Solid polymer cell assembly

一种固体高分子、组合体的技术,应用在固体电解质燃料电池、燃料电池分组、固体电解质电池的电解质处理等方向,能够解决维修困难等问题,达到提高排水性、简单构造、容易且良好安装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

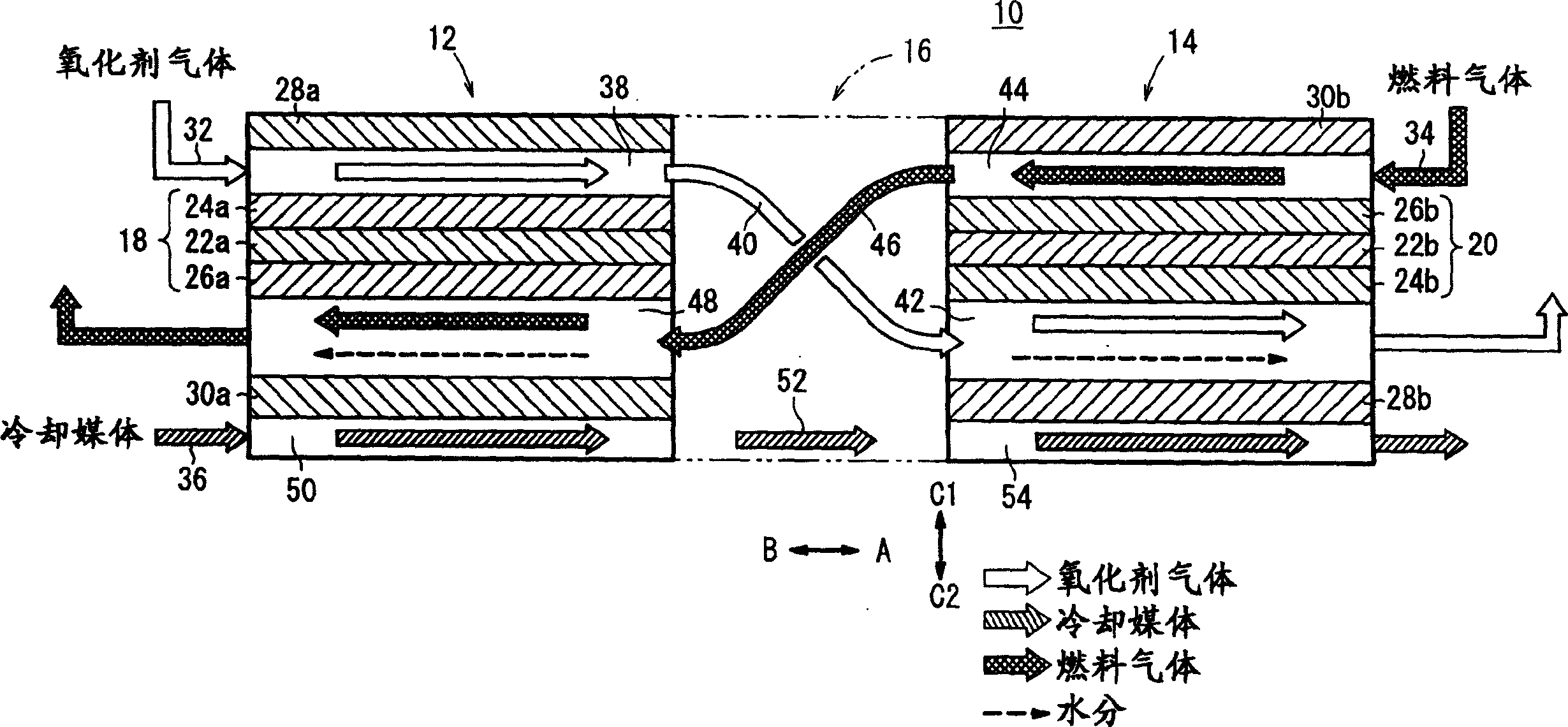

