Double action radial plunger pump

A radial column, double-acting technology, applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the problems affecting pump performance, large flow pulsation, impact vibration, etc., to achieve extended life, small flow pulsation, The effect of increasing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

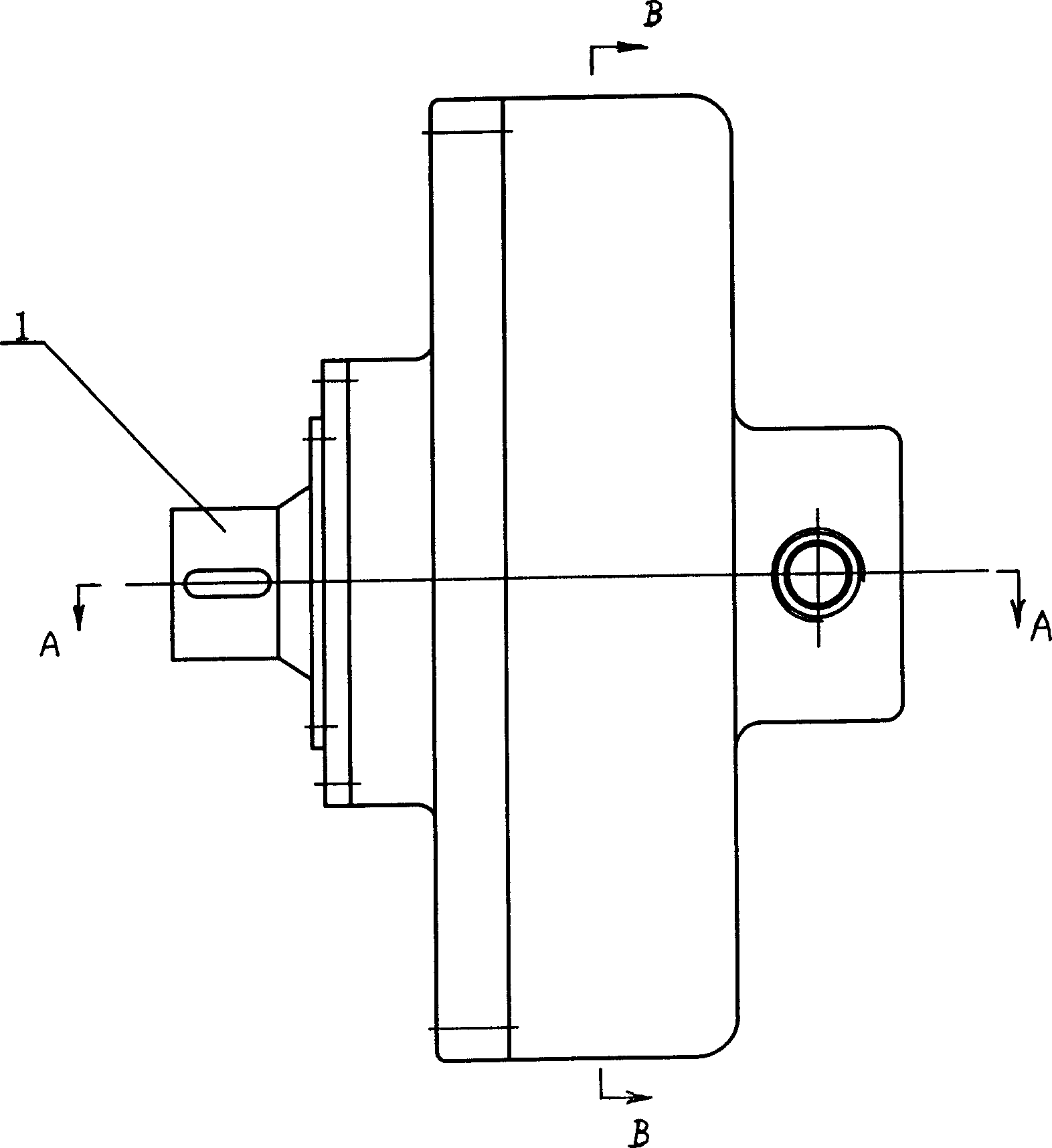

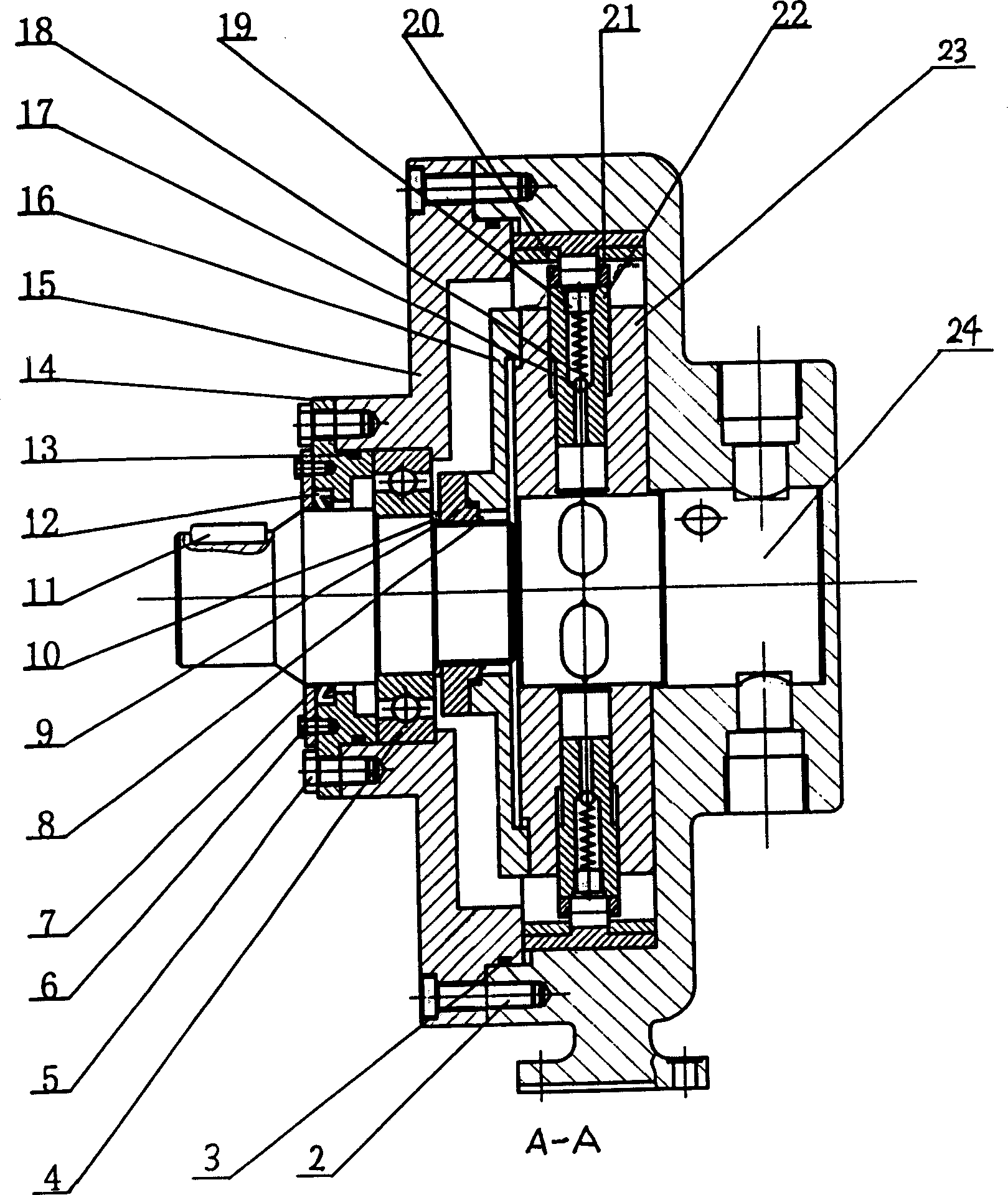

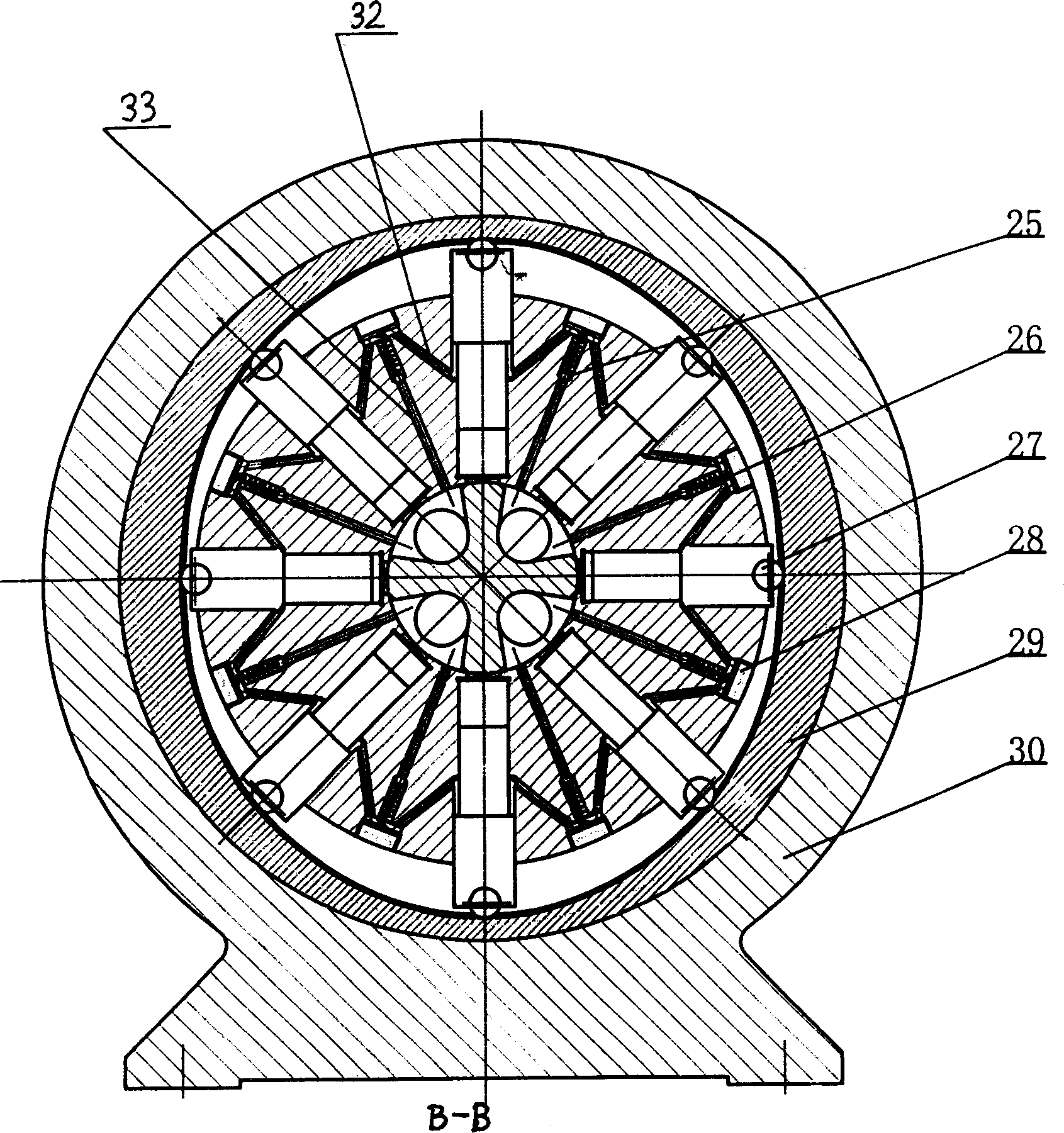

[0017] Such as Figure 1 Shown, transmission shaft (1) and motor (not shown in the figure). Figure 2 is Figure 1 A-A sectional view, the transmission part is composed of a transmission shaft (1), a cross connection turntable (9) and a cross key (16), the transmission shaft (1) drives the distribution shaft (24) to rotate through the cross connection turntable (9), and the transmission shaft ( 1) Drive the rotor (23) to rotate around the distribution shaft (24) through the cross key (16). The outer surface curve of the pressing plate (20) is a circle, and the inner surface curve is an elliptic curve corresponding to the octagonal curve of the stator.

[0018] Such as Figure 2 Shown, the stepped plunger (22) is installed in the plunger hole (31) that offers on the rotor (23). Such as Figure 4a As shown, the stepped plunger (22) is a stepped plunger composed of at least two coaxial cylinders with unequal outer diameters. Such as Figure 2 As shown, the shape of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com