Modeling method for residual oil catalytic cracking reaction mechanism model

A catalytic cracking and reaction mechanism technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of not considering the composition and properties of raw materials, unreported application research, and limited application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Below in conjunction with accompanying drawing and by embodiment the present invention will be further described:

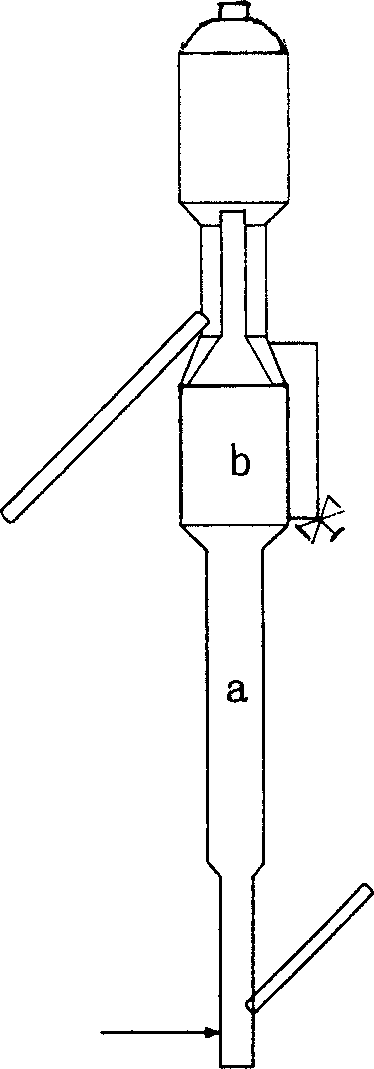

[0079] The validity of the model is verified by using the actual production historical data of a catalytic cracking unit for maximizing the production of isoparaffin residual oil in a certain petroleum refining company. The riser reactor is divided into two reaction zones a and b, such as figure 1 shown.

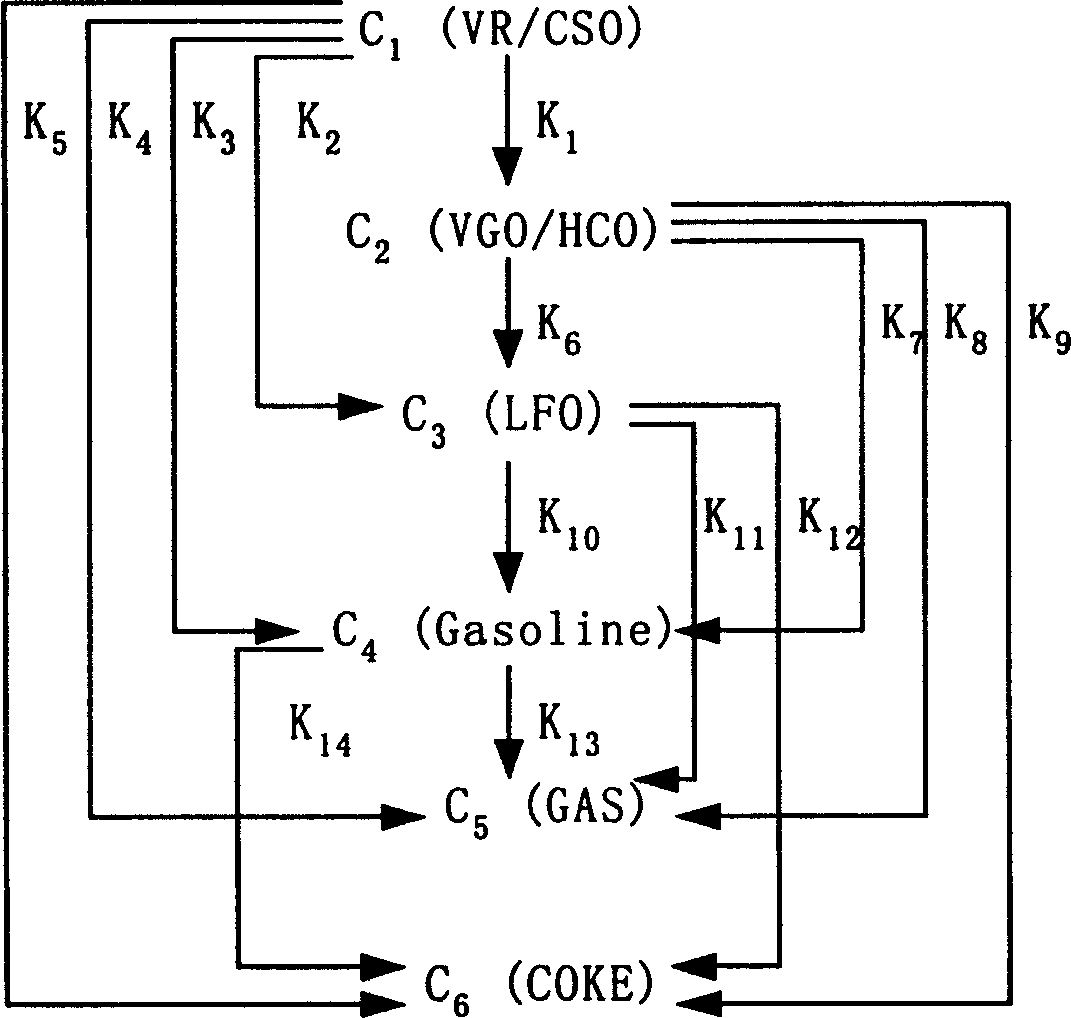

[0080] The reaction system is divided into residue-reducing slurry C according to the requirements of the present invention 1 (VR / CSO), wax oil back to refining oil C 2 (VGO / HCO), Diesel C 3 (LFO), petrol C 4 (Gasoline), liquefied gas dry gas C 5 (GAS) and coke C 6 (COKE) and other 6 aggregates, and establish a series-parallel reaction network for cracking reactions between each aggregate, and the rate constants of the chemical reactions in each step are marked on the graph, as shown in figure 2 shown.

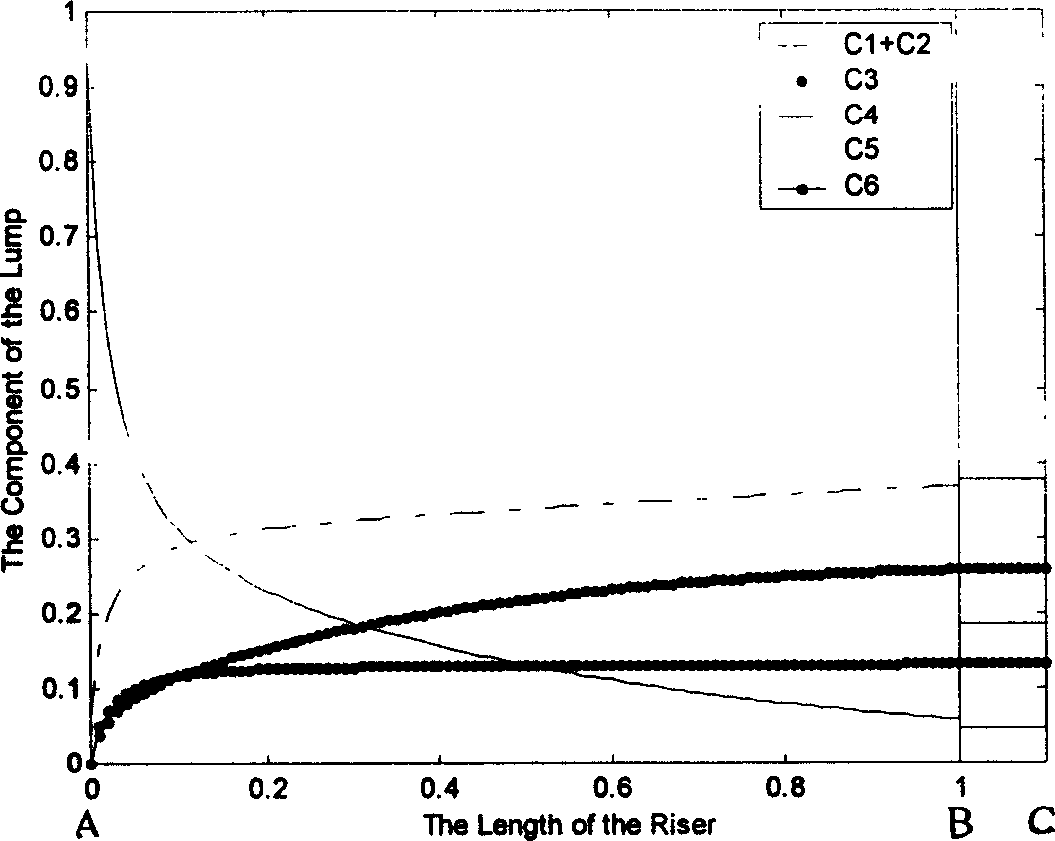

[0081] According to the modeling method f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com