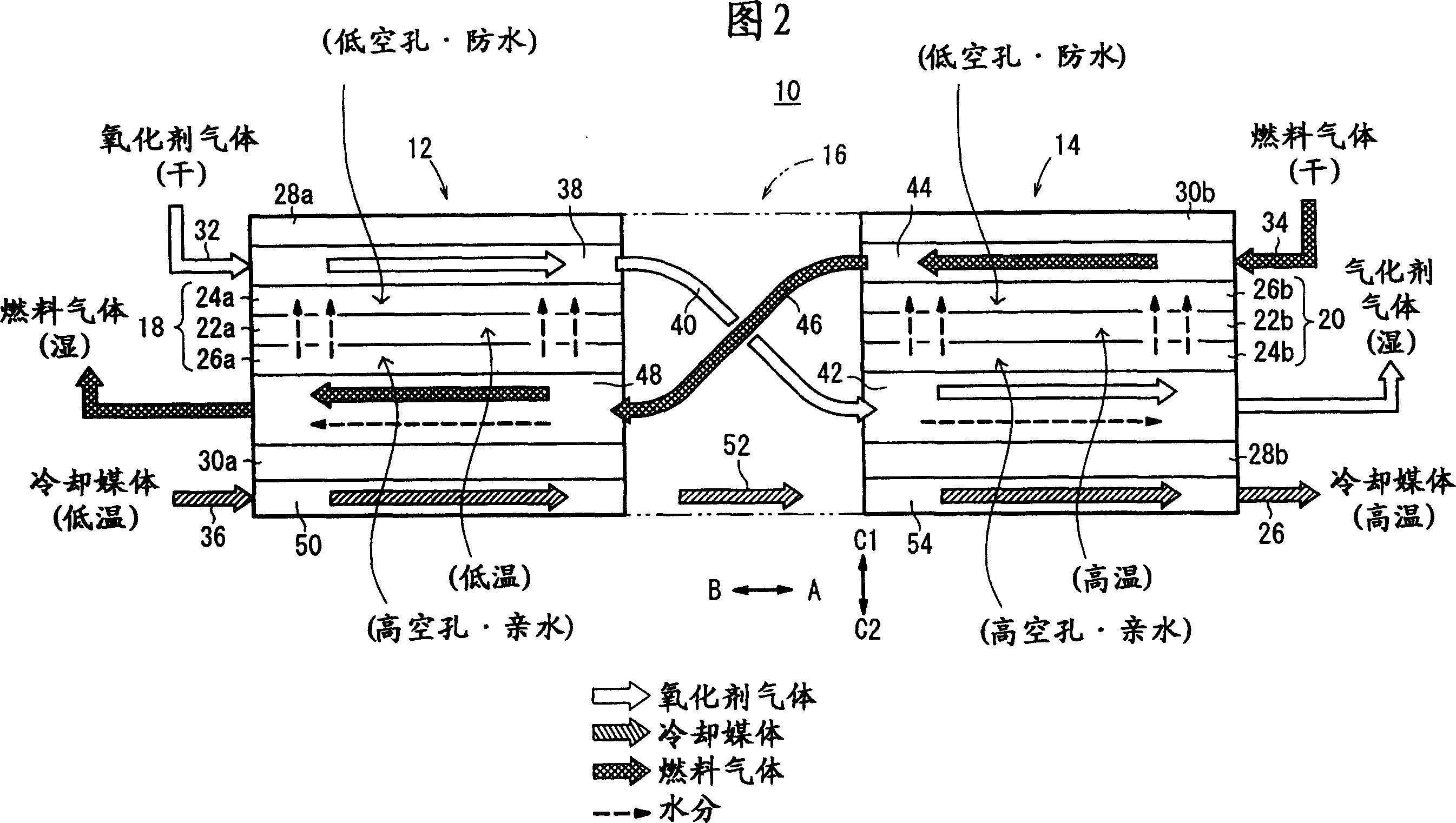

[0027] figure 1 It is a schematic structural view of main parts of the solid polymer battery assembly 10 according to the first embodiment of the present invention.

