Unit cell structure comprising composite-gasket for fuel cell stack

A fuel cell stack and unit cell technology, which is applied to fuel cell components, fuel cells, fuel cell grouping, etc., can solve problems such as reducing surface pressure and sealing performance, poor installability, and reducing fuel cell functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

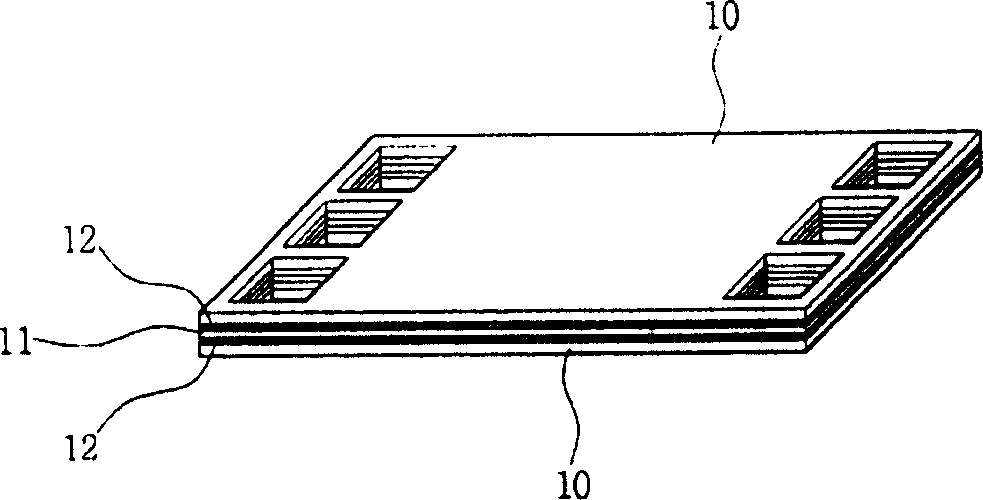

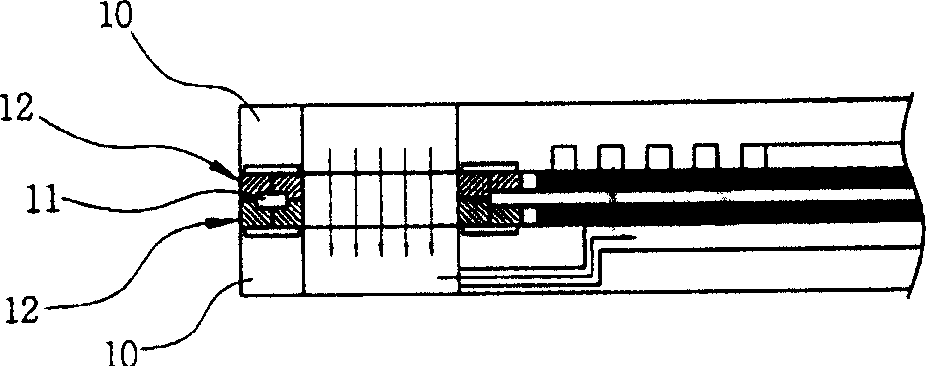

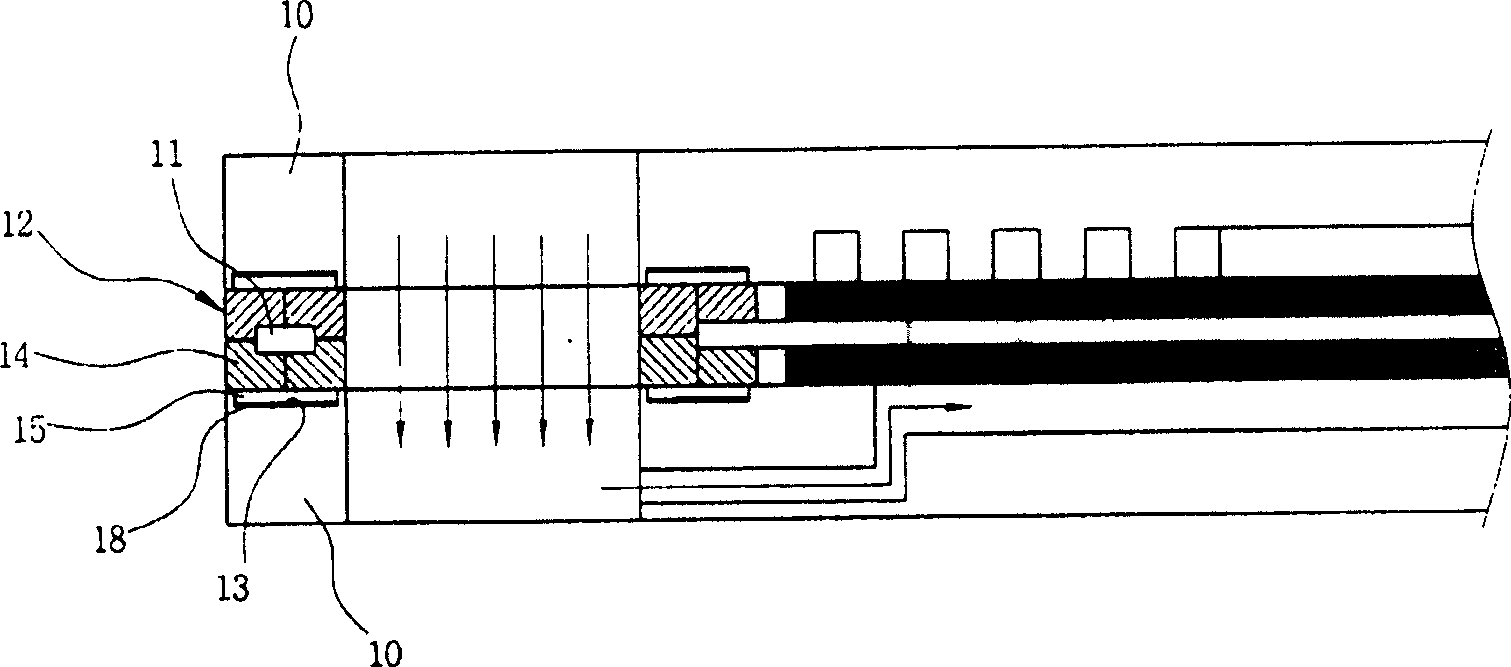

[0024] like Figure 1-3 As shown, in the assembly of separator 10 and MEA 11 together with composite gasket 12 , the boundaries of separator 10 , MEA 11 and gasket 12 are aligned by the two rows of shims 14 of gasket 12 . That is, the separators 10 are disposed on opposite sides of the MEA 11 with the gasket 12 disposed between each separator 10 and the MEA 11 . When the separator 10, the MEA11 and the gasket 12 are assembled into one, the two rows of gaskets 14 of the gasket 12 are finally pressed, and the outer gaskets of the two rows of gaskets 14 reach a position that completely surrounds the MEA11, so that its boundary is in line with the gasket 12. border alignment. This is possible because the position at which the gasket 12 is attached to the partition 10 is determined from the calculation of the amount of deformation of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com