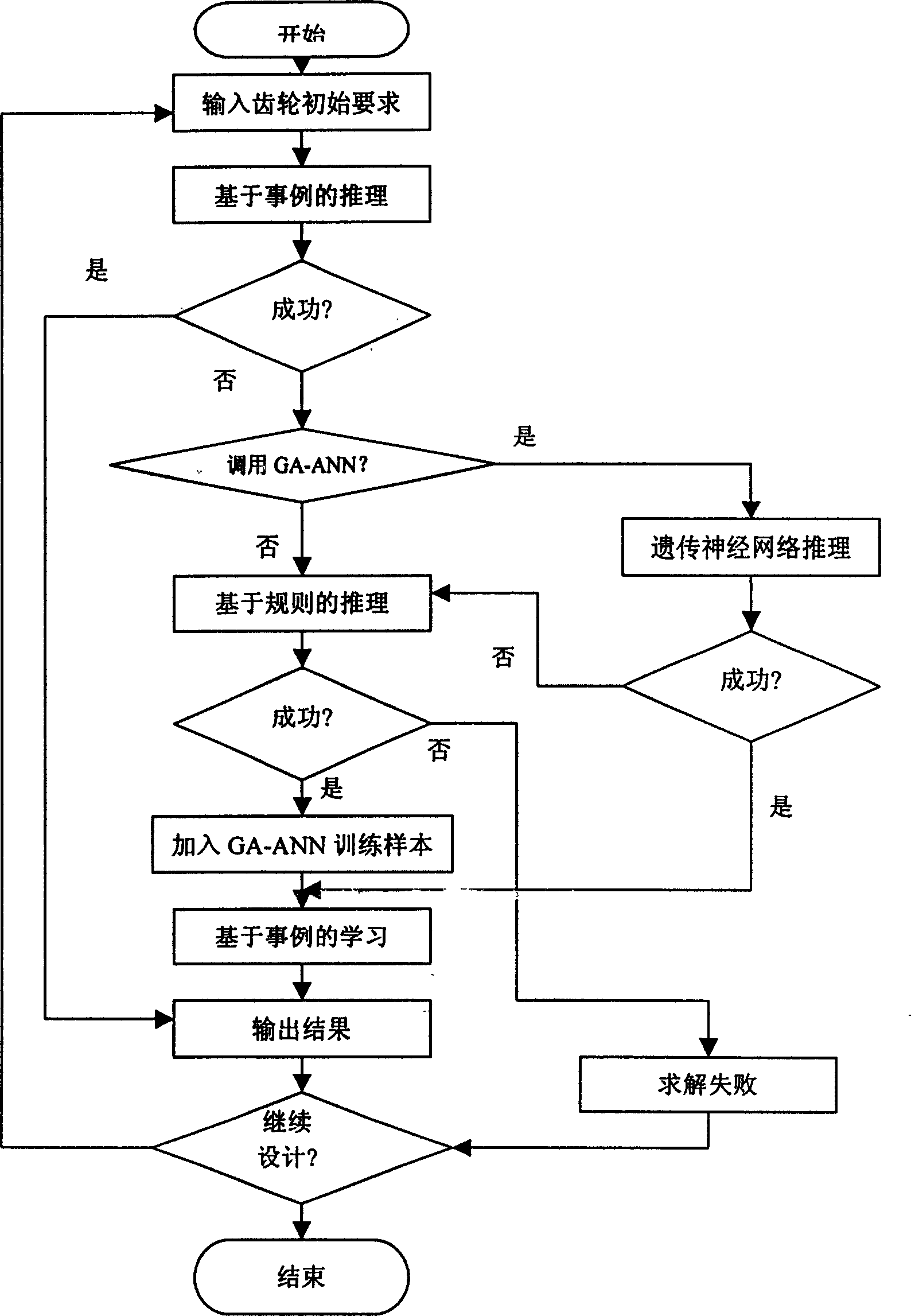

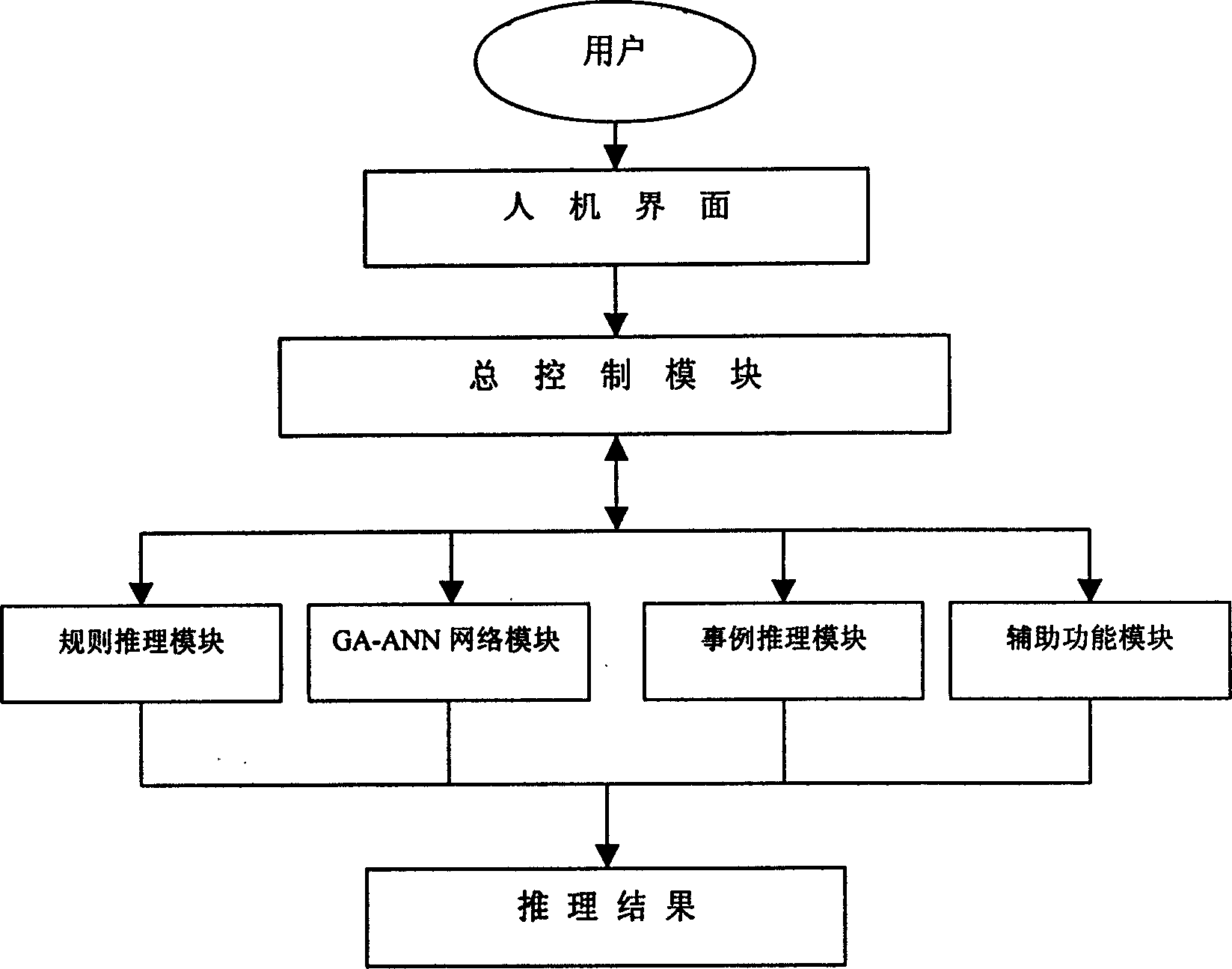

[0025] When the system is carrying out the overall structure practice and integrated model design, it fully considers the actual process of gear material selection and heat treatment process design by experts and engineers and technicians, and tries to simulate the design process of the human brain in the operation process of the system. The reasoning method adopts the combination of case-based, rule-based and genetic neural network. After inputting the initial requirements of the gear, the reasoning of the case is carried out. If it is unsuccessful, it can choose to call the genetic neural network reasoning or rule-based reasoning, and finally get the output result.

