Built-in board and its coreboard and making method of coreboard

A core material and interior decoration technology, applied in the direction of building structure, building components, layered products, etc., can solve the problems of honeycomb structure condensation, temperature difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An interior panel, its core material, and a method of manufacturing the core material according to one embodiment of the present invention will be described.

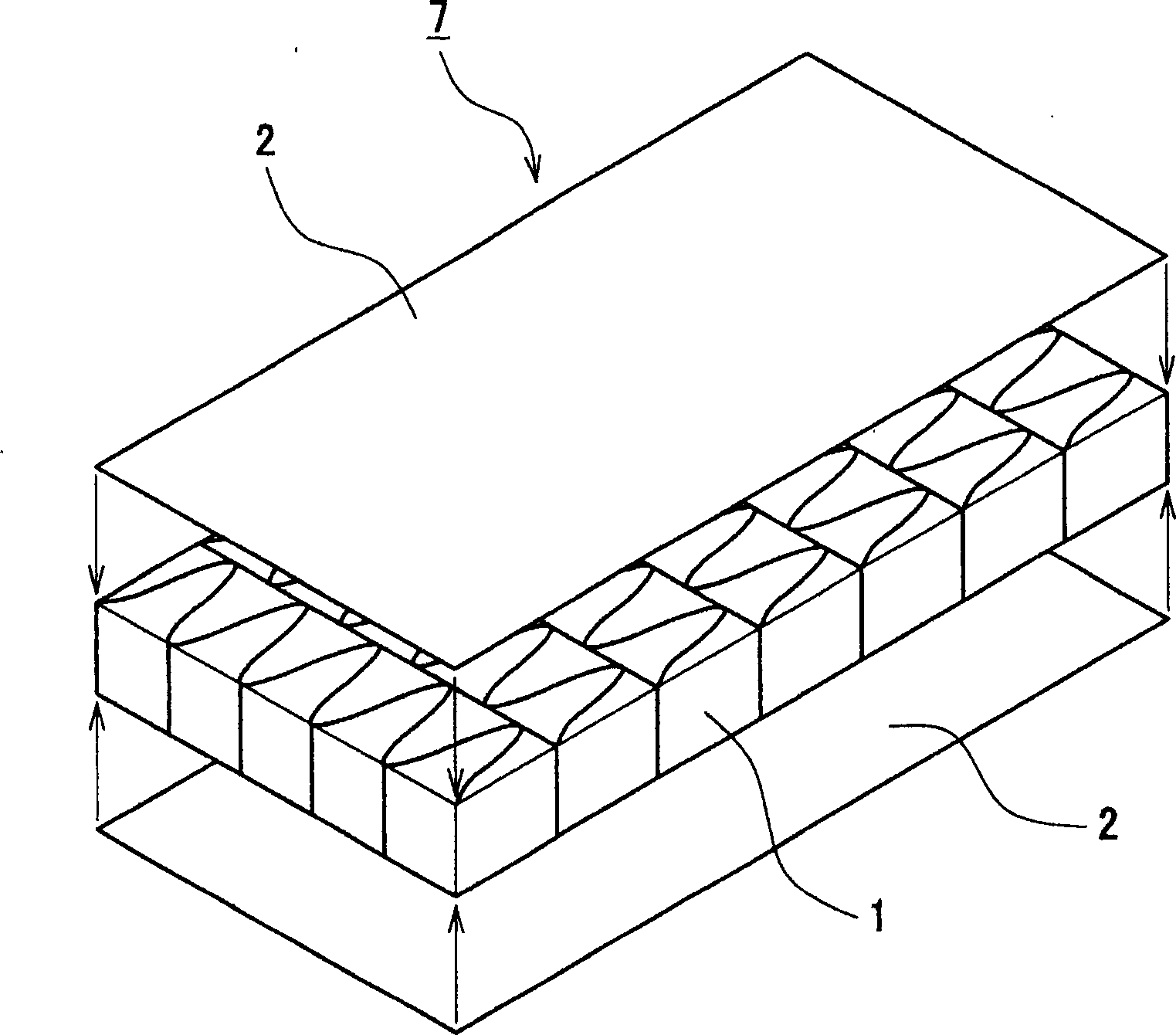

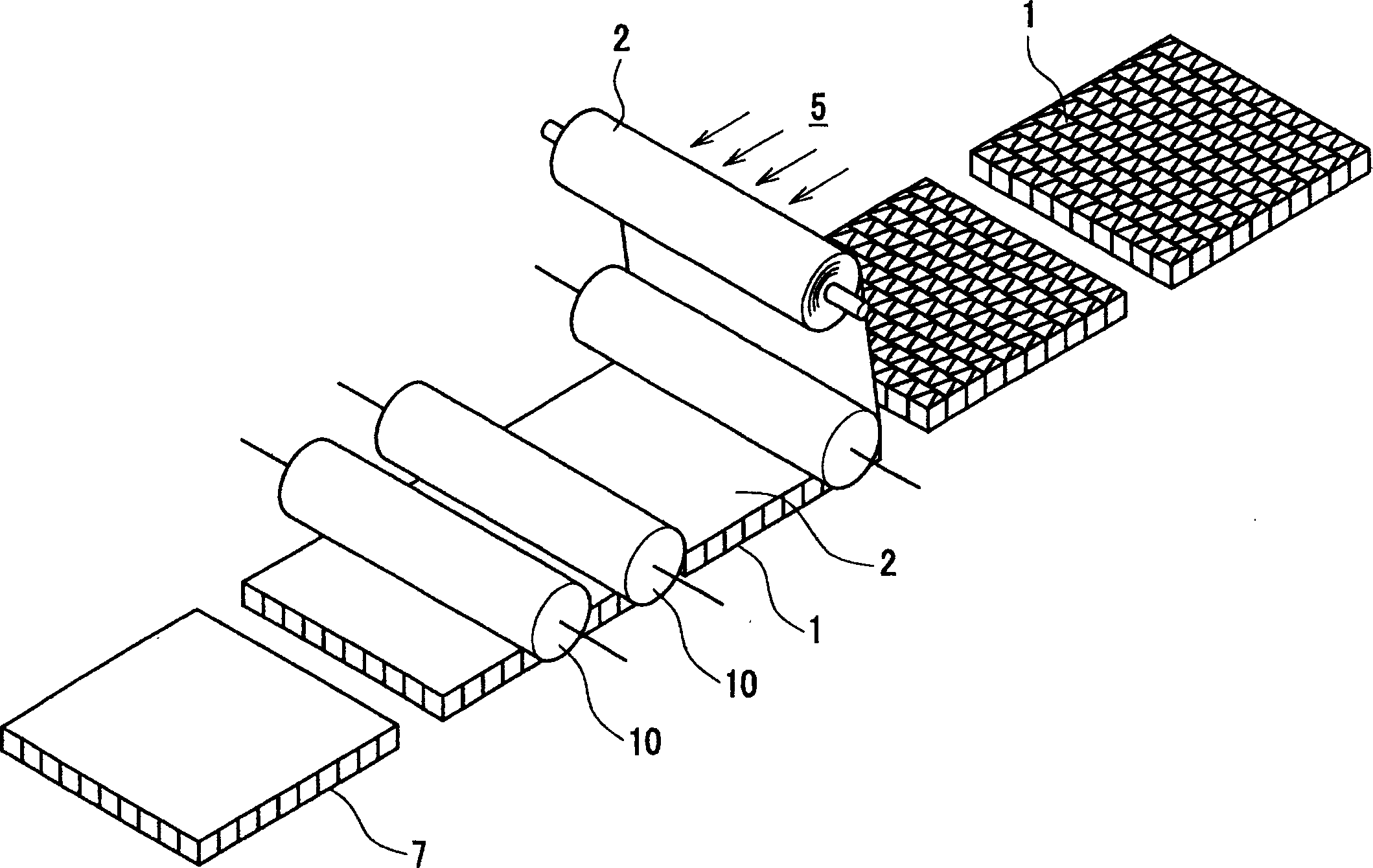

[0018] exist figure 1 The middle shows the core material structure of this embodiment. Such as figure 1 As shown, the sheet material 2 is adhesively fixed on both