Printed circuit board structure for motor driving device

A printed circuit board and circuit board technology, which is applied in the structural connection of printed circuits, printed circuits connected with non-printed electrical components, printed circuits, etc., to achieve the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

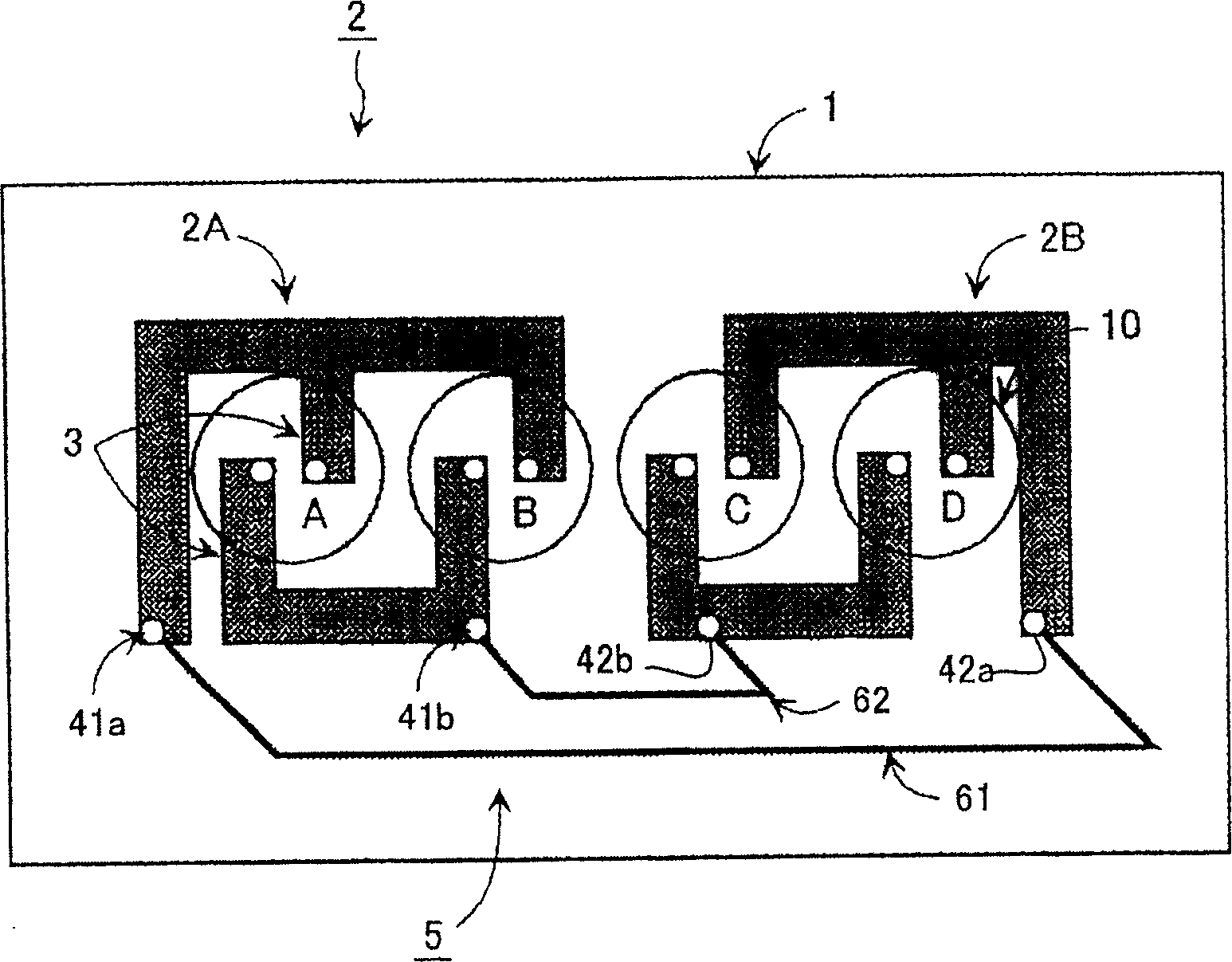

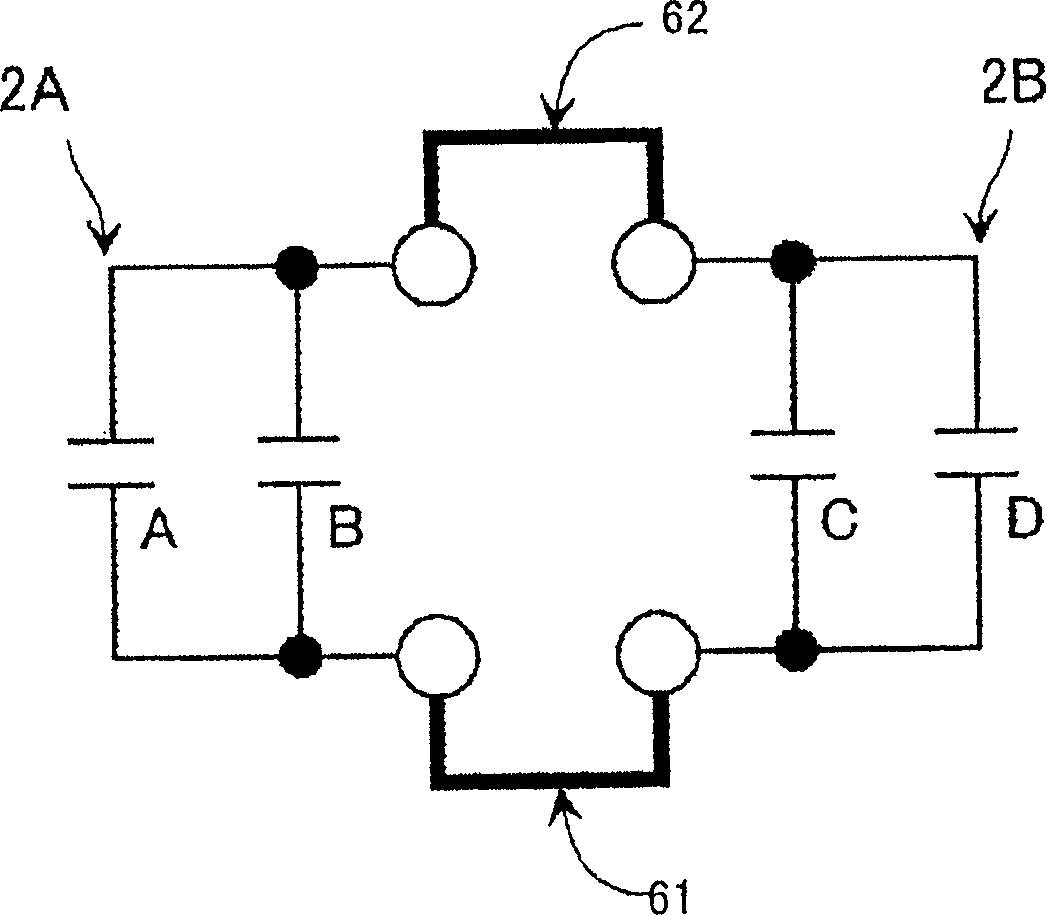

[0030] refer to Figure 1-4 A first embodiment of the present invention is described. Such as figure 1 As shown, the printed circuit board 2 of the first embodiment includes two conductive patterns 2A, 2B formed on the circuit board 1 and an optional connector 5 electrically connecting the conductive patterns 2A and 2B. In this embodiment, the optional connector 5 includes a shorting bar 6 .

