Steel cylinder hand cart

A technology for carts and cylinders, applied in the direction of carts, multi-axle carts, motor vehicles, etc., can solve the problems of disasters, low transportation efficiency, limited number of transportation, etc., and achieve the effect of reducing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The structural features of the present invention and the beneficial effects achieved are further described below in conjunction with the accompanying drawings and embodiments.

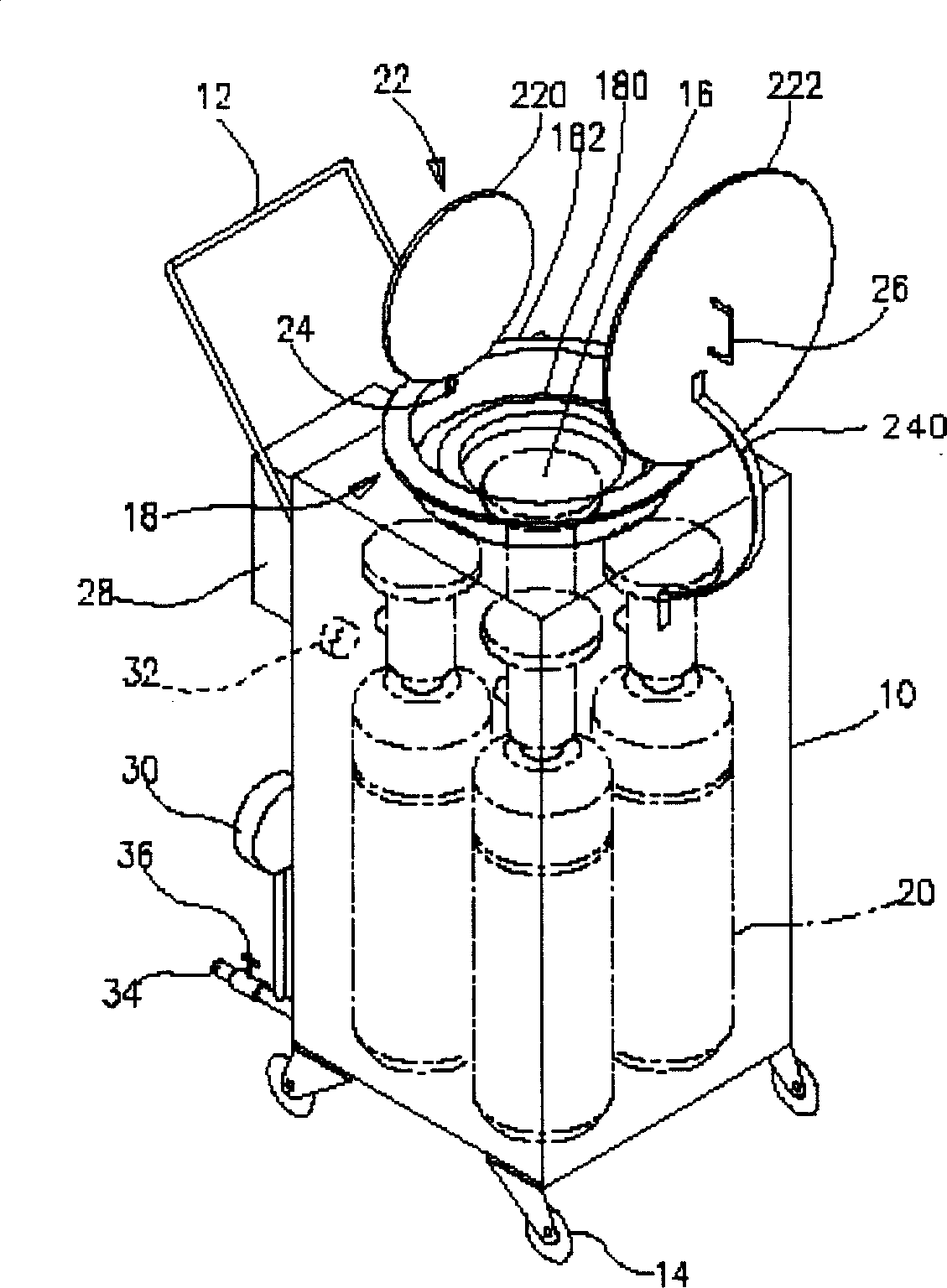

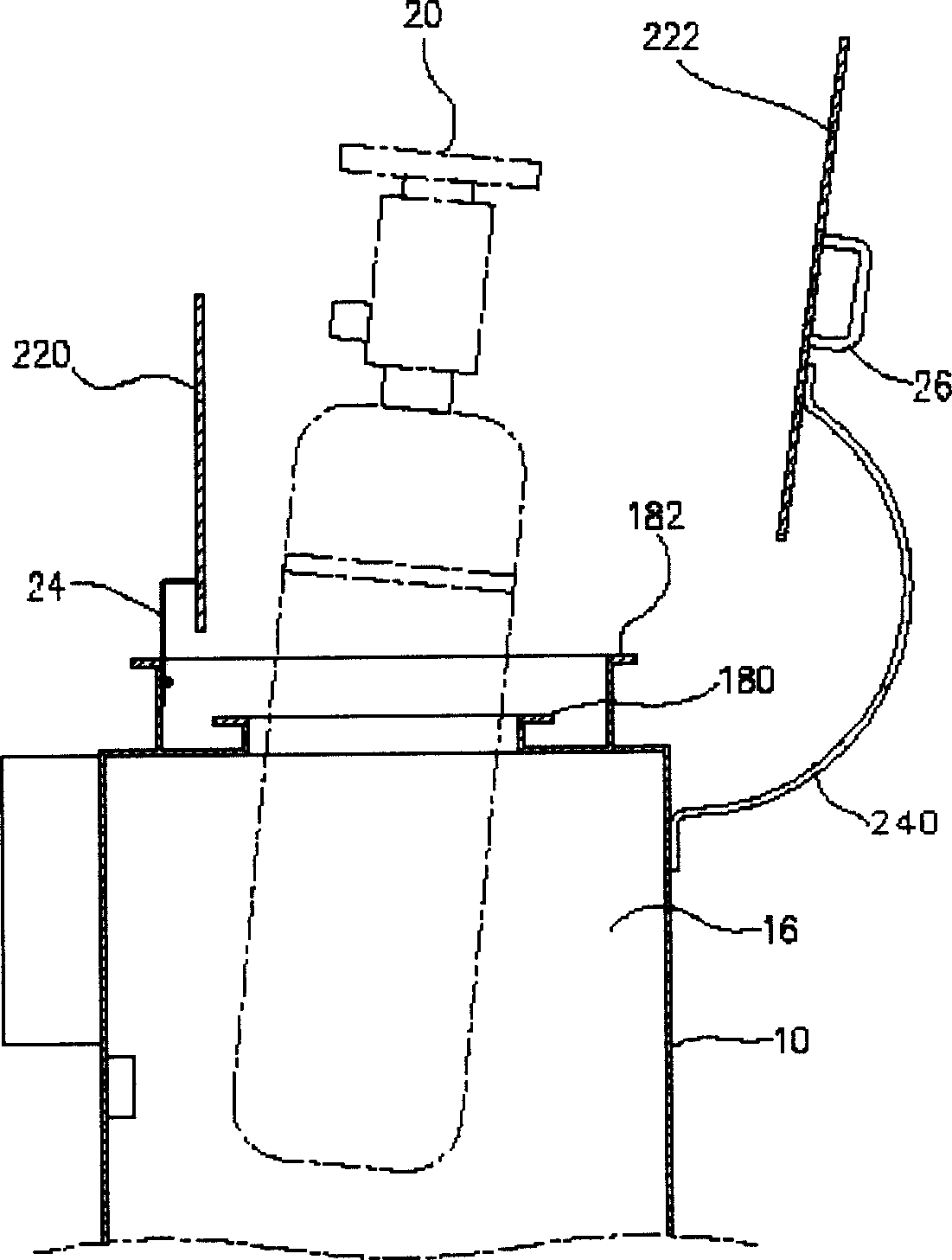

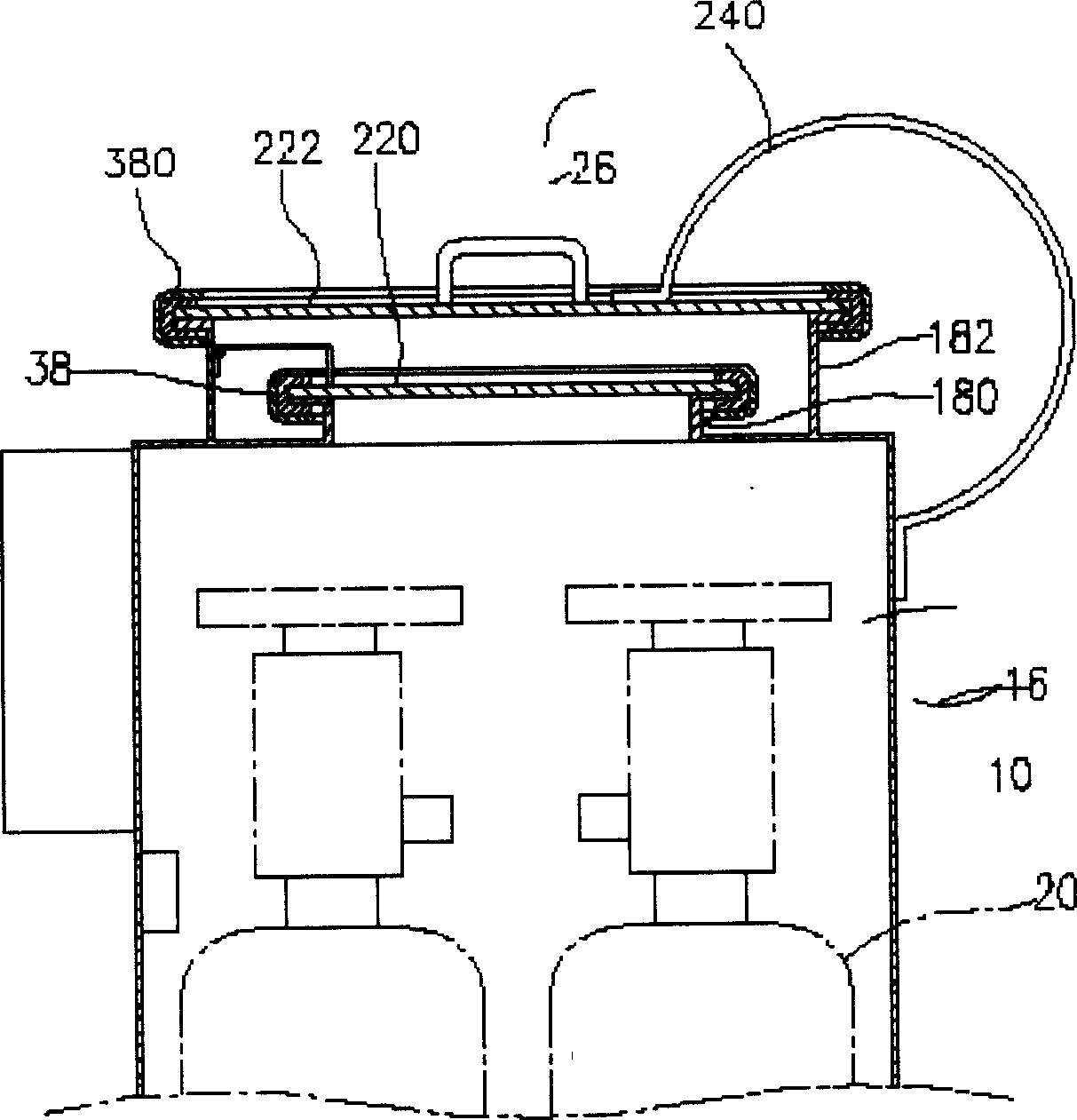

[0045] The present invention is a design of a steel cylinder trolley, and its main function is to enhance the safety of transporting steel cylinders containing dangerous gases. Since most of the gases used in the semiconductor process are toxic, traditional manual transportation or general carts Transportation may be dangerous due to improper operation or human negligence. Therefore, the unique cart design of the present invention can provide airtight protection for the steel cylinders. In case the toxic gas in the steel cylinders leaks, it will not spread into the air and cause Danger.

[0046] First, the schematic diagram of the three-dimensional structure of the present invention is as follows figure 1 As shown, the cylinder trolley mainly includes a trolley main body 10, which is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com