surfaces (the front surface and the back surface) of the honeycomb structure 1 to form the core material 7 . As the adhesive for bonding the sheet 2 to both upper surfaces of the honeycomb structure 1, a non-aqueous adhesive can be used. Since the non-aqueous adhesive will not emit water when hardened, after the sheet material 2 is fixed on both surfaces of the honeycomb structure 1, the water will not be sealed inside the honeycomb structure 1 .

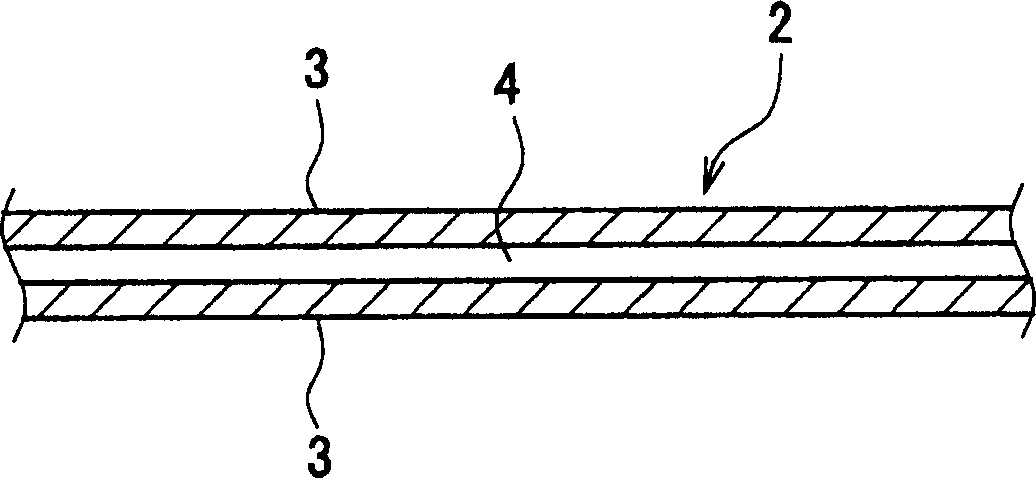

[0019] In this embodiment, the structure and material of the sheet 2 are not particularly limited. For example, by coating the non-aqueous adhesive on the entire surface of the sheet material 2, the non-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com