A Radial Piston Fuel Supply Pump Applied to High Pressure Common Rail Fuel Injection System

A fuel injection system and high-pressure common rail technology, applied in the direction of fuel injection pump, fuel injection device, charging system, etc., can solve the problems of restricting the application of high-pressure fuel pump, lack of superiority, etc., achieving low cost, reduced leakage, and reduced The effect of fatigue wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

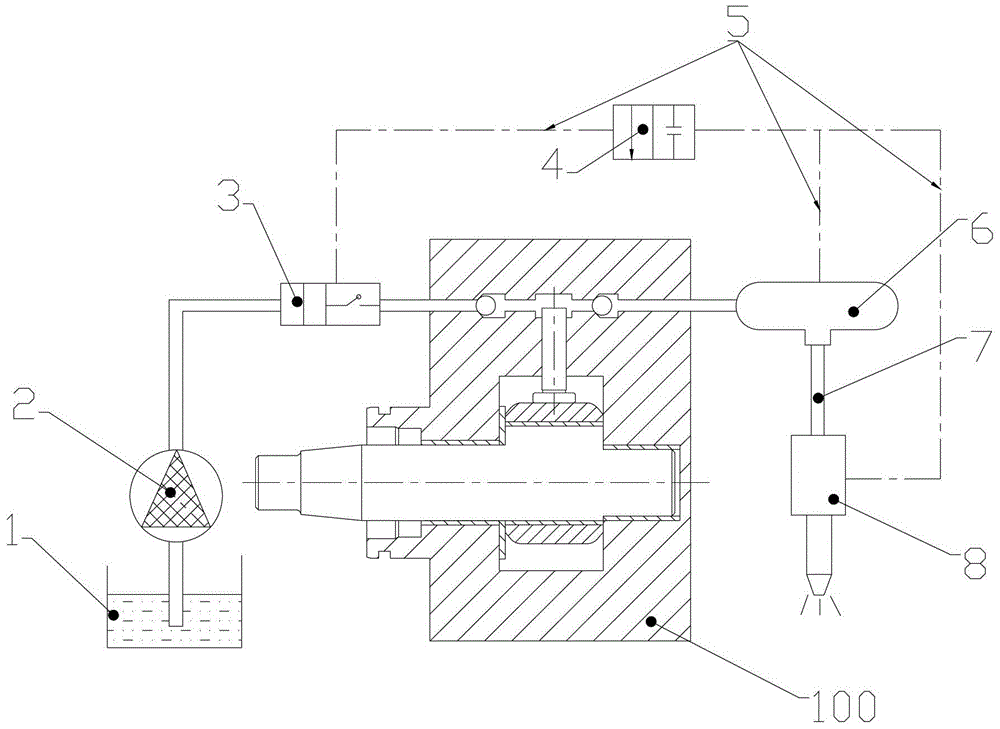

[0049] see figure 1 , the figure is a schematic diagram of the structure of the high-pressure common rail fuel injection system. The system mainly includes: radial plunger oil supply pump 100, common rail pipe 6, fuel injector 8, ECU 4, wiring harness 5 and other components. The working principle of the system is: the fuel delivery pump 2 sucks the fuel from the engine oil tank 1 to the metering valve 3 at a certain pressure through the principle of vacuum adsorption, and the metering valve 3 determines its opening degree through the given control current of the ECU4, thereby controlling the flow of fuel. The size of the amount of oil. The fuel entering the plunger chamber of the radial plunger fuel supply pump 100 is pressurized from the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com