Body of robot for automatic polling high-tension transmission line

A technology of high-voltage transmission lines and robot body, applied in the field of robots, can solve the problems of high risk, hidden danger, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

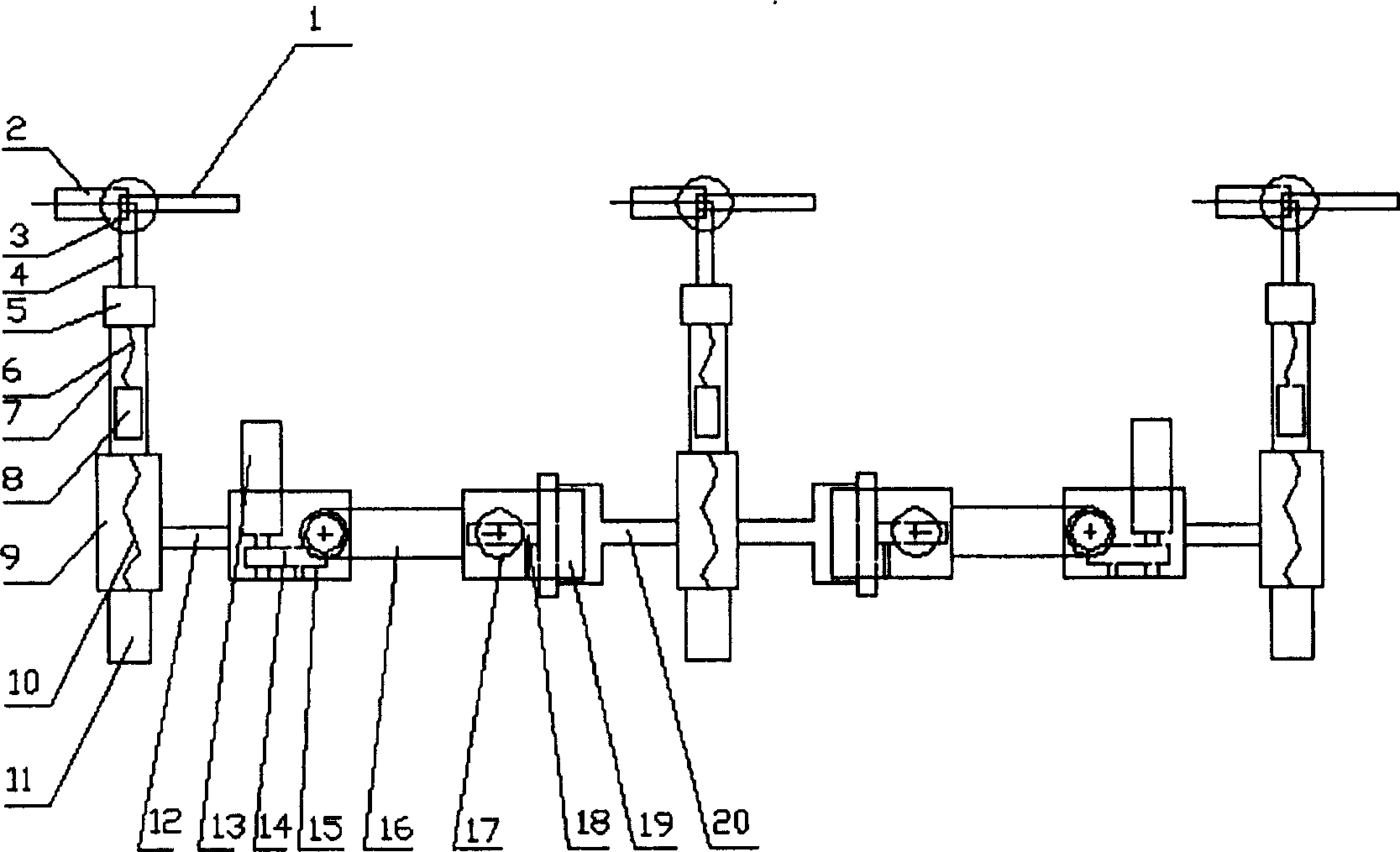

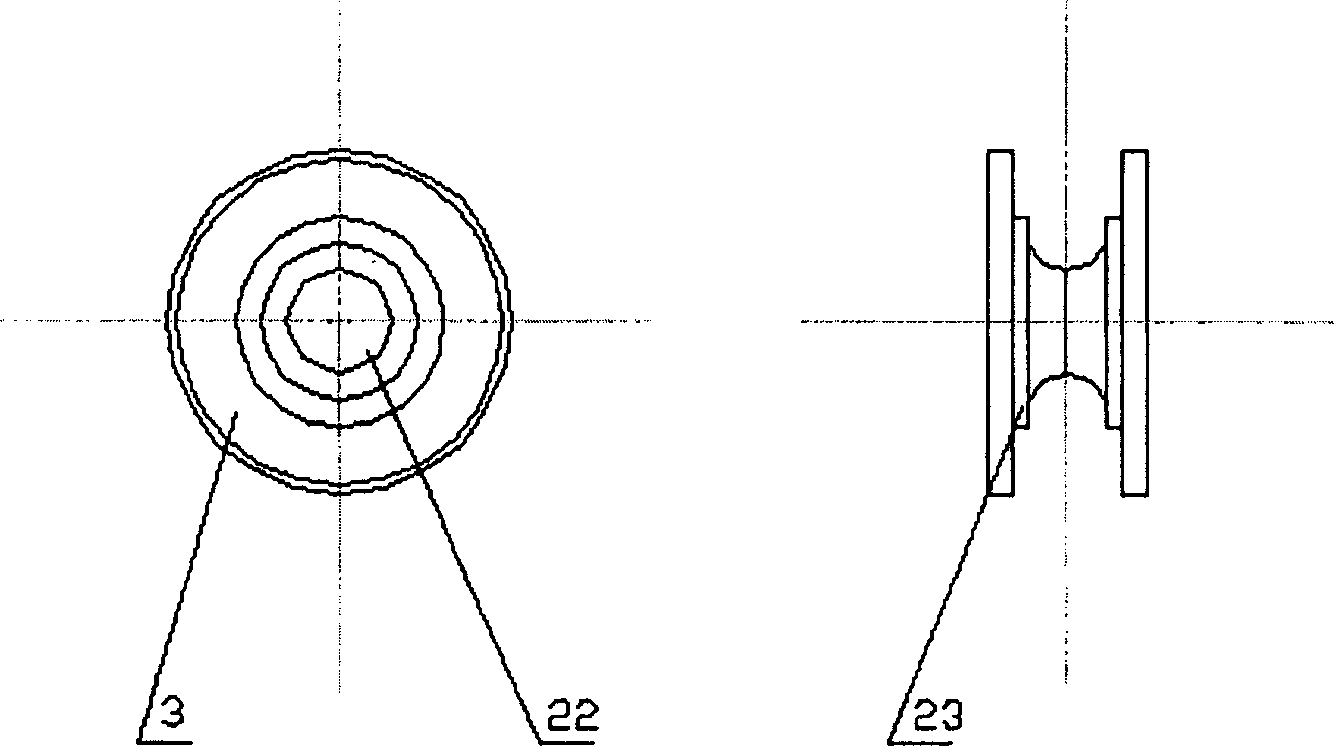

