Direct type backlight

A backlight, direct-type technology, applied in optics, light guides, light sources, etc., can solve the problems of increased number of backlight components, increased assembly costs, and decreased uniformity of transmitted light diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

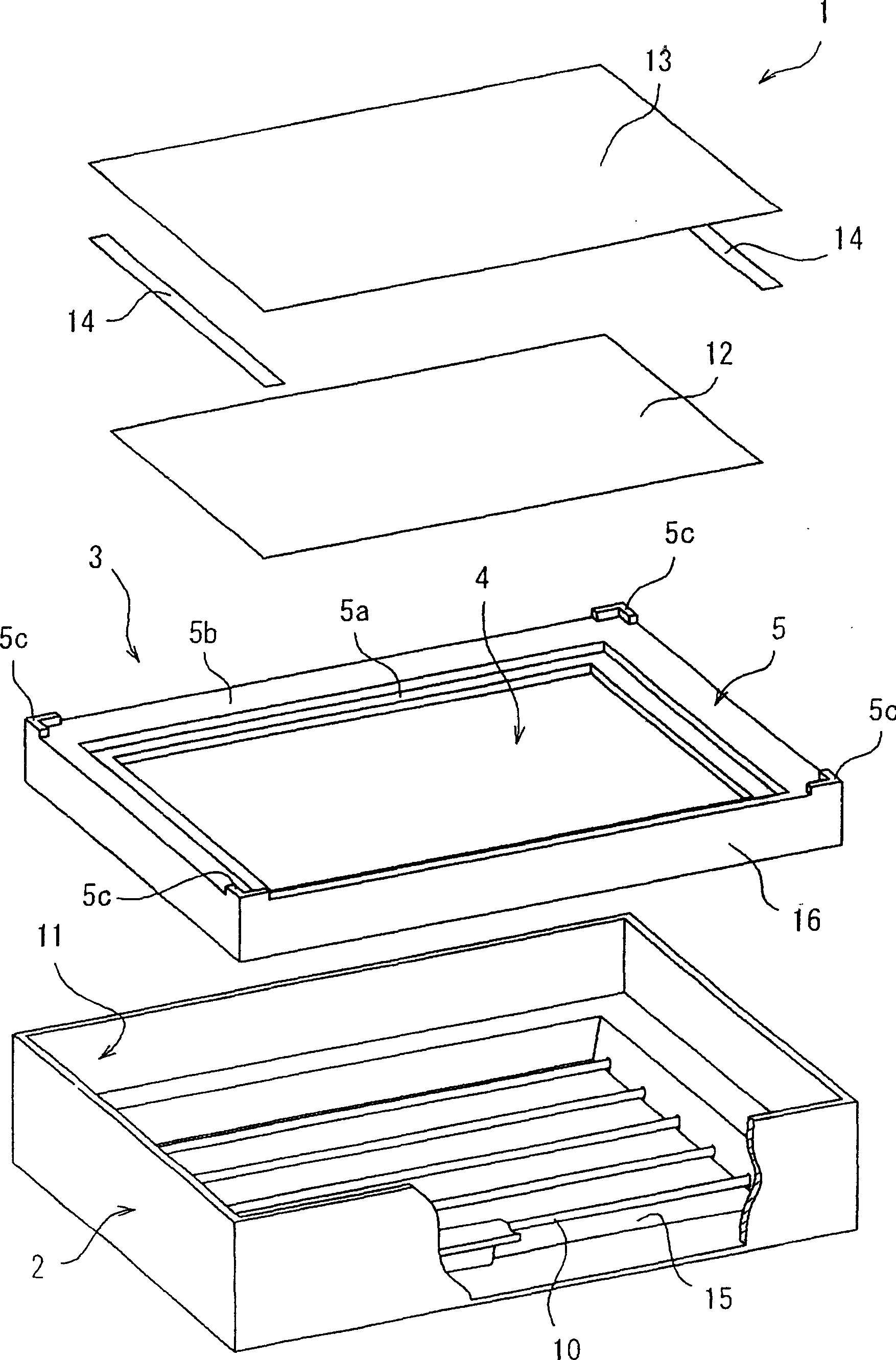

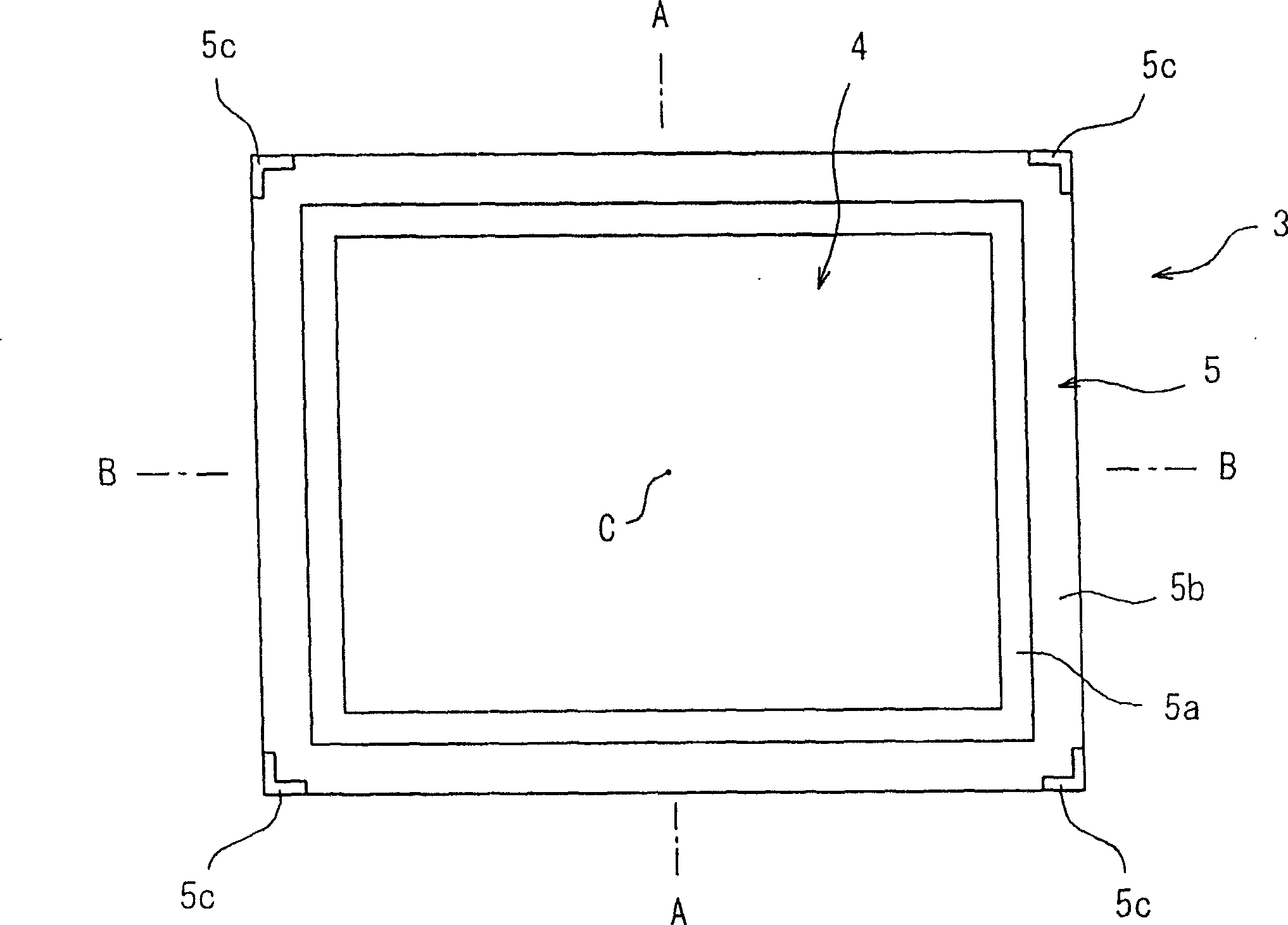

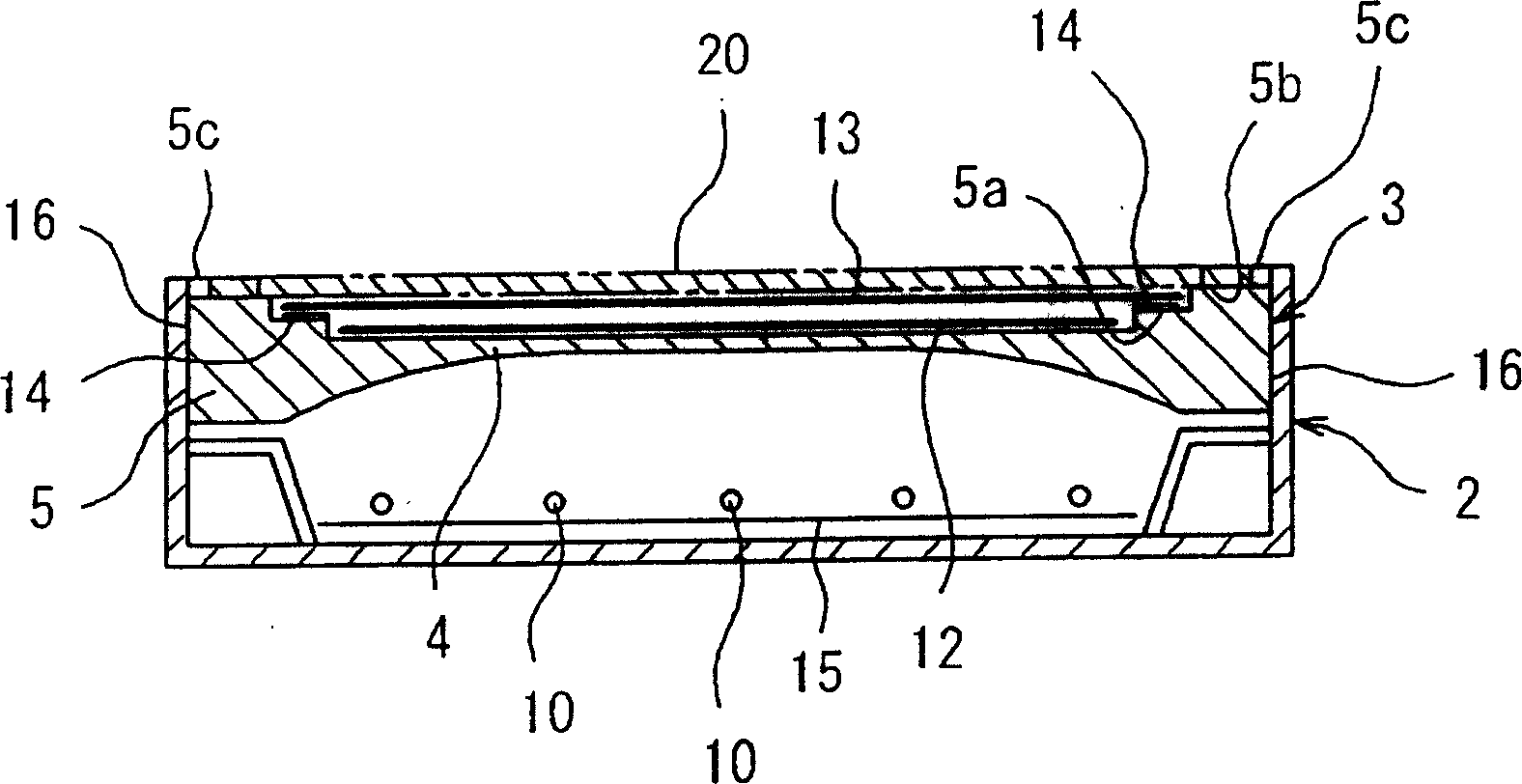

[0044] figure 1 It is a developed perspective schematic diagram showing the schematic structure of the direct type backlight 1 for liquid crystal display devices according to the first embodiment of the present invention, image 3 It is a cross-sectional view (a cross-sectional view perpendicular to the longitudinal direction of the light source 10). The direct type backlight 1 includes a box-shaped lower frame 2 having an opening 11 on the upper side, and a plurality of light sources 10 arranged in parallel to each other inside the lower frame 2 . In addition, the direct type backlight 1 further includes a diffusion plate integrated frame portion 3 disposed on the opening portion 11 of the lower frame 2 to close the aforementioned opening portion 11, and 2 diffuser plate integrated frame portions arranged to overlap each other along the outer surface of the diffuser plate integrated frame portion 3. One optical sheet 12, 13, and a double-sided tape 14 for adhering the optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com