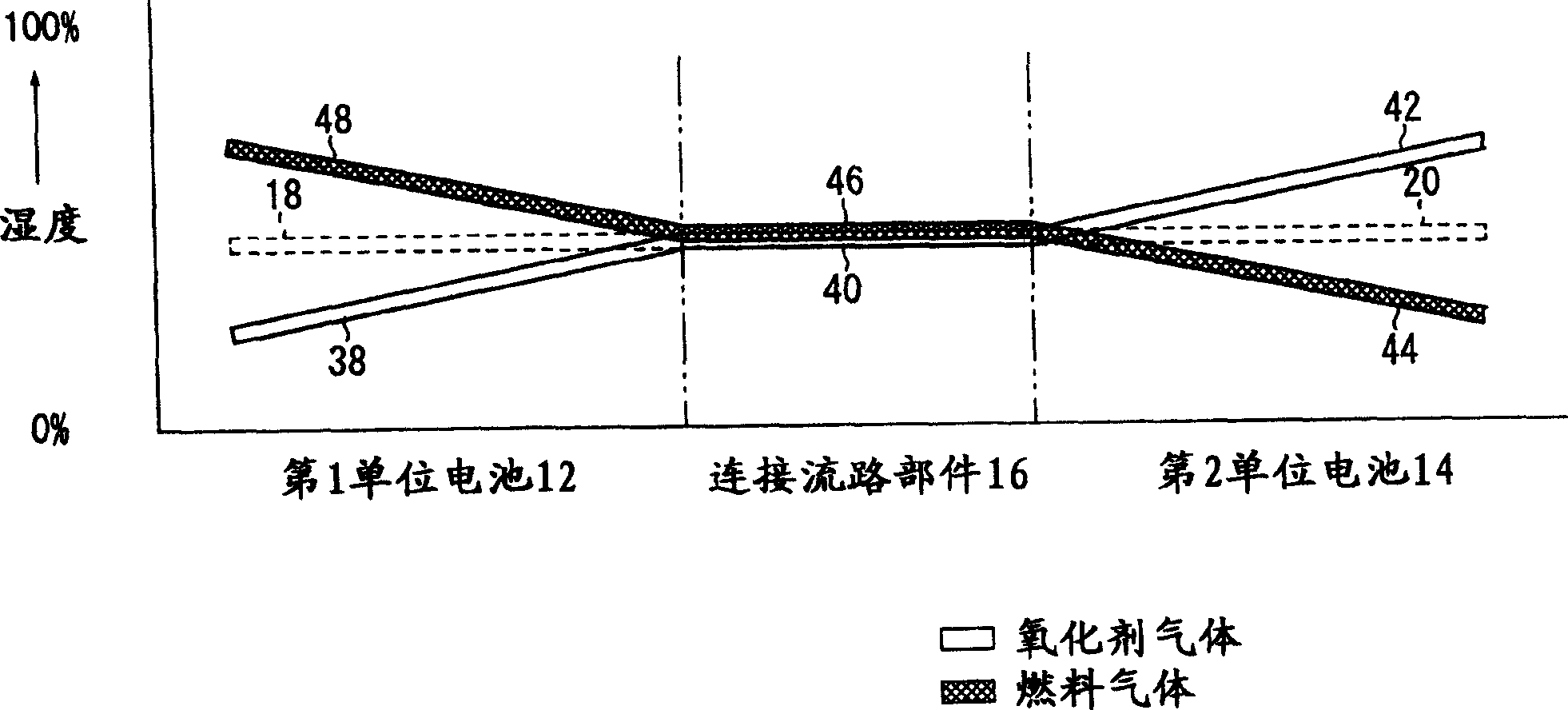

[0028] The battery assembly 10 is configured by arranging a plurality of unit cells, for example, a first unit cell 12 and a second unit cell 14 with their electrode surfaces parallel to each other. Between the first and second unit cells 12 and 14, a connection channel member 16 is arranged. The first unit cell 12 constitutes a unit cell on the upstream side in the flow direction (arrow A direction) of the oxidizing gas (reactive gas). The second unit cell 14 constitutes a unit cell on the downstream side in the flow direction of the oxidizing gas.

[0029]The first and second unit cells 12 and 14 are provided with first and second junction bodies 18 and 20 . The first and second assemblies 18, 20 have, for example, solid polymer electrolyte membranes 22a, 22b impregnated with water in perfluorosulfonic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com