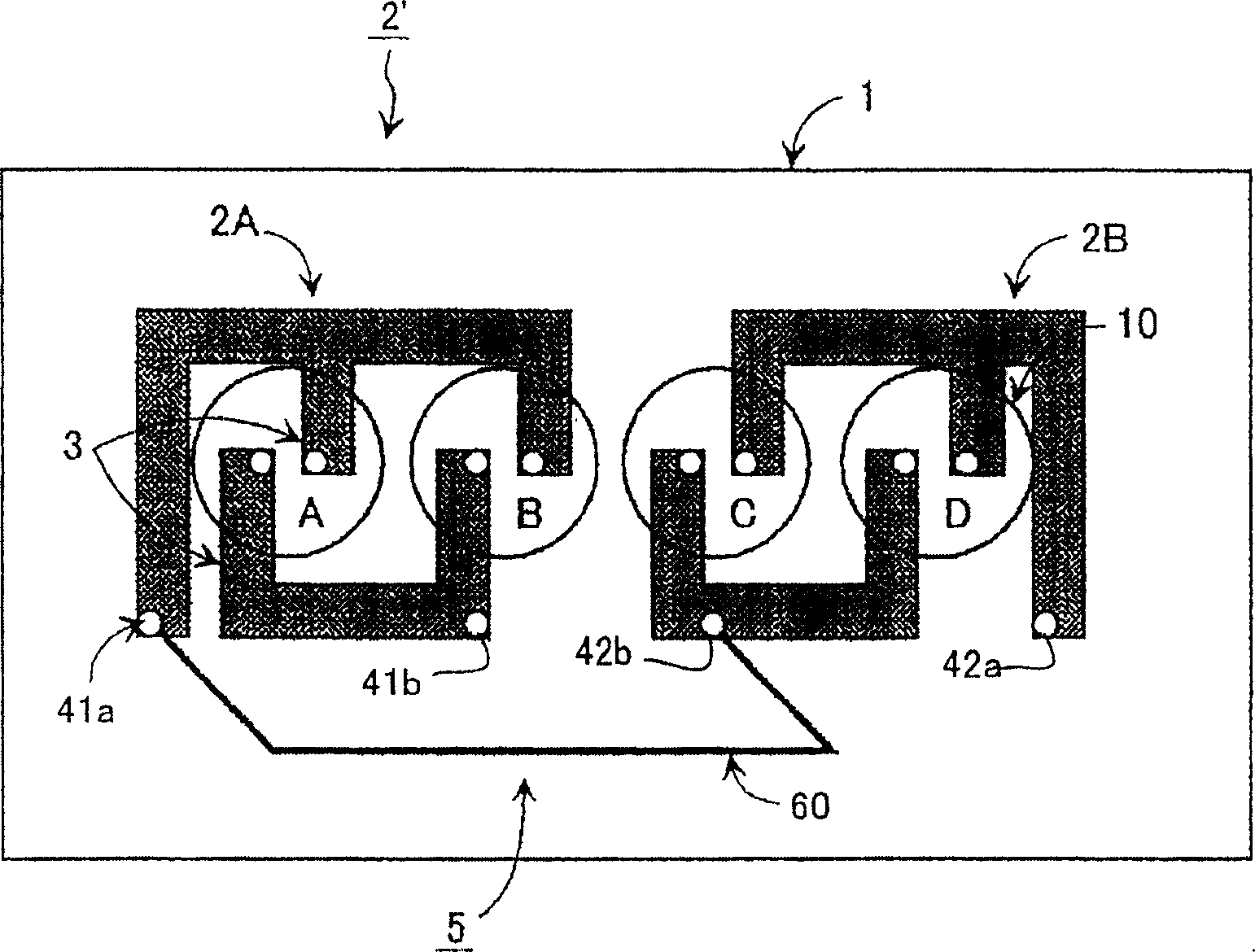

[0031] The two conductive patterns 2A and 2B formed on the circuit board 1 have substantially the same pattern, and each of the conductive patterns 2A and 2B has two pairs of electrodes 3 disposed oppositely. exist image 3 The printed circuit board 2' shown in has the same figure 1 The printed circuit board 2 shown in FIG. 2 has the same conductive patterns 2A and 2B, but they are connected differently by shorting bars and thus have a different capacitance than the printed circuit board 2 .

[0032] Two pairs of electrodes 3 provided in the conductive pattern 2A constitute a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com