High-diffraction efficiency quartz transmission grating of 1053 nano wavelength

A diffraction efficiency, transmission grating technology, applied in the field of gratings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

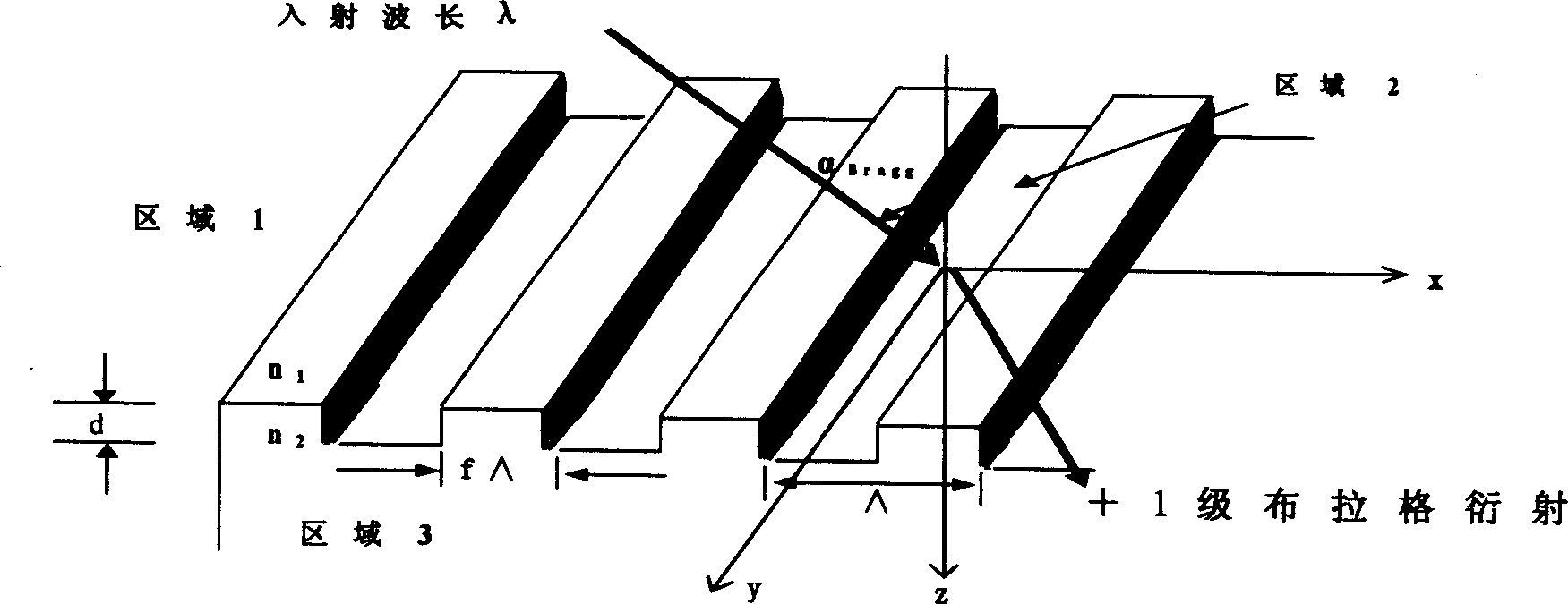

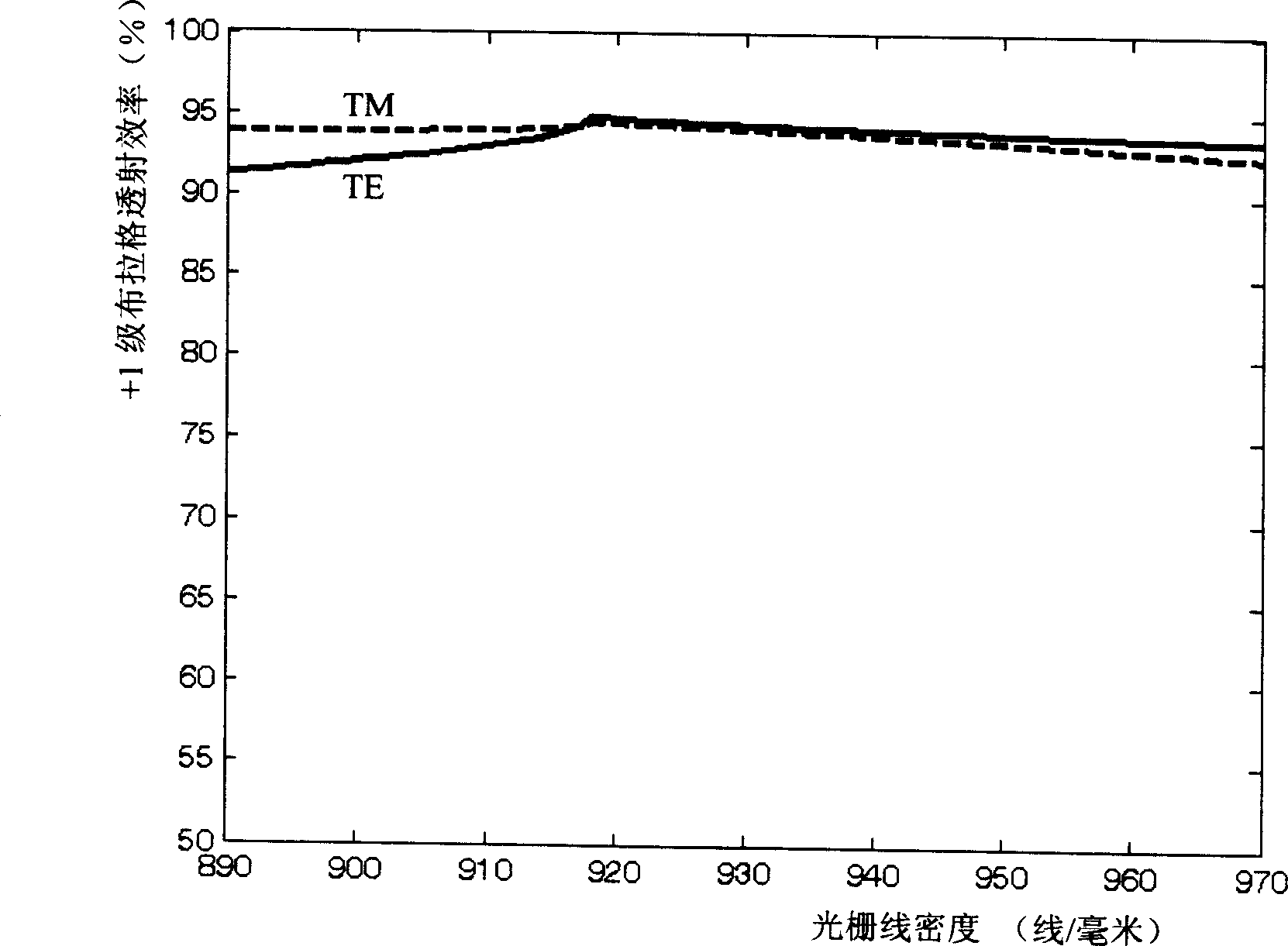

[0017] see first figure 1 , figure 2 with image 3 , the high diffraction efficiency quartz transmission grating of 1053 nm wavelength of the present invention is a high-density rectangular grating, characterized in that the line density of the grating is 895-965 lines / mm, the depth of the grating is 1.9-2.1 microns, and the duty ratio of the grating is for 1 / 2.

[0018] The line density of the grating is 920 lines / mm, and the depth of the grating is 2 microns.

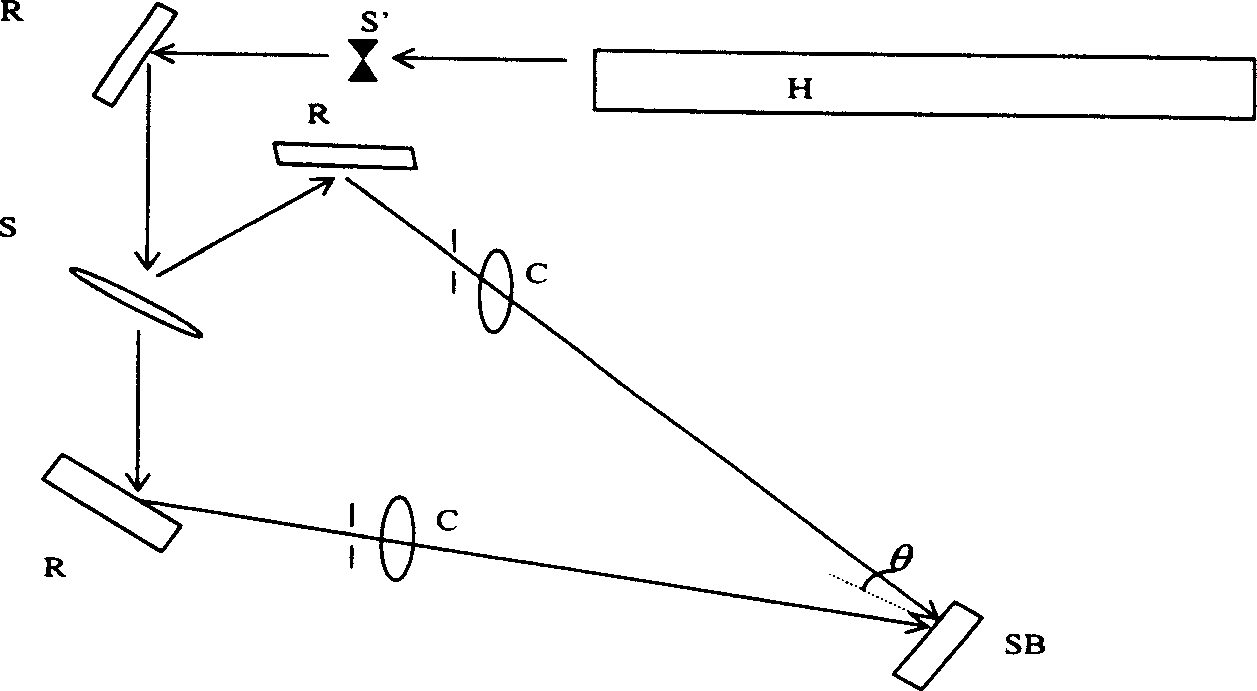

[0019] The grating of the present invention is a high-density rectangular grating manufactured by micro-optical technology. image 3 The shown device records the grating in holographic recording mode: He-Cd laser (wavelength 0.441 μm) emits two beams of plane waves to form an interference field on the substrate at an angle of 2θ. We use a glass plate coated with MICROPOSIT series 1818 photoresist as the recording substrate, ∧ represents the spatial period of the grating, that is, the distance between adjacent str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com