Clutch disengagement bearing

A technology for separating bearings and clutches, applied in clutches, bearings, mechanical drive clutches, etc., can solve the problems of increased wear, friction and rust, and can not achieve the service life of automobile manufacturers, reduce bearing load, ensure high temperature resistance, The effect of improving emergency operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

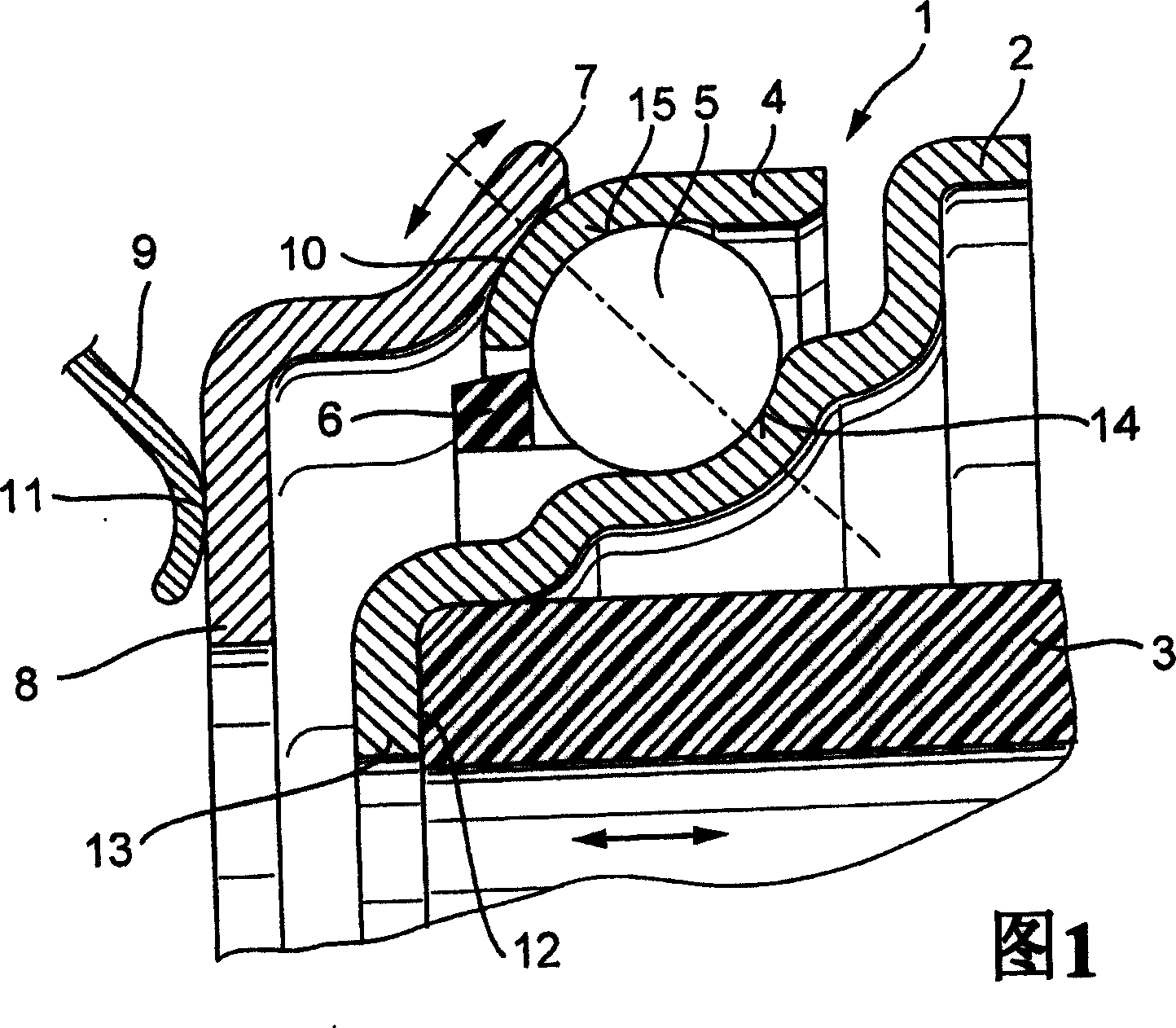

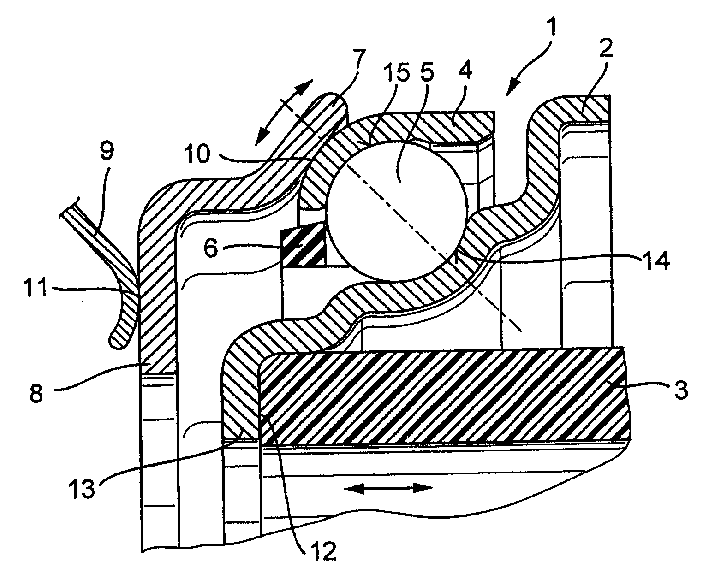

[0031] FIG. 1 shows the release bearing 1 in the mounted state. In this case, the inner bearing ring 2 is connected in a rotationally fixed manner to an actuating device 3 which surrounds a transmission shaft (not shown in FIG. 1 ), which connects the internal combustion engine to the gear transmission. For coupling and decoupling, the handling device 3 is axially movable as indicated by the double arrow. Rolling bodies 5 arranged at a distance in a cage 6 are guided between the inner bearing ring 2 and the associated further outer bearing ring 4 . On the outer side of the outer bearing ring 4, an adjusting ring 7 is mounted, which forms a radially inward ring flange 8, on which a spring element 9, in particular a disk spring, of the transmission clutch is supported with appropriate force. As a result of this arrangement, both the adjustment ring 7 and the outer bearing ring 4 are set in rotation with the transmission separation clutch. In order to compensate coupling shocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com