Diamond saw bit and its manufacturing method

A technology of diamond saw blades and production methods, which is applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of passive work progress, expensive raw materials, and high cost in steelworks, and achieve saving manpower and material resources and improving the operating environment , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

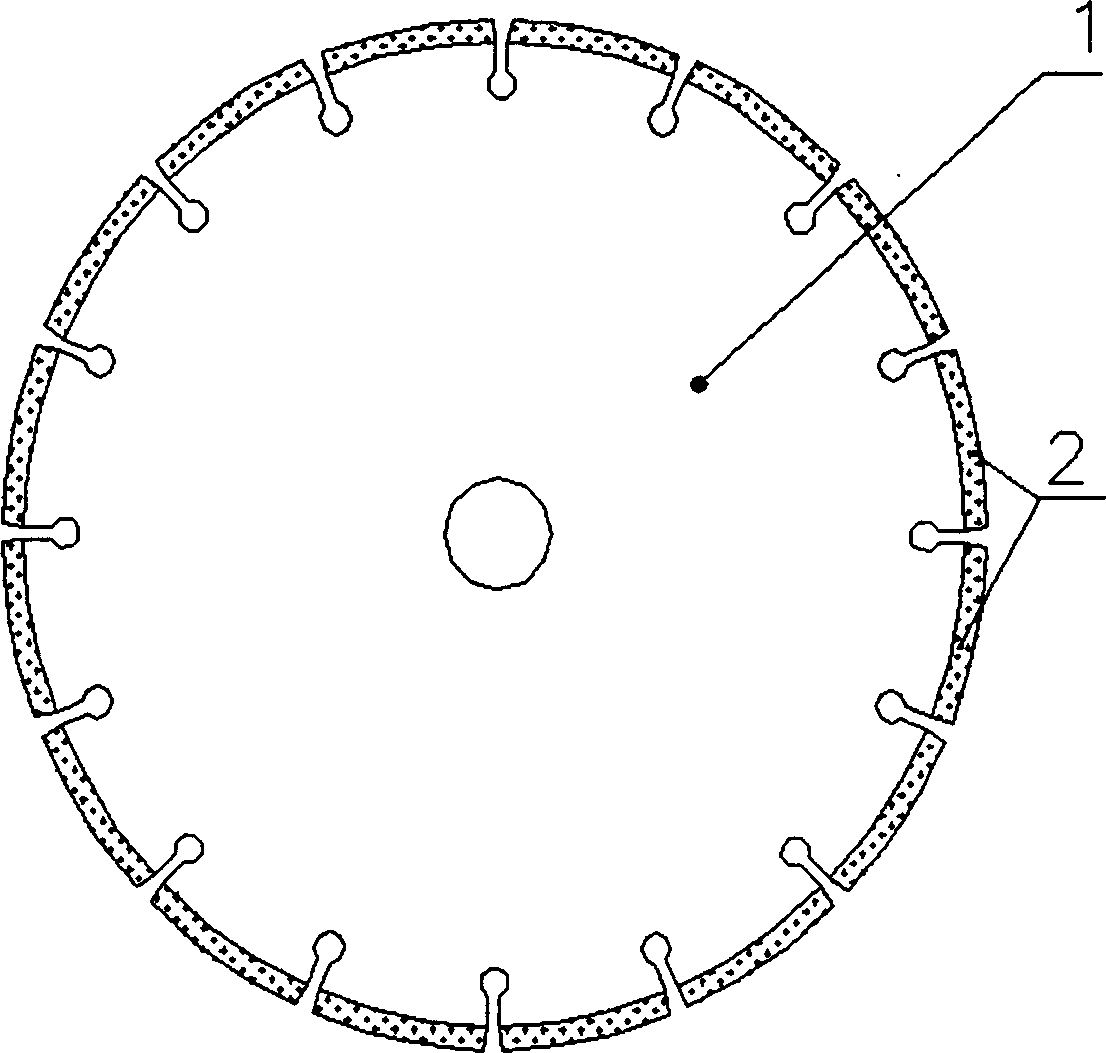

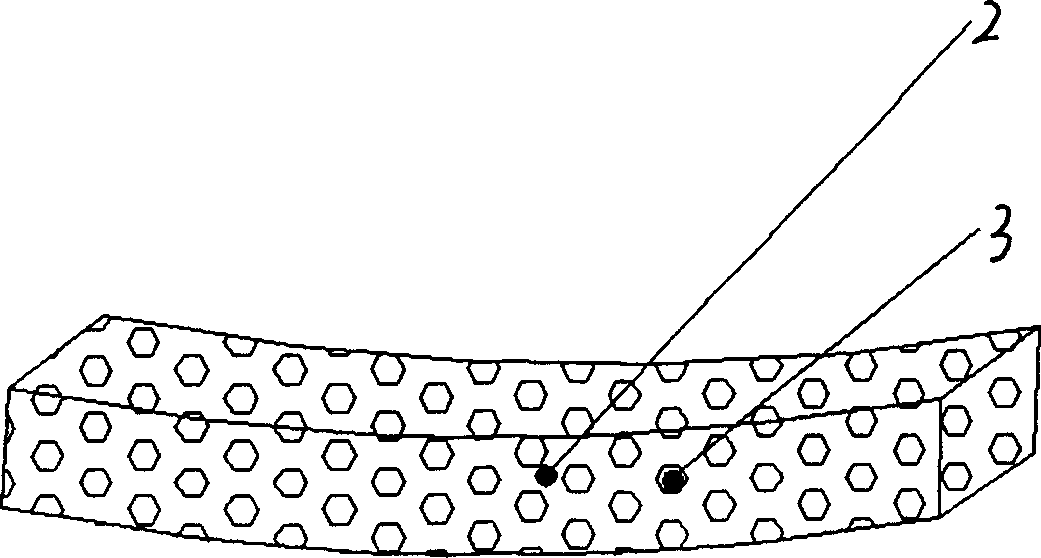

[0019] Such as figure 1 , figure 2 As shown, the diamond saw blade of the present invention is composed of a steel substrate 1 and an alloy bit 2 impregnated with diamond particles 3, wherein the alloy bit 2 is composed of the following components by weight: 15 grams of tungsten powder and 25 grams of cobalt powder , 45 grams of copper powder, 15 grams of tin powder, 25 grams of iron powder, the purity of the above metal powder is 99.65%.

[0020] The production method of the present invention is as follows: 15 grams of tungsten powder with a purity of 99.65%, 25 grams of cobalt powder, 45 grams of copper powder, 15 grams of tin powder, 25 grams of iron powder and diamond particles are fully mixed and put into the mold together. Inside, heated at a temperature of 850°C, and the hot pressing pressure is 350kgf / cm 2 , At 4 tons / cm 2 It is formed under the pressure of a high pressure to obtain an alloy cutter head, and finally the alloy cutter head is brazed on the outer peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com