Dipolar permanent-magnet direct current motor

A DC motor and permanent magnet technology, applied in DC commutators, electrical components, electromechanical devices, etc., can solve problems such as backward structure, unreasonable design of magnetic circuit, and low efficiency of DC motor power conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

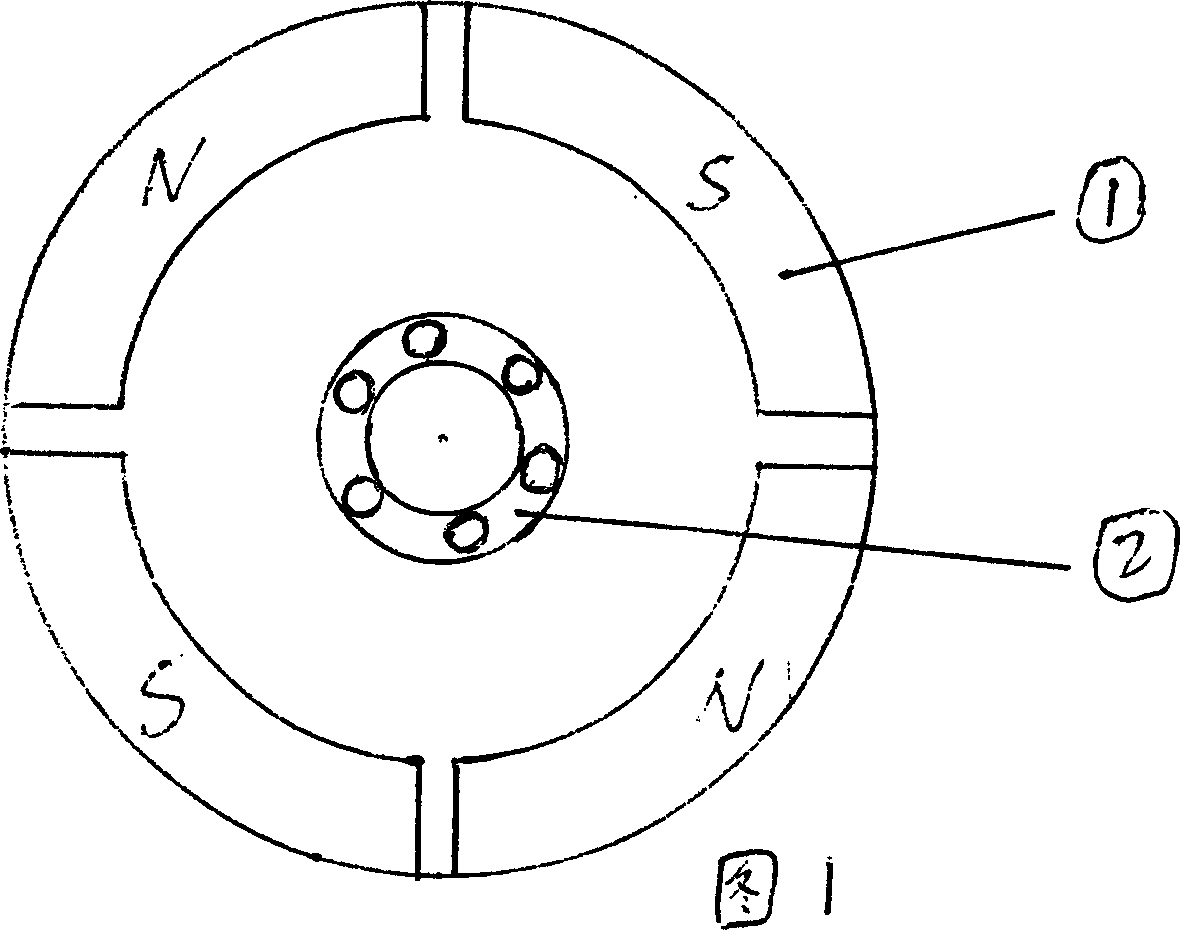

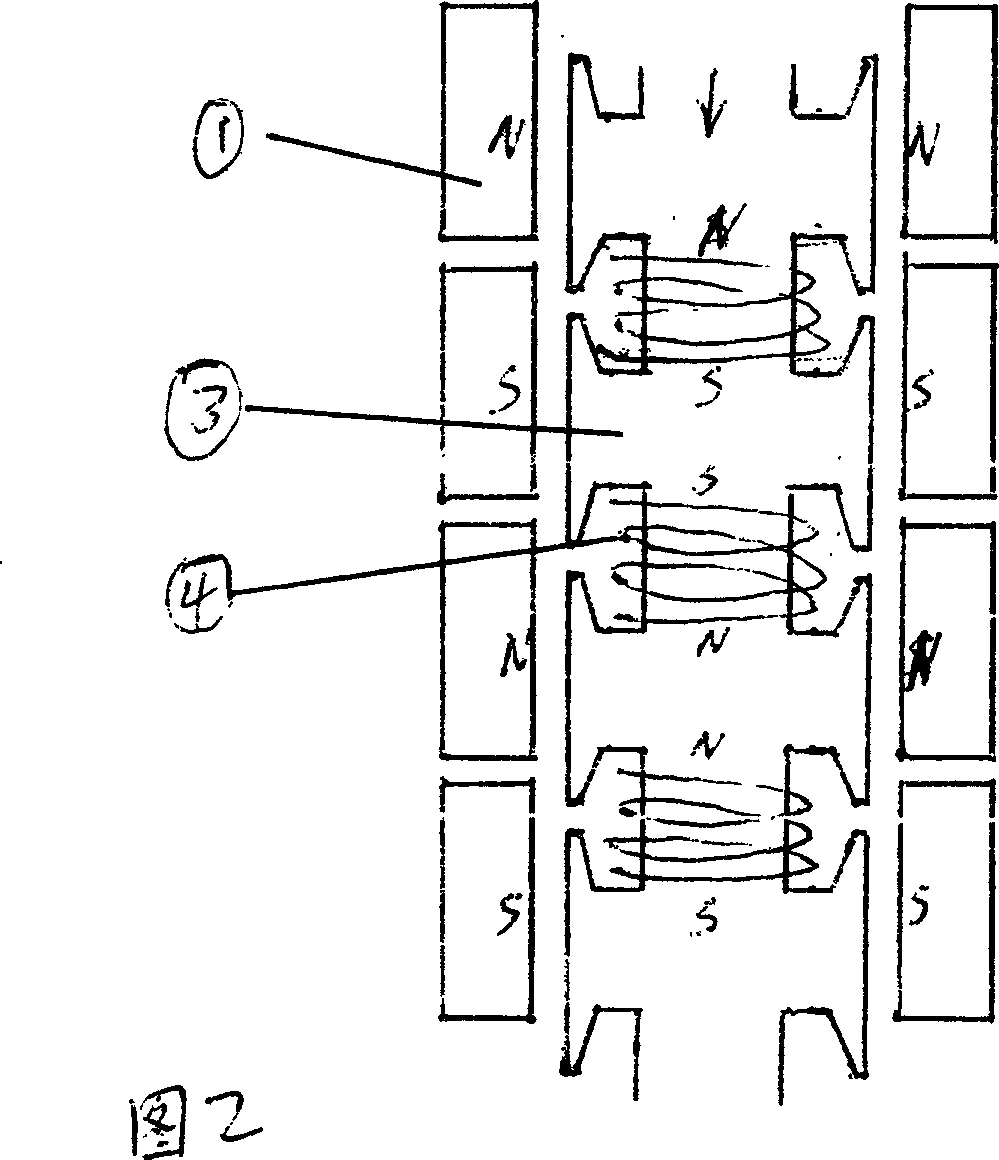

[0007] Figure 1 is a schematic plan view of the inner stator of the end cover; (1) represents the permanent magnet pole of the stator; (2) represents the bearing in the middle of the end cover. Figure 2 shows the schematic diagram of the rotor circumference surface development; (2) shows the stator permanent magnet pole; (3) shows the rotor core; (4) shows the coil.

[0008] To sum up, the present invention can use simple structural design, so that the product of the present invention can fully utilize permanent magnet energy and electric energy, greatly reduce cost, work stably and reliably, and be easy to use, and solve the problem of electric vehicle power, etc. The present invention is a novel, progressive and practical new design. The above descriptions are the specific embodiments of the present invention and the applied technical principles. If the equivalent changes are made according to the concept of the present invention, and the functions produced by it still do no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com