Unitized cage for cylindrical roller bearing

A technology of cylindrical rollers and cages, applied in the field of cages, can solve the problems of expensive manufacturing, lack of strength, and high manufacturing costs, and achieve the effect of simplifying mechanical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

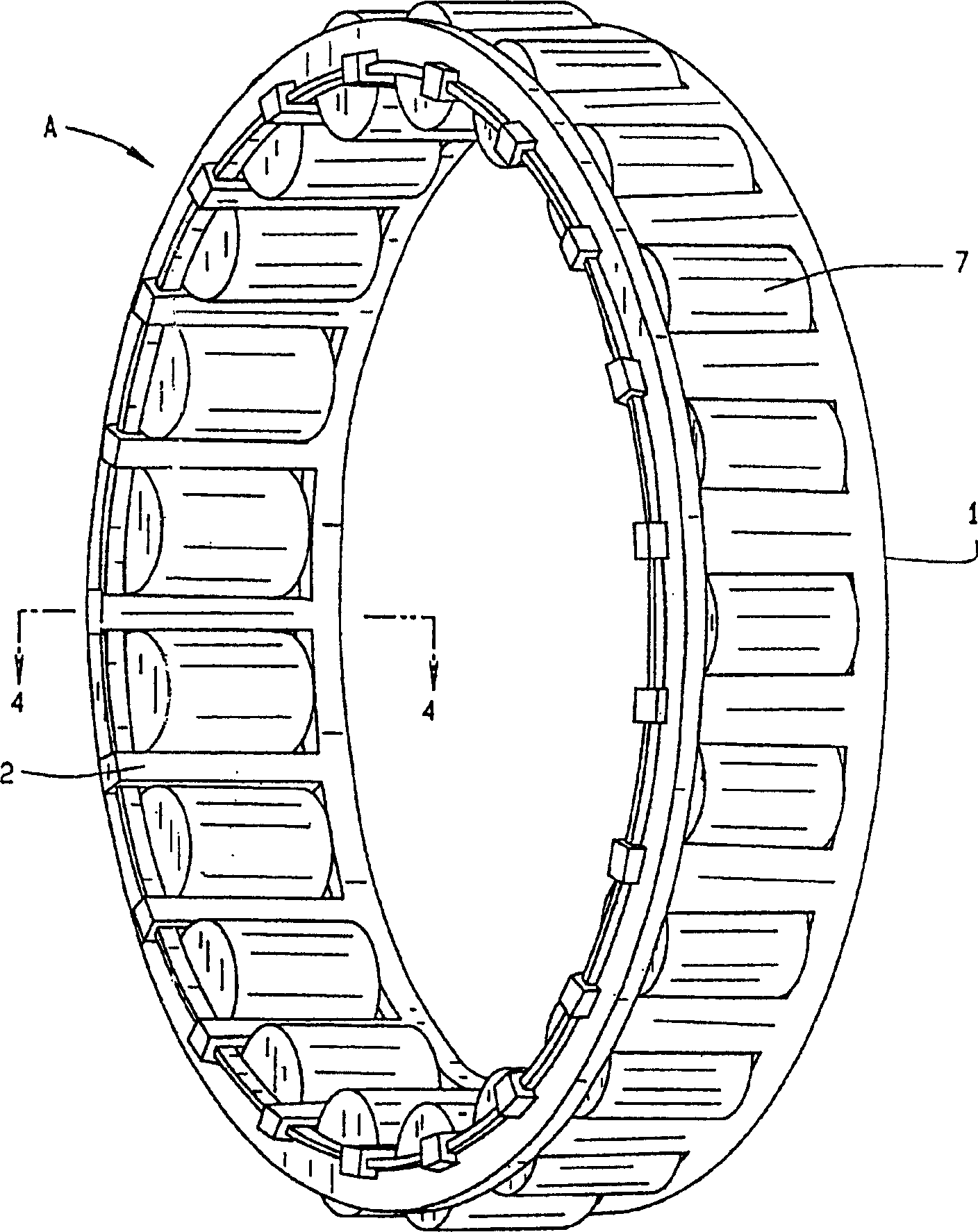

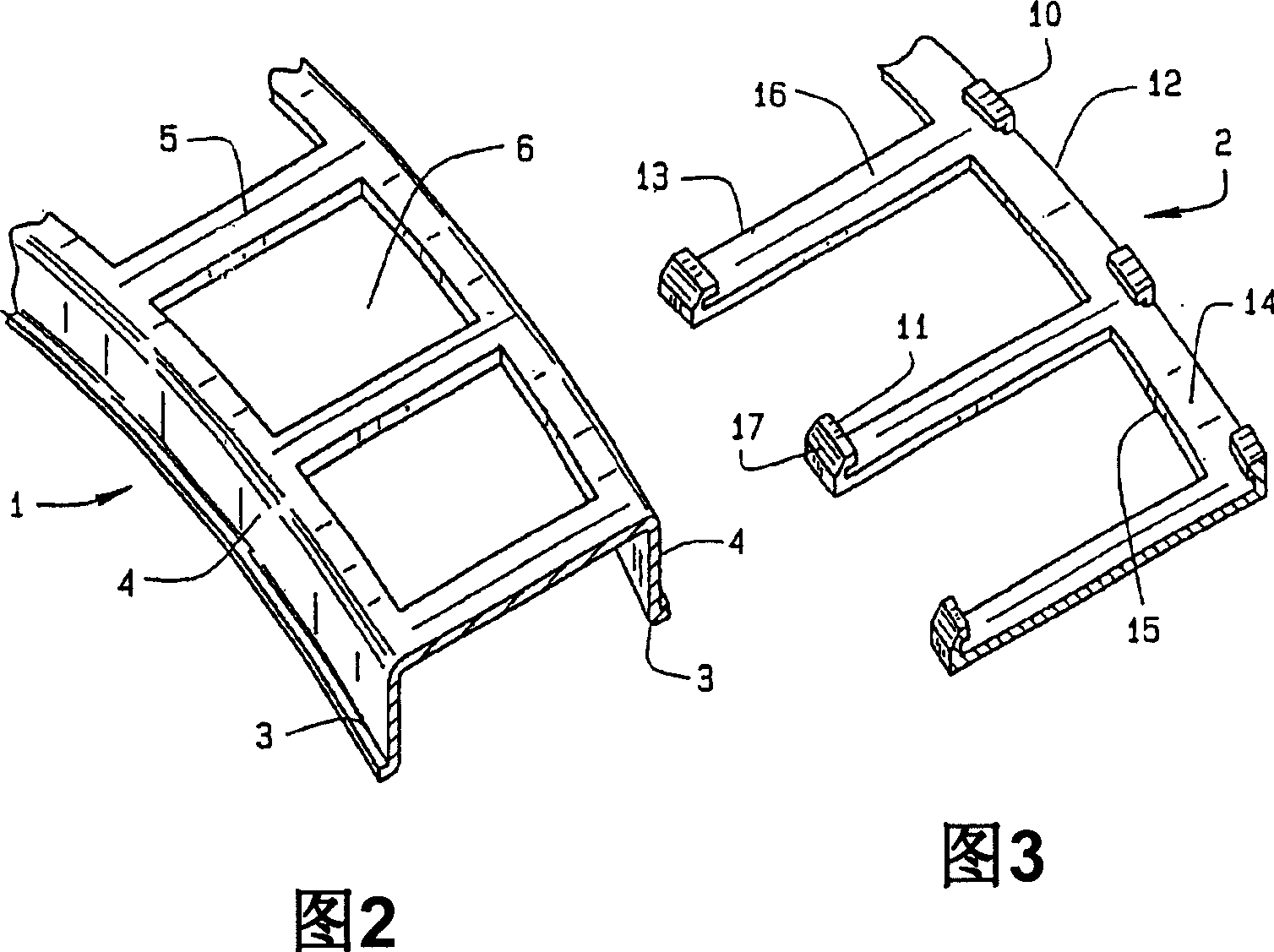

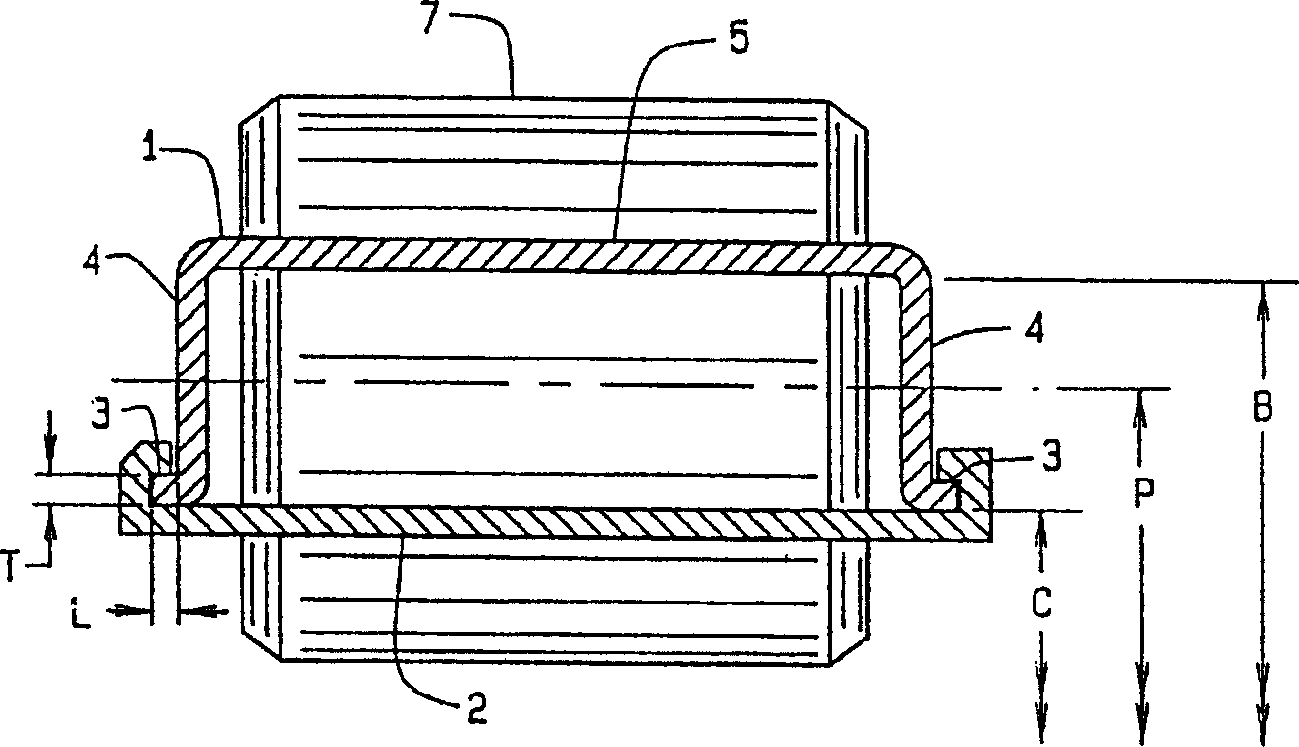

[0019] now refer to figure 1 , showing combined cage A. The composite cage A has a cage sleeve 1 and a cage ring 2 for containing and aligning a plurality of cylindrical rollers 7 . The cage sleeve 1 in FIG. 2 is formed as an annular ring with an X-axis and a generally hat-shaped cross-section. The hat shape is composed of two end face axial protrusions 3 with a length L and a thickness T, two end faces 4 and an upper part 5 . The two end faces 4 extend radially from the axis X and are generally perpendicular to the axial projections 3 of the end faces. In an alternative embodiment, the two end faces are generally not perpendicular to the axial protrusions 3 on the two end faces. The end faces 4 are connected together by an upper part 5 .

[0020] The upper part 5 has a plurality of cage grooves 6 dimensioned and arranged to allow the insertion of a plurality of cylindrical rollers 7 . Such shape and size of the plurality of cage grooves 6 allows free rotation of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com