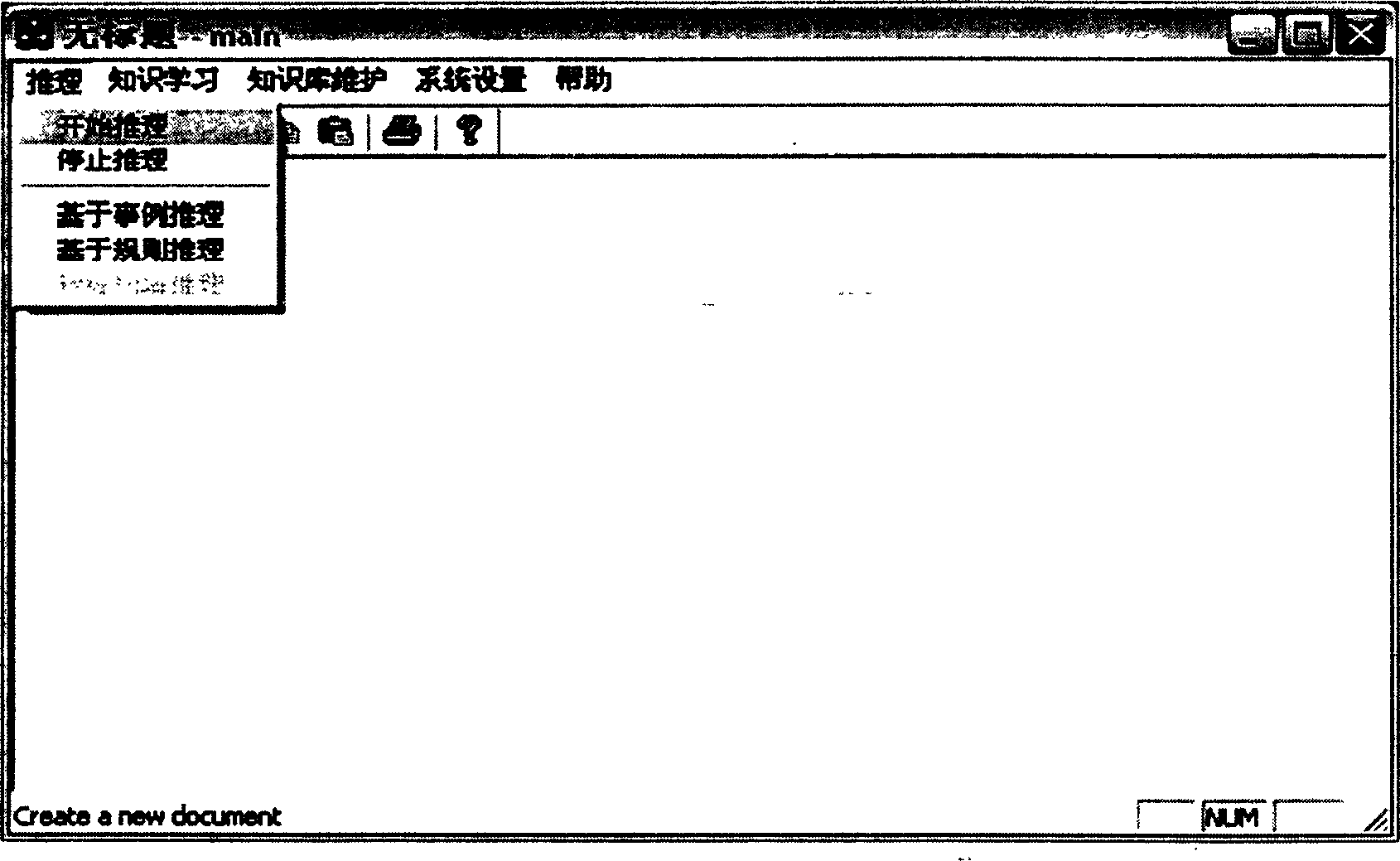

[0026] Combined with Figure 1 and Figure 2, the material selection of gears and the implementation of the heat treatment process expert system are explained in detail. Taking the third category of nitriding gears as an example, the gear requirements to be requested: high-speed wire rolling mill reducer gears, whi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap