Purifying method for propanol tetrafluoride

A technology of tetrafluoropropanol and a purification method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of the quality decline of discs, the inability to use tetrafluoropropanol as a pharmaceutical intermediate, and the difficulty in achieving high purity. and other problems to achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] Repeat the operation process of Example 1. When the pressure drop reaches 150, do not lower the temperature of the reactor, but instead raise the temperature, and at the same time, intermittently add tetrafluoroethylene monomer for 3 times during the heating process, until the temperature is raised to 140°C, and kept at this temperature for 1 hour . Cool the reaction kettle to room temperature and discharge. The reaction mixture was analyzed for residual initiator levels below the detection limit.

[0048] At room temperature, 80 g of sodium thiosulfate was added to the reaction crude product.

[0049] The reaction mixture was purified and fractionated to obtain tetrafluoropropanol with a purity of more than 99.5%, and the calculated yield was 89.3%.

[0050] During the refining process, the collected tetrafluoropropanol fractions with a purity of more than 99.99% accounted for about 22.7% of the total tetrafluoropropanol collected.

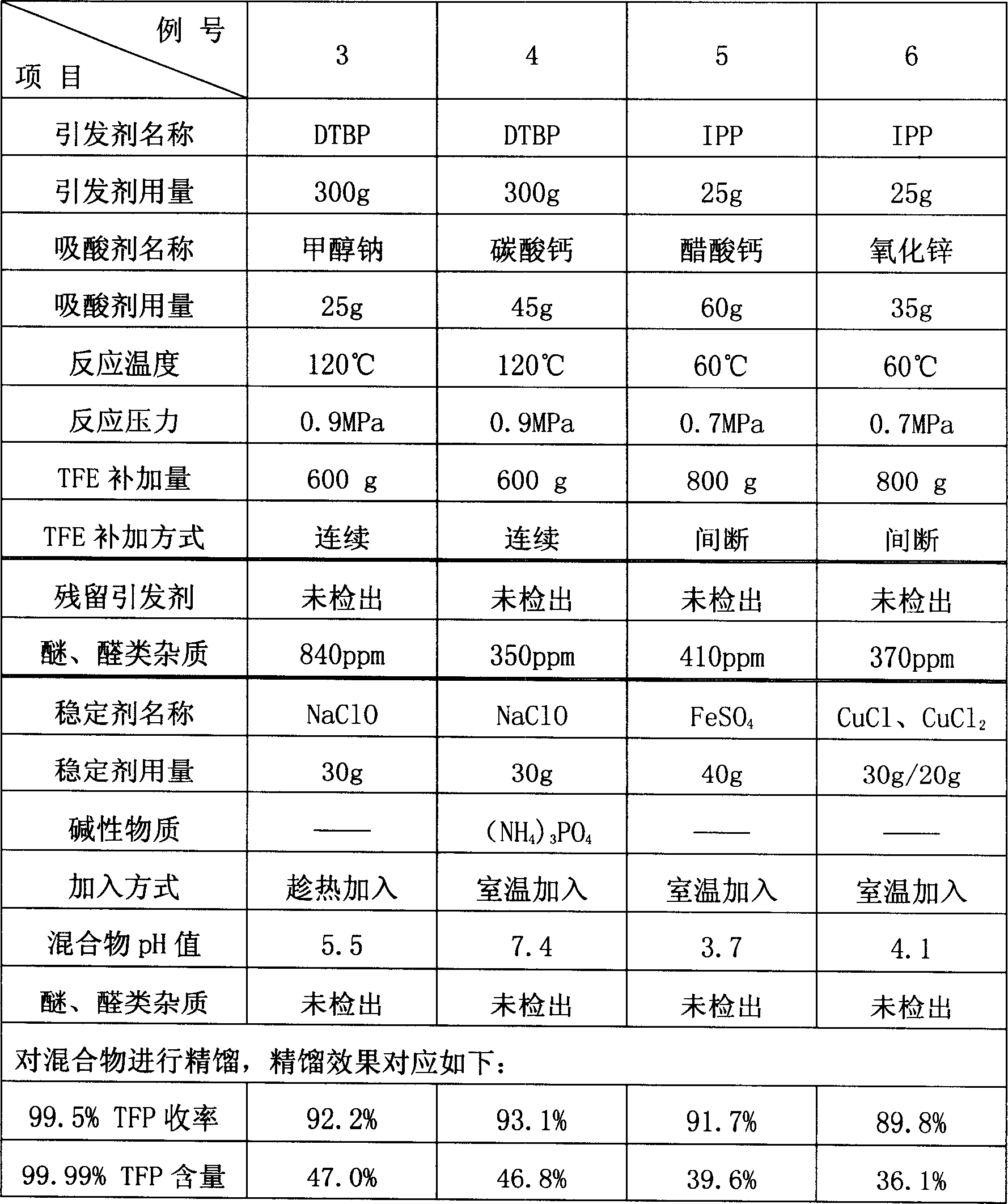

Embodiment 3-6

[0052] Repeat the operation process of Example 2. Only different initiators or acid absorbing agents are used in different embodiments, and different reaction conditions are adopted according to the different initiators used. In the later stage of the reaction, different ways of adding tetrafluoroethylene monomer are adopted, the added amount is different, and the added stabilizer is also different. The specific situation is as follows:

[0053] Table 3-6 List of responses

[0054]

[0055] Note: TFE, TFP, DTBP, and IPP are English abbreviations for tetrafluoroethylene, tetrafluoropropanol, di-tert-butyl peroxide, and diisopropyl peroxydicarbonate, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap