Track circuit compensation capacitance testing device and method

A technology for compensating capacitors and track circuits, which is applied to railway signals, fault locations, transportation and packaging, etc., and can solve the problem of affecting the transmission characteristics of track circuits, track circuit information transmission, whether there is no test method for track circuit compensation capacitor failure, and affecting the normality of locomotive signals Work and other issues, to achieve high-speed and effective detection, novel ideas, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

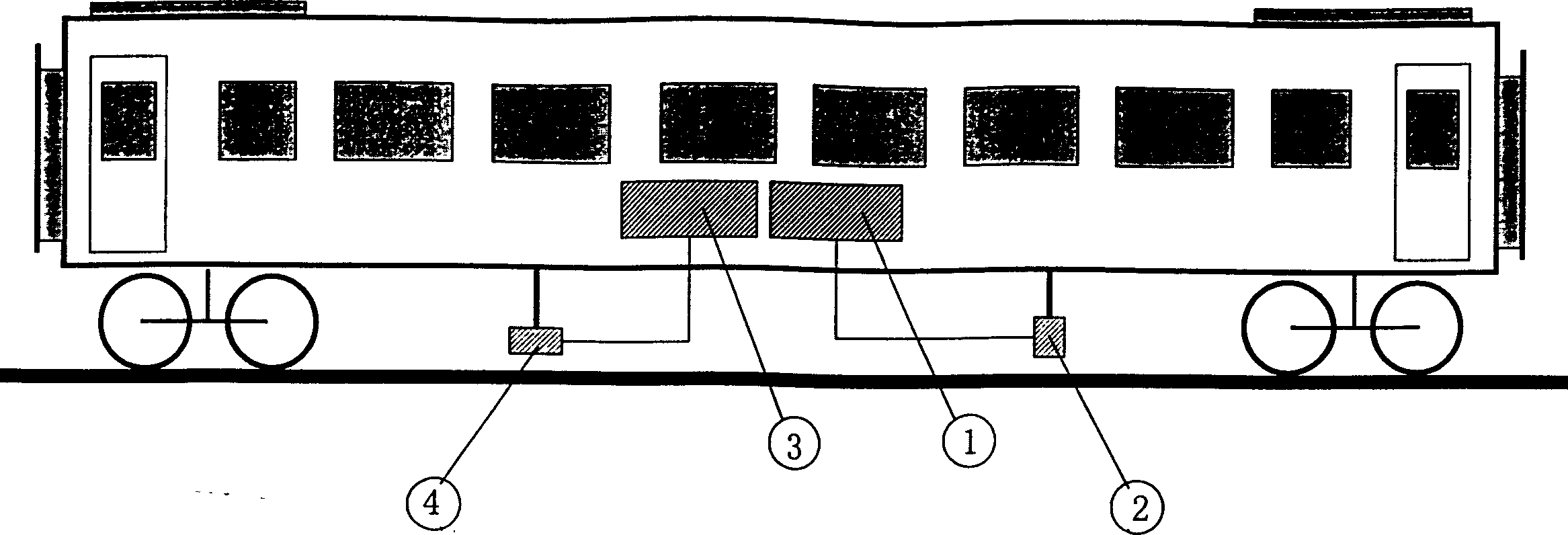

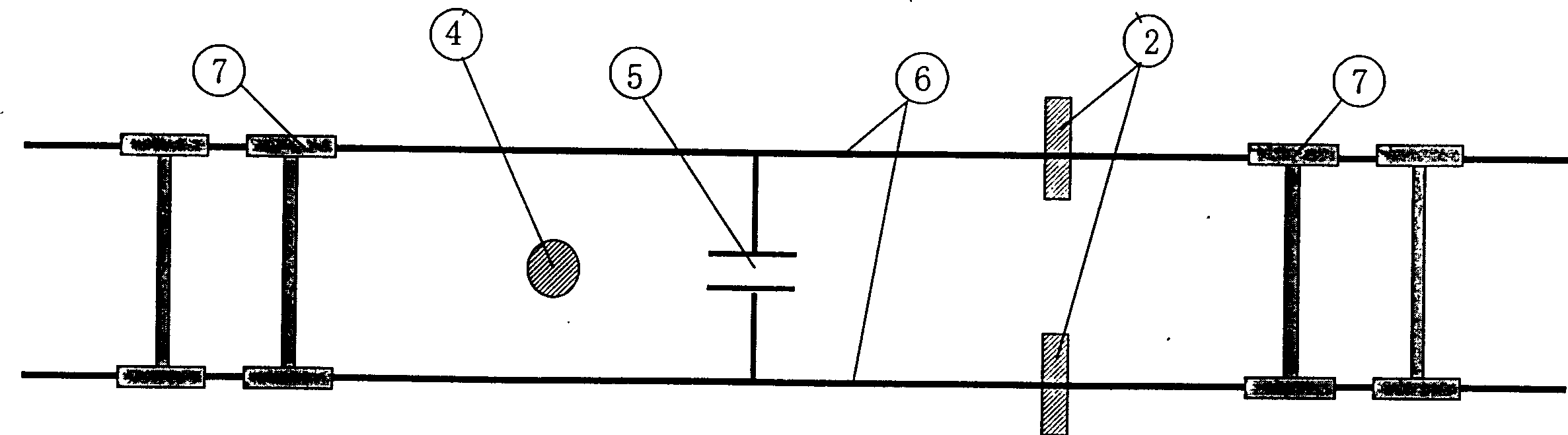

[0009] Such as figure 1 , 2 As shown, the present invention includes a signal transmission device 1 and a signal detection device 3 and a compensation capacitor 5 installed between the two rails. A transmitting sensor 2 is installed above the rails 6 on both sides and the bottom of the rolling stock between the two wheel pairs 7, and a receiving sensor 4 is installed at the middle position of the rails 6 on both sides and the bottom of the rolling stock between the two wheel pairs 7. The sending sensor 2 is connected to the signal sending device 1, and the signal detecting device 3 is connected to the receiving sensor 4.

[0010] The signal sending device 1 and the sending sensor 2, the signal detecting device 3 and the receiving sensor 4 are all commonly used devices in physical detection. The signal transmitting device 1 and the signal detecting device 3 are installed in a locomotive or vehicle. The transmitting sensor 2 is installed on the bottom of the locomotive or vehicle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com