Fuel pump noise-reduction apparatus in liquefied petroleum injection vehicle

A technology of liquefied petroleum and noise reduction device, applied in the field of operation devices, can solve the problems of output consumption, noise increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

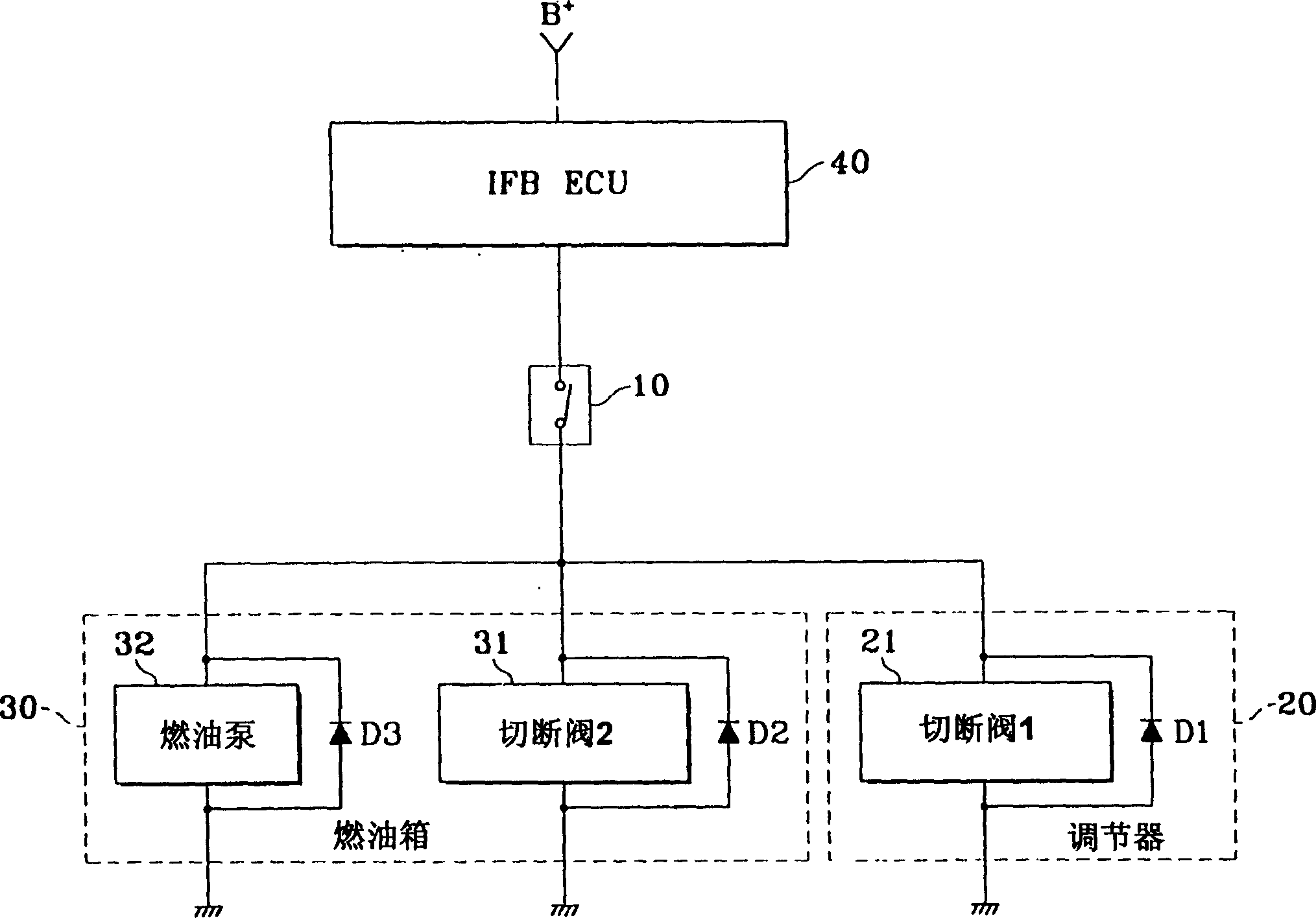

[0012] refer to figure 1 , a fuel pump muffler device according to an embodiment of the present invention includes an LPG switch 10, a cut-off valve 21 in a regulator 20, a cut-off valve 31 in a fuel tank 30, a fuel pump 32 in a fuel tank 30, and a fuel pump 32 for controlling the fuel interface box (IFB) electronic control unit (ECU) 40 .

[0013] The LPI engine has an engine management system (EMS) ECU and an IFB ECU to control the engine and fuel to activate the vehicle.

[0014] The LPG switch 10 is turned on or off according to the driver's operation. In case of an emergency or possible fuel leakage, the driver turns off the LPG switch 10 to stop fuel supply to avoid fuel leakage or any danger of the like.

[0015] When the battery power provided by the LPG switch 10 (B+, 12V power comes from the rear side of the main relay) is stopped by closing the LPG switch 10, the shut-off valve 21 of the regulator 20 and the shut-off valve 31 of the fuel tank 30 are closed to stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com