Burner for stove and accessory

A technology of burners and stoves, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., and can solve problems such as deterioration of combustibility, too narrow intervals, interference of flames, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

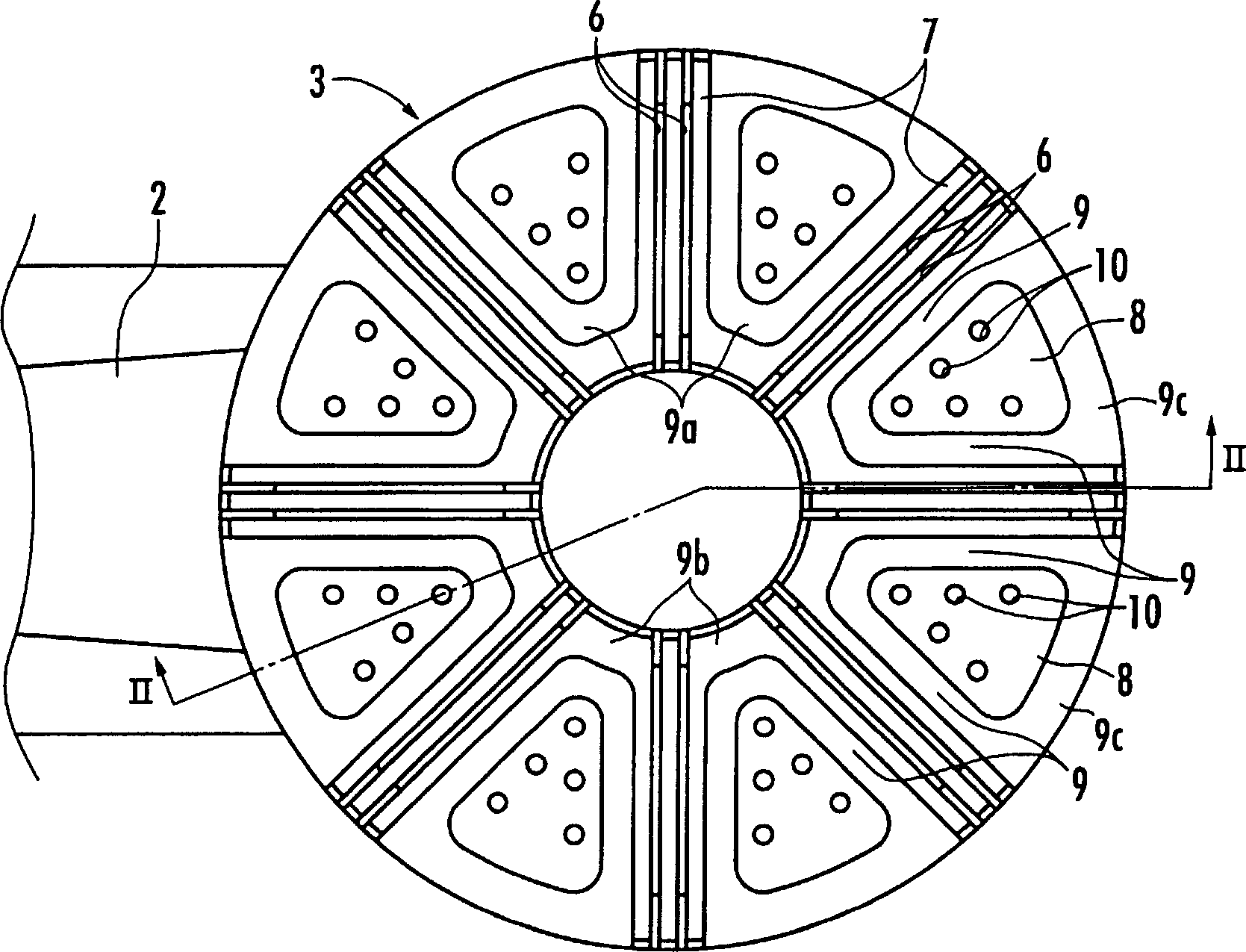

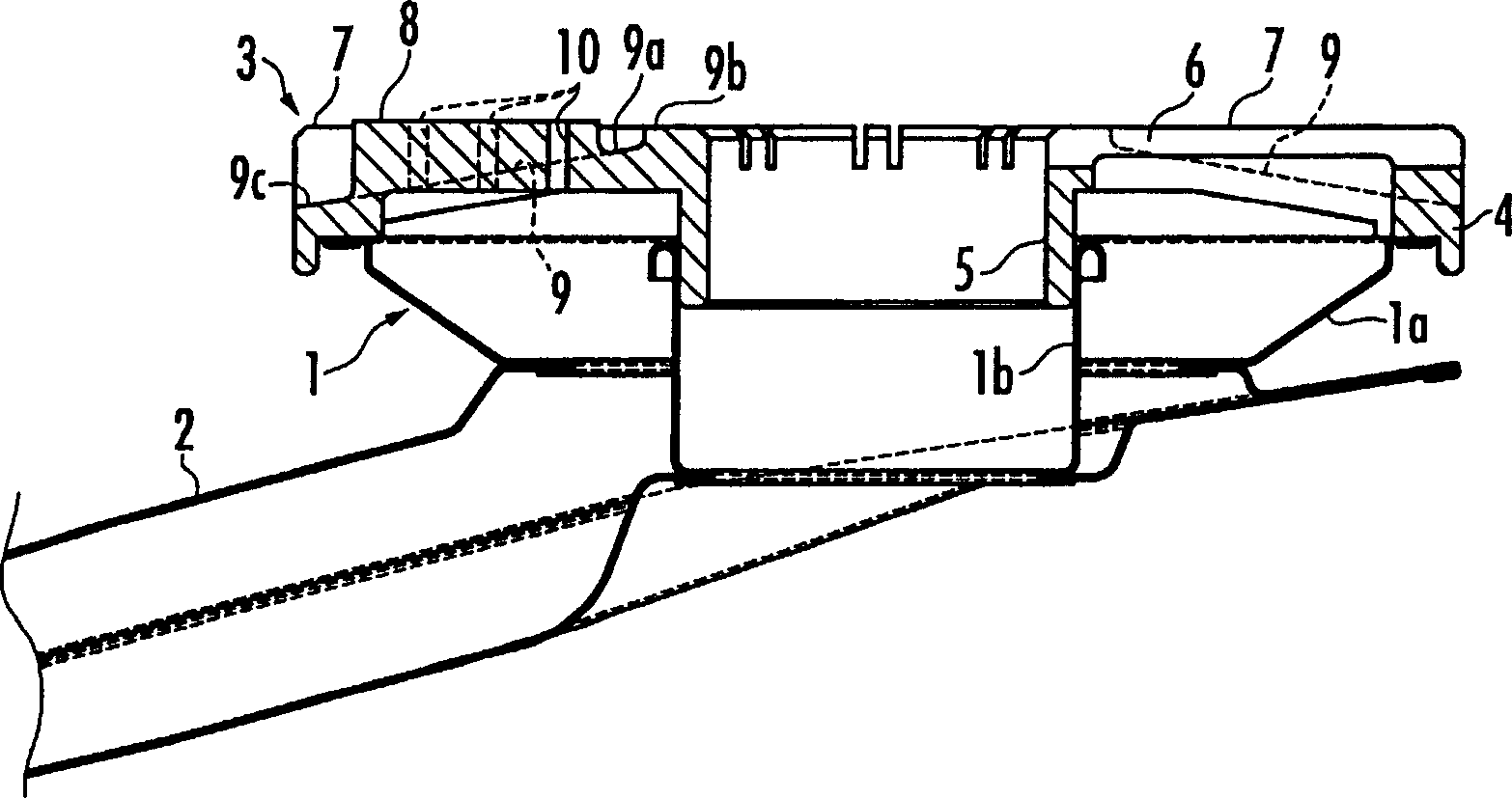

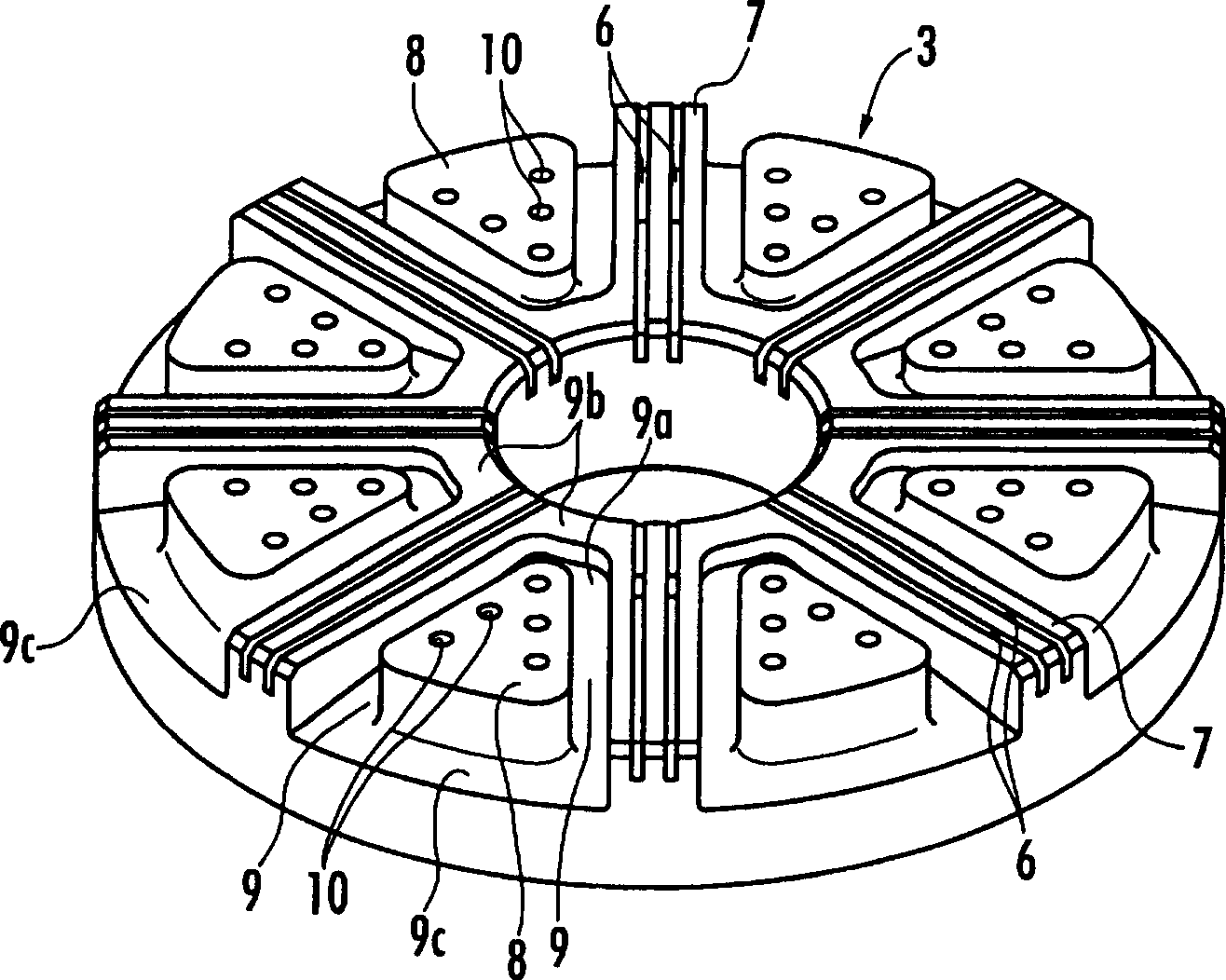

[0015] refer to figure 1 and figure 2 , 1 denotes a burner body of a burner for a stove, and the burner body 1 is formed in an upwardly open ring shape by a disk-shaped outer member 1a and a cylindrical inner member 1b. A mixture of gas and primary air is supplied to the burner body 1 via a mixing tube 2 connected to the burner body 1 . In addition, although the burner body 1 and the mixing tube 2 are made of thin metal plates, the burner body 1 and the mixing tube 2 may be integrally formed by casting.

[0016] On the burner body 1 , an annular burner head 3 covering the burner body 1 from above is detachably mounted. The burner head 3 is a cast product, and has an outer peripheral seating portion 4 seated on the upper edge of the outer member 1a of the burner body 1, and a cylindrical portion embedded in the inner periphery of the inner member 1b of the burner body 1. 5. In addition, although not shown, a ring-shaped juice receiving pan with an inner diameter smaller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com