Engine start control system

A starting control device and engine technology, applied in the direction of engine control, engine starting, engine motor starting, etc., can solve the problem of not being able to distinguish between forward rotation and reverse rotation, so as to prevent useless power consumption and prevent power consumption , design and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

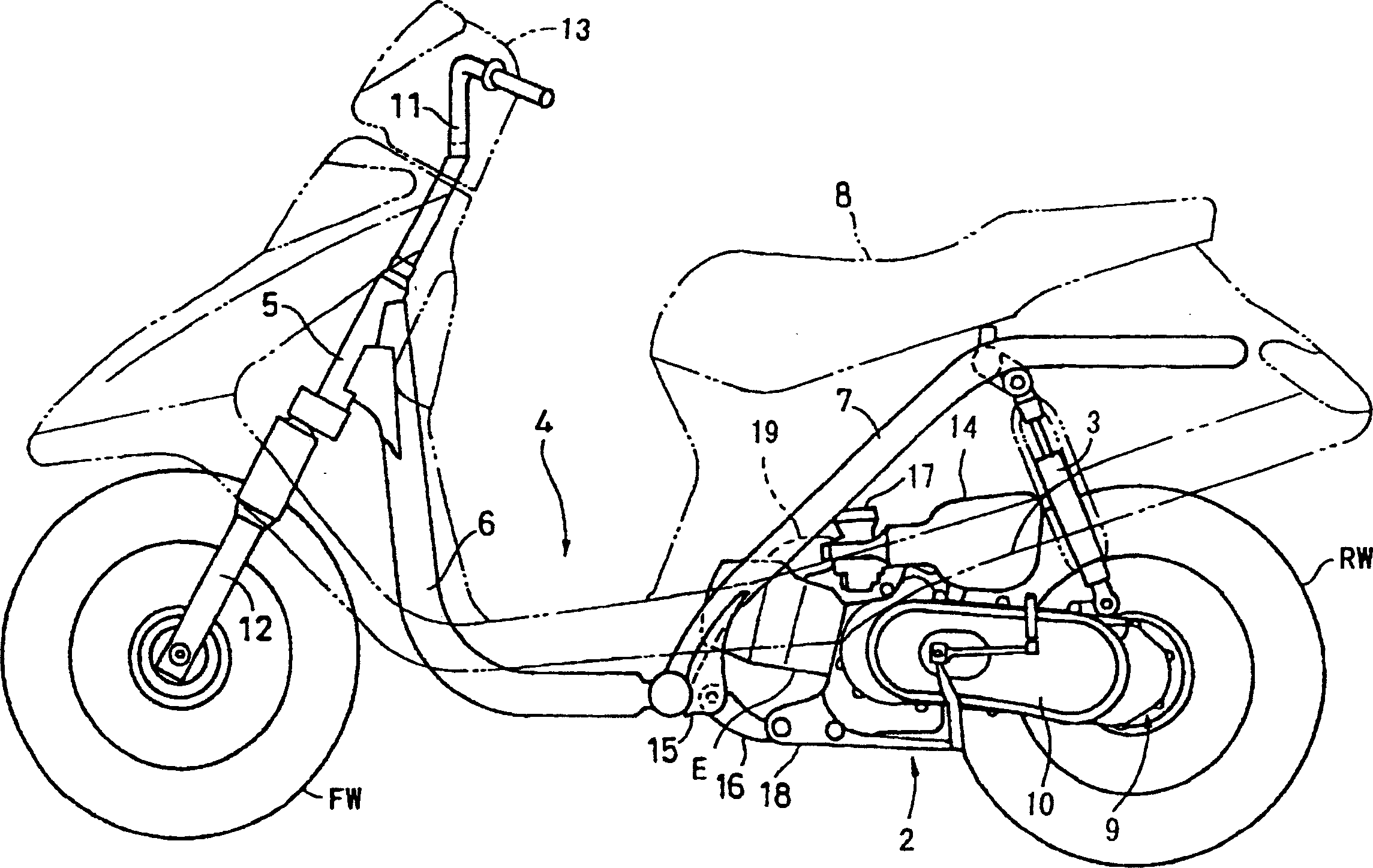

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. figure 1 It is an overall side view of a scooter-type motorcycle using the engine start control device of the present invention.

[0027] The front part of the vehicle body and the rear part of the vehicle body are connected by a lower floor part 4 , and the frame constituting the frame of the vehicle body is roughly composed of a down tube 6 and a main pipe 7 . A fuel tank and a storage box (both not shown) are supported by a main pipe 7, and a seat 8 is arranged above it.

[0028] A steering head 5 is pivotally supported at the front of the vehicle body, a handle 11 is provided above, and a front fork 12 extends downward, and a front wheel FW is pivotally supported at the lower end thereof. The upper part of the handle 11 is covered by a handle cover 13 which also serves as a dashboard. A bracket 15 protrudes from the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com