Induction powered apparatus for overhead high tension transmission lines

A technology of inductive power acquisition and high-voltage power transmission, which is applied in the direction of battery circuit devices, circuit devices, inductors, etc., can solve the problems of increased weight of equipment, application restrictions, and increased workload of live work. The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

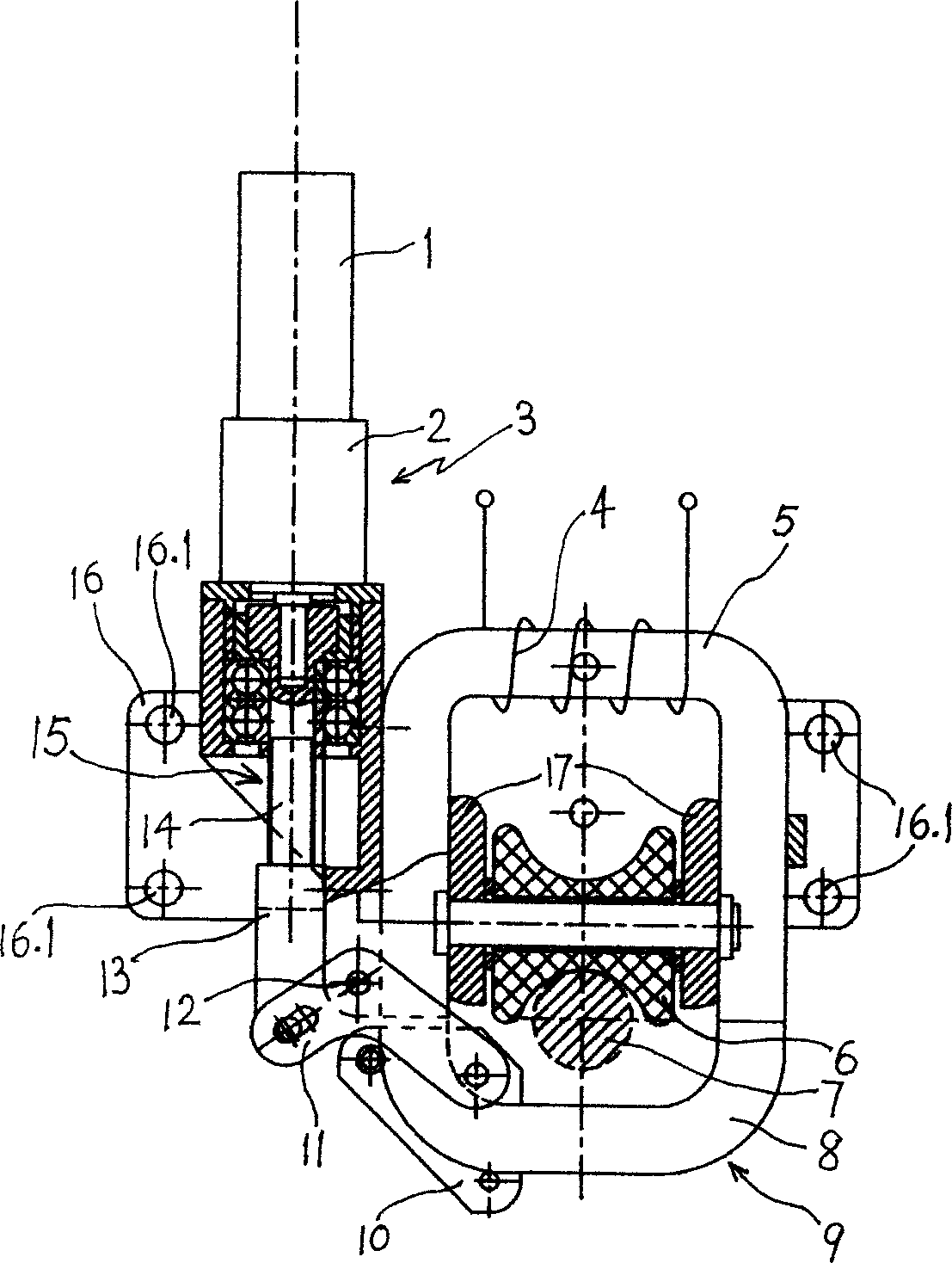

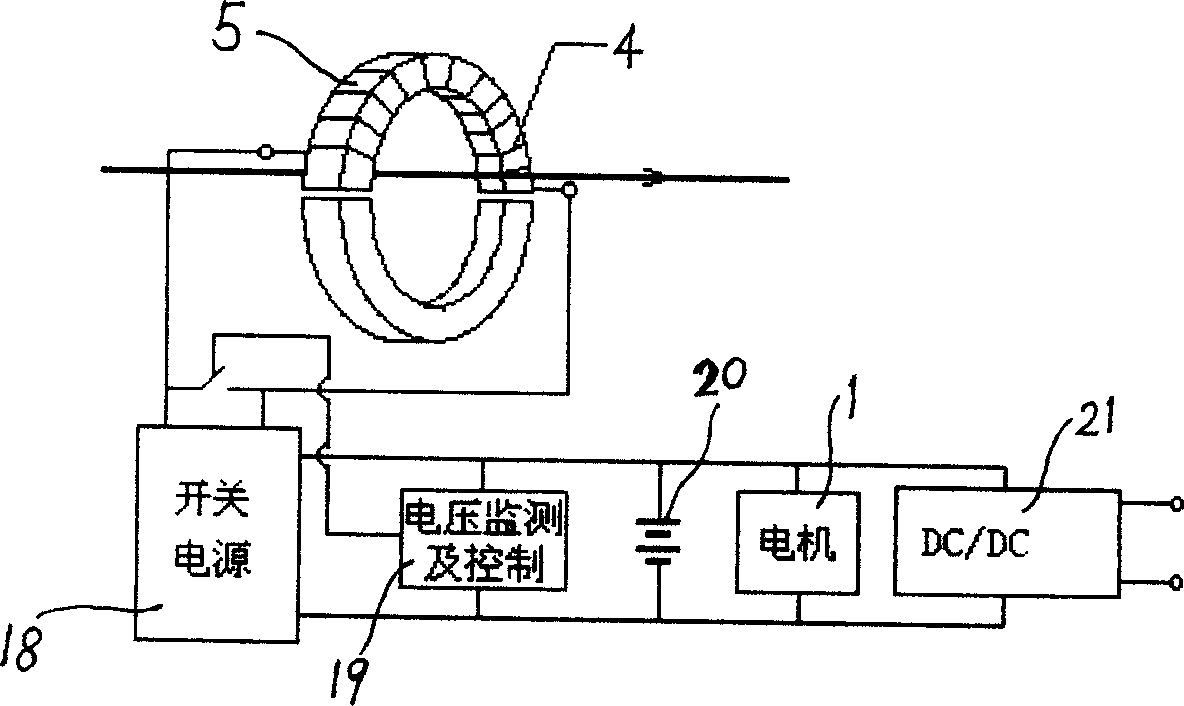

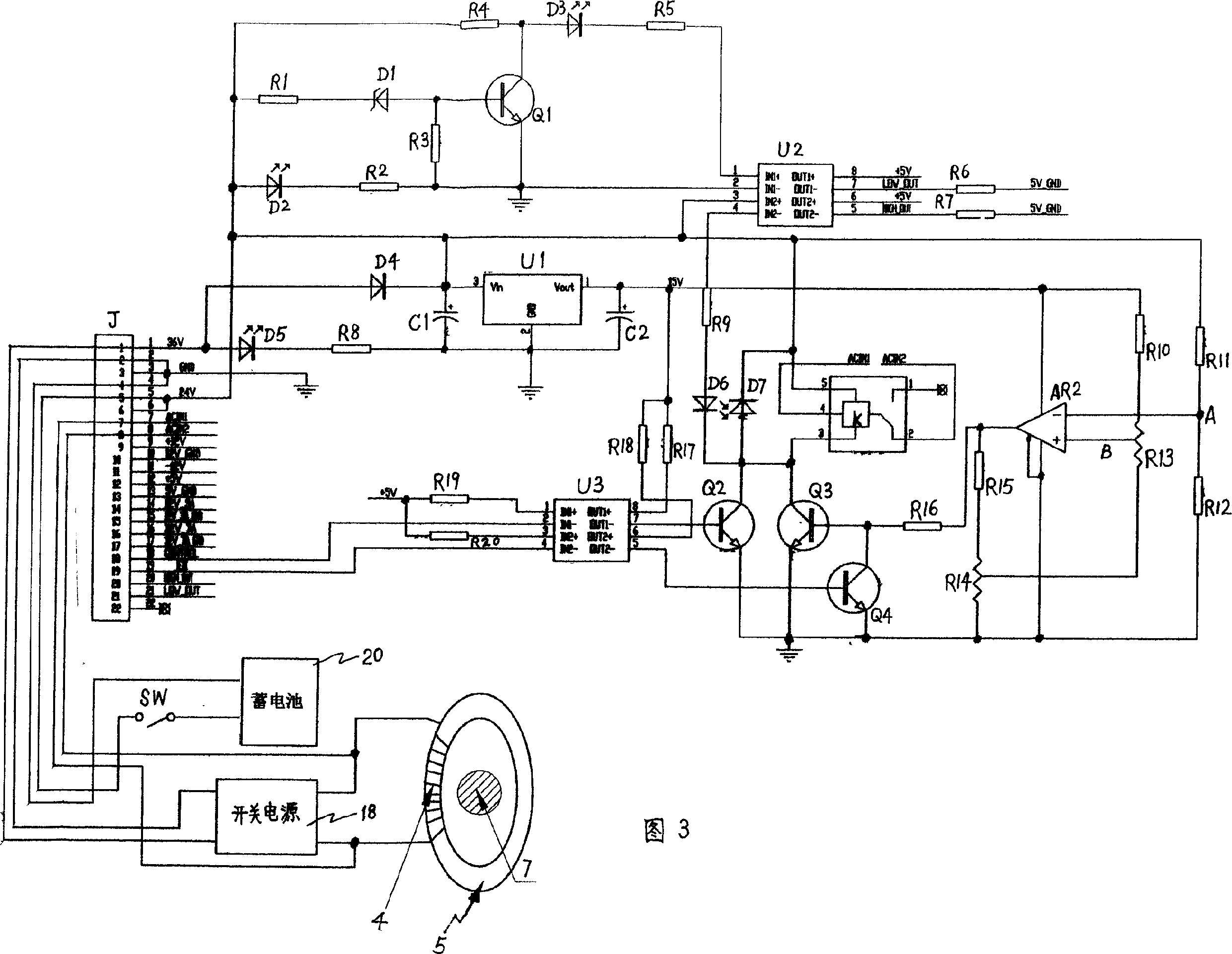

[0014] see Figure 1 to Figure 7 , the present invention is an induction power-taking device for overhead high-voltage transmission wires, which includes an iron core 5 on which a secondary side coil 4 is wound, and a walking rod riding on a power transmission wire 7 is arranged in the iron core 5. Wheel 6, the lower end of the iron core 5 is connected with the movable side 9 which can open the lower end of the iron core 5, and the driving mechanism 3 near the iron core 5 is opened or closed to the movable side 9, which is connected in parallel on the output circuit of the secondary side coil 4 There are switching power supply 18 , voltage monitoring and control device 19 , storage battery 20 , motor 1 and direct current-direct current (DC-DC) conversion device 21 .

[0015] A further technical solution can be: the actuator 3 includes a motor 1, a reducer 2 and a screw nut mechanism 15 driven by it, and the nut 13 pairs reciprocating on the screw rod 14 and one end of the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com