Method for realizing zero leakage and non-contact mechanical seal

A mechanical seal and zero-leakage technology, which is applied to engine seals, mechanical equipment, engine components, etc., can solve the problems of general load capacity, failure to achieve zero leakage, lack of upstream pumping capacity, etc., to prolong service life and enhance operation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention can adopt the laser processing method to realize the design scheme of the sealing ring surface. Laser processing is flexible and easy to control, and can realize the processing of the desired shape.

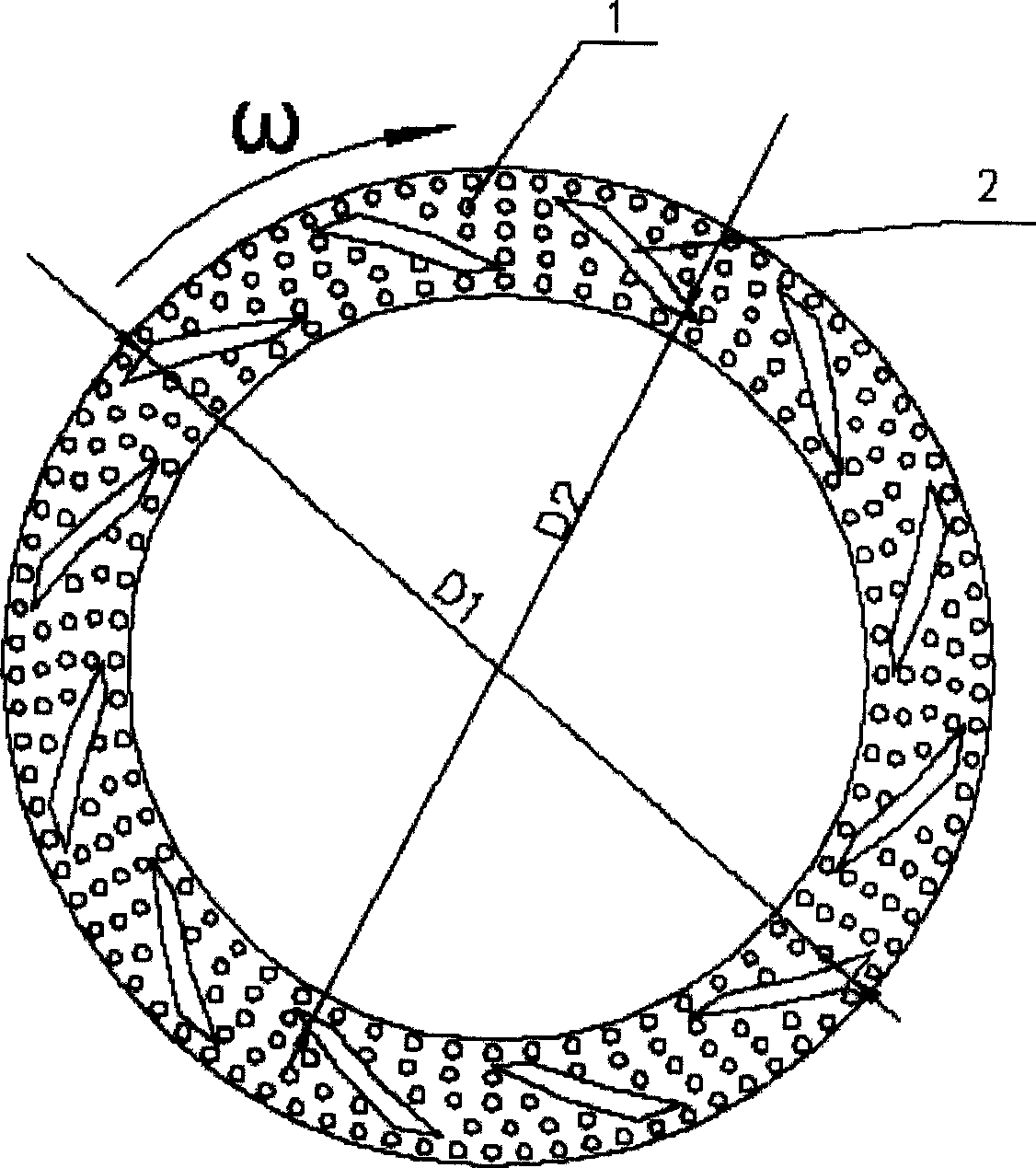

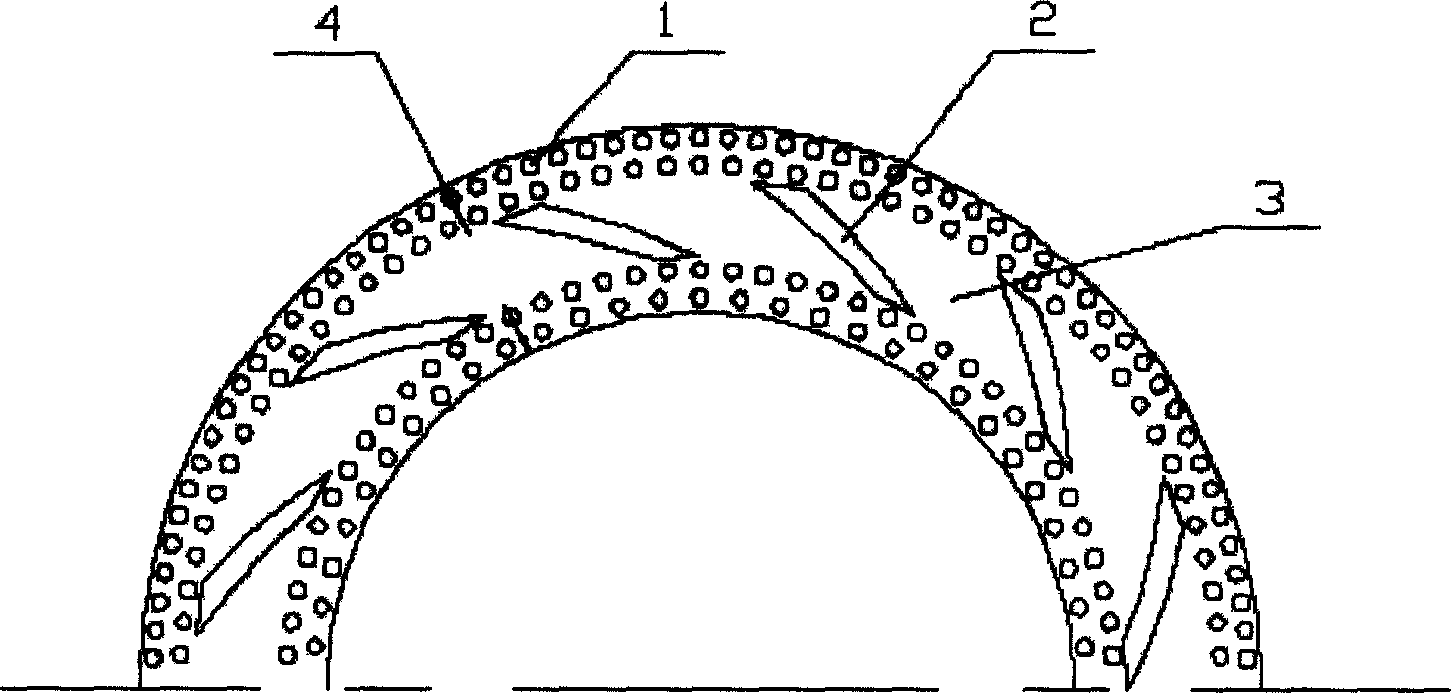

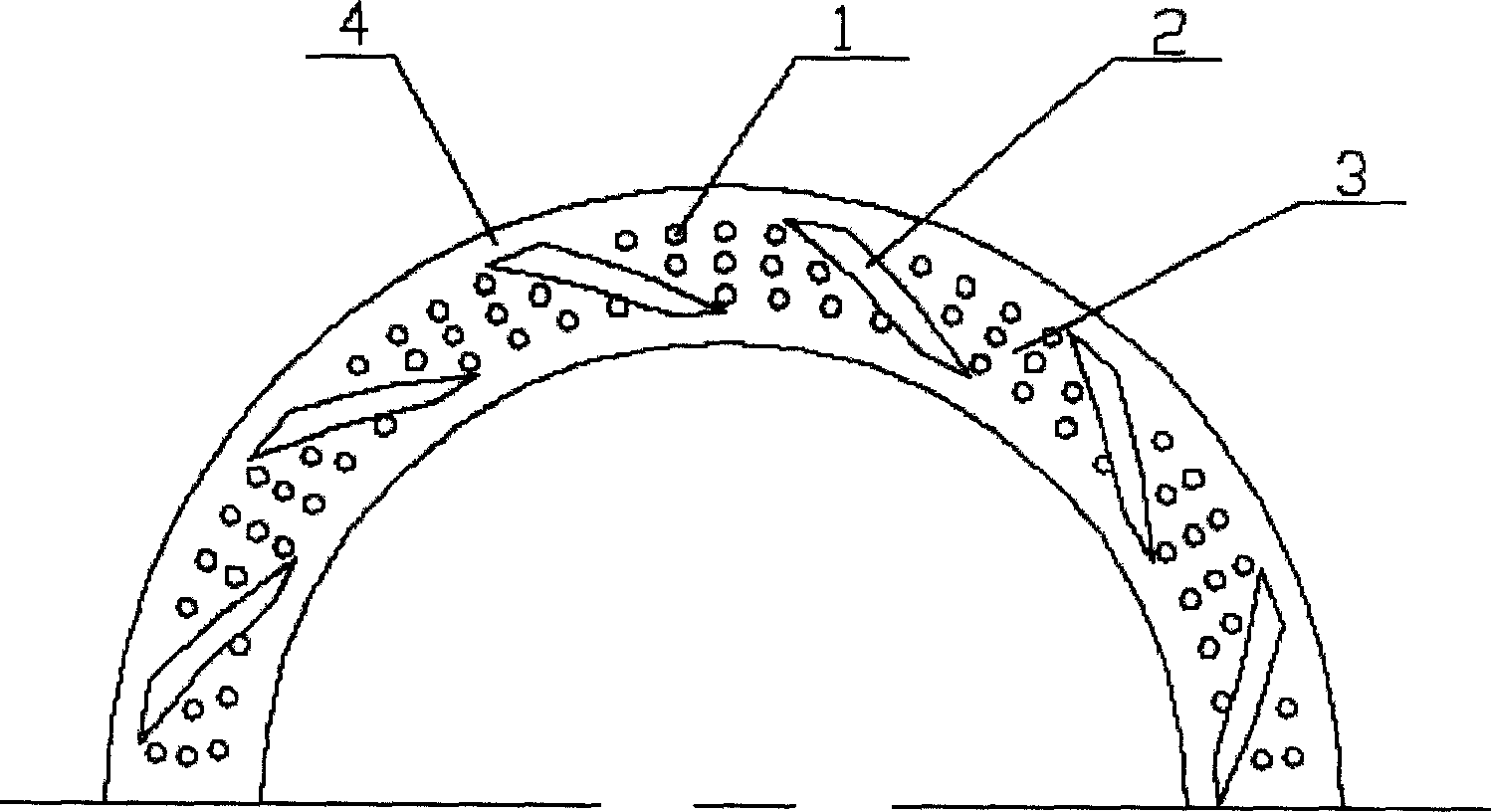

[0020] Embodiment A micro-lubrication chamber (1) evenly distributed in the non-pumping groove area and a pumping groove (2) in the middle of the sealing ring are provided on the dynamic ring of the mechanical seal, see figure 1 . The opening of lubricating chamber (1) and pumping groove (2) can be divided into two steps. The first step is to set microscopic lubricating chambers (1) in all areas of the sealing ring. The diameter d of these lubricating chambers (1) is 20-80um, the depth h1 is: 5-20um, and the distance L between the lubricating chambers (1) is 100~300um, such as Figure 7 . The second step is to set up a pumping groove (2) in the middle area of the sealing ring. The depth h2 of the pumping groove (2) is slightly greater than the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com