Fresnel lens spotlight

A Fresnel lens and spotlight technology, applied in the field of Fresnel lens spotlights, can solve problems such as complex design, and achieve the effects of increasing light quantity and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following detailed description, the same reference numerals refer to the same parts or parts having the same function in different embodiments.

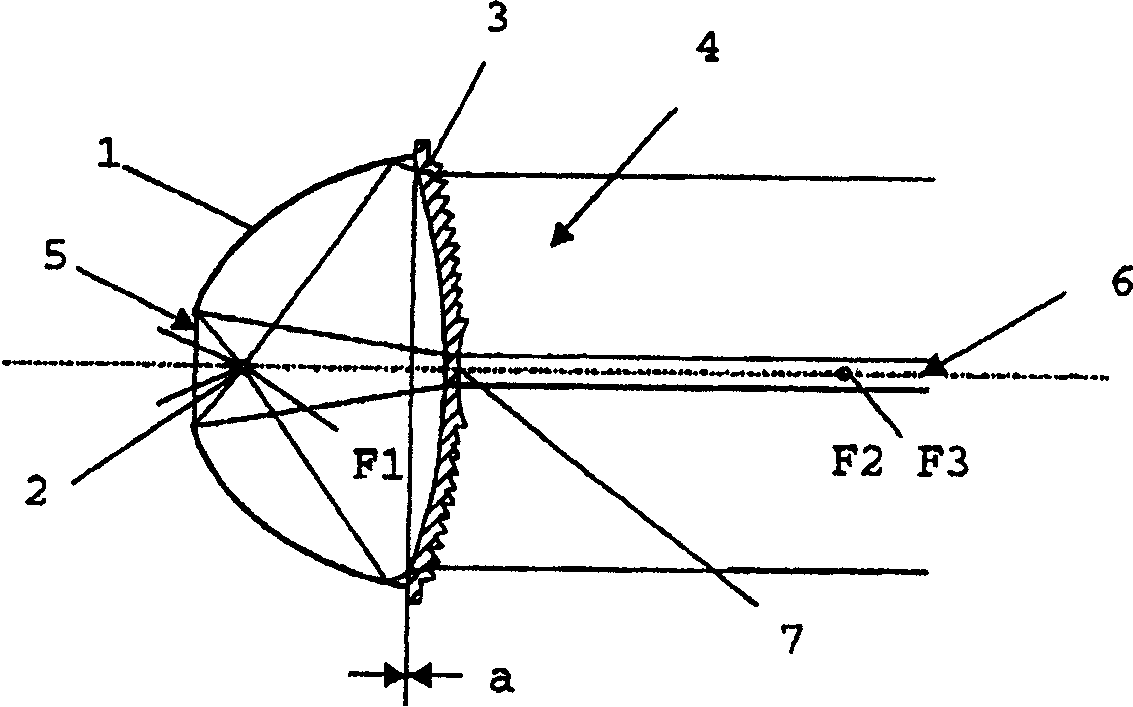

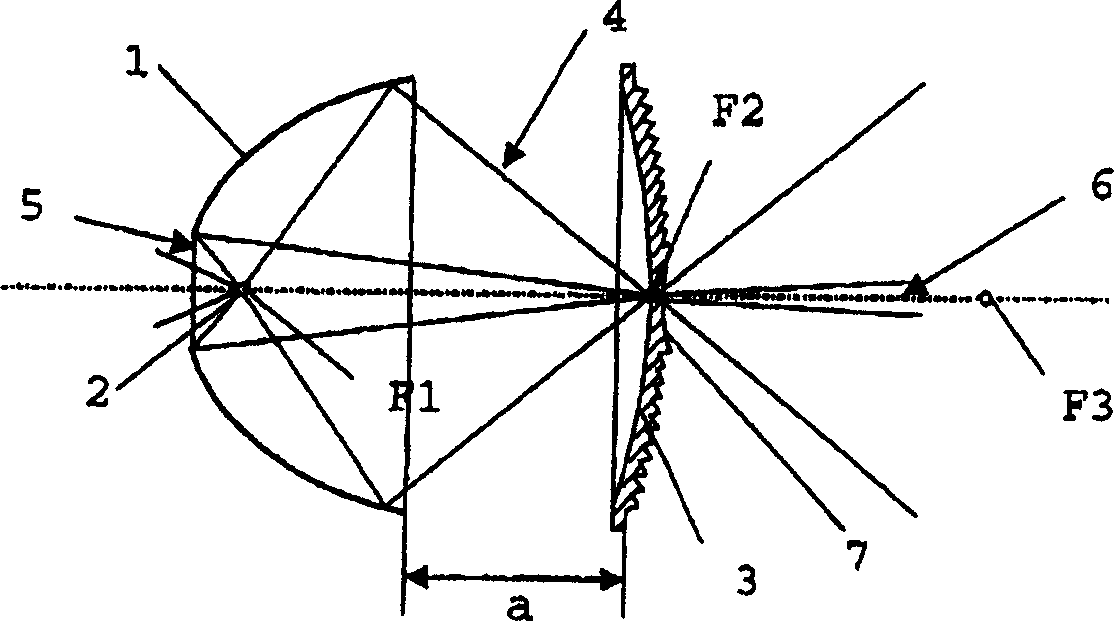

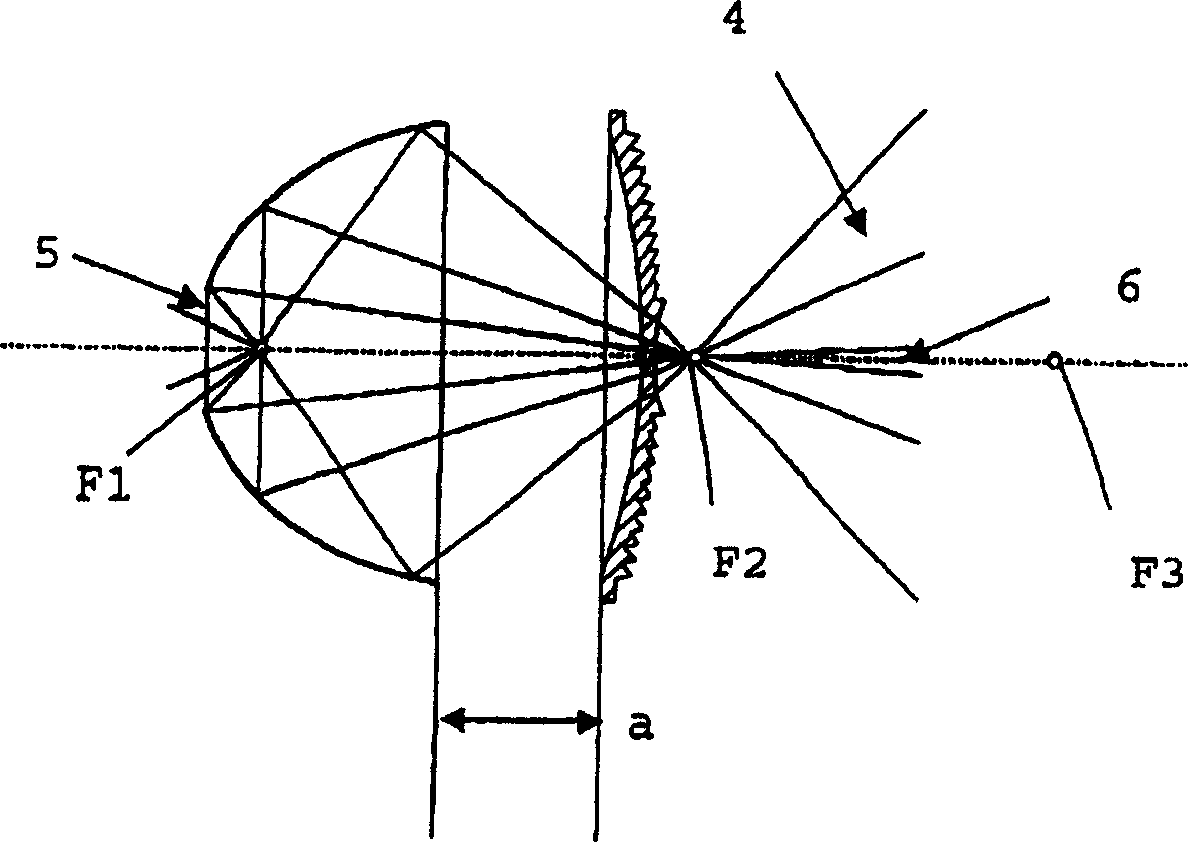

[0043] The following description refers to the appendix figure 1 , which shows an example of a Fresnel lens spotlight at the spot position. The Fresnel lens spotlight basically includes an elliptical reflector 1, a lamp 2 and a Fresnel lens 3, wherein the lamp 2 can be a halogen lamp or a discharge tube, and the Fresnel lens 3 is a lens with negative refractive power, preferably It is a biconcave Fresnel lens.

[0044] exist figure 1 The focal point F2 of the medium elliptical mirror 1 away from the mirror and the virtual or negative focal point F3 of the Fresnel lens 3 approximately coincide on the right-hand side.

[0045] The light 4 emitted by the spotlight is represented schematically in the figure by its outer edge beam.

[0046] The discharge arc of the filament or lamp 2 is placed substantially at the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com