Hardness measurement reagent

A technology of reagents and hardness, applied in the field of reagents for hardness determination, can solve the problems of slow discoloration, etc., and achieve the effect of easy handling and use of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

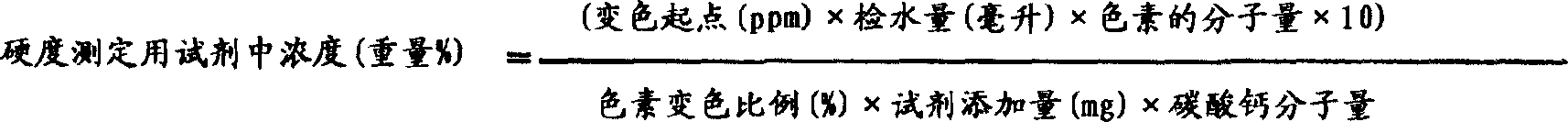

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~3

[0043] Put 50 milliliters of test water into a 100 milliliter beaker, drop 121 microliters of reagents for hardness determination into the test water with a micro-syringe, and shake the beaker gently. The detection water develops color immediately. Observe the shade after 1 minute from the color development. The results are shown in Table 1. In addition, the discoloration start point, discoloration end point and discoloration range of each test area obtained from the results in Table 1 are shown in Table 3. In this test, the hardness equivalent concentration of EBT and EDTA-4Na in the reagent for hardness measurement after dripping each detection water is measured with CaCO 3 In conversion, reagent 1 is 2.2mg / L (EDTA-4Na is 0.7mg / L, EBT is 1.5mg / L), reagent 2 is 3.5mg / L (EDTA-4Na is 1.0mg / L, EBT is 2.5mg / L ), and both reagent 3 and reagent 4 were 2.5 mg / L (EBT was 2.5 mg / L).

[0044] Reagent

[0045] Compounding ingredients

[0046] Reage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com