Inductive magnetic head with non-magnetic seed layer gap structure and method for the fabrication thereof

一种非磁性、磁头的技术,应用在带金属薄板芯的磁头、使用薄膜的磁头、磁记录头等方向,能够解决不利等问题,达到增大面数据存储密度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

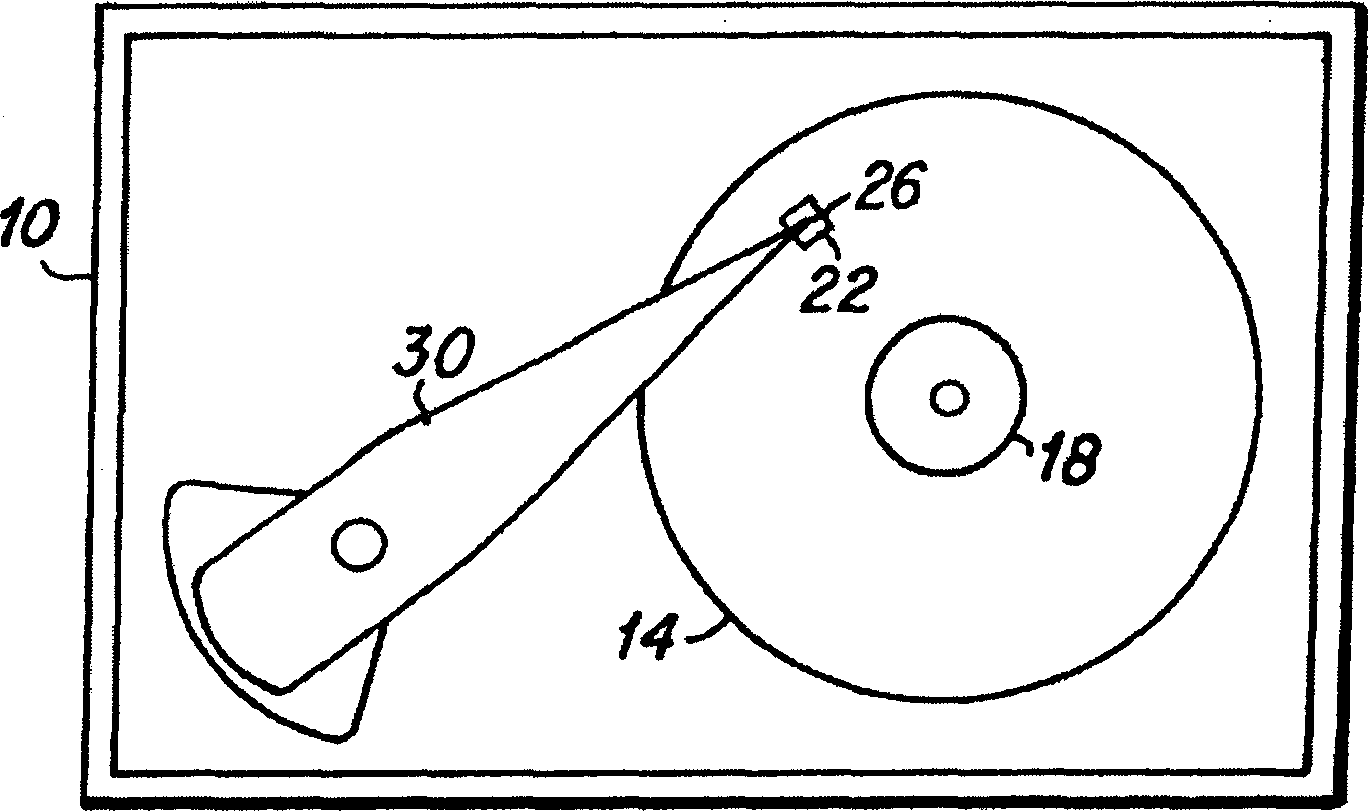

[0020] exist figure 1 A simplified top view of a typical hard disk drive 10 that includes the magnetic head of the present invention is shown in FIG. As shown, at least one hard disk 14 is rotatably mounted on a motorized mandrel 18 . The slider 22 on which the magnetic head 26 is disposed is mounted on the actuator arm 30 to fly over the surface of each rotating hard disk 14, as is known in the art. The present invention includes improved features and methods of manufacture for such a magnetic head, and prior art magnetic heads are described below for a better understanding of the present invention.

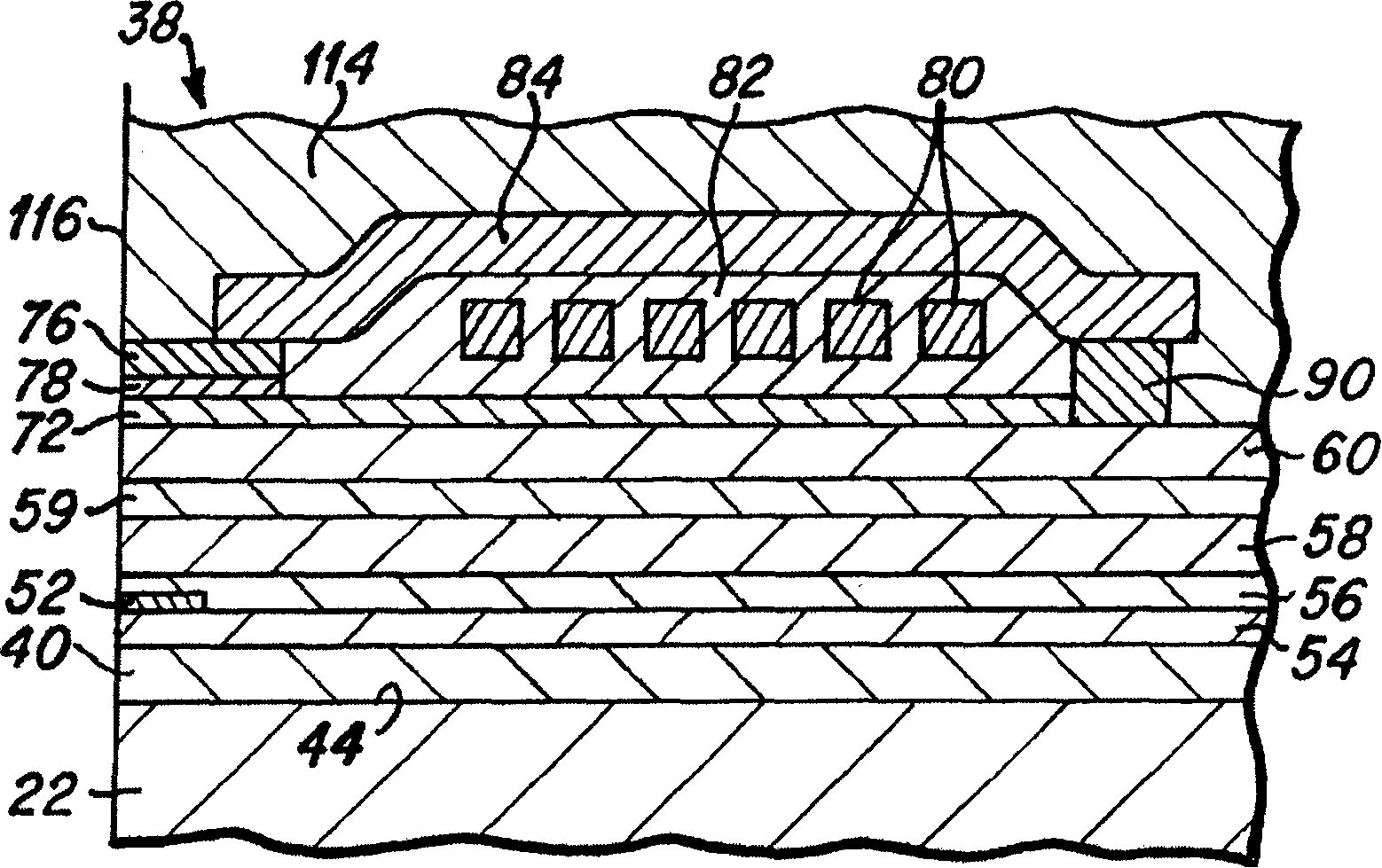

[0021] As understood by those skilled in the art, figure 2 is a side cross-sectional view depicting portions of a prior art magnetic head, which is referred to as a longitudinal head. like figure 2 As shown, the magnetic head 38 includes a first magnetic shield layer ( S1 ) 40 formed on the surface 33 of the slider body material 22 . Readhead sensor element 52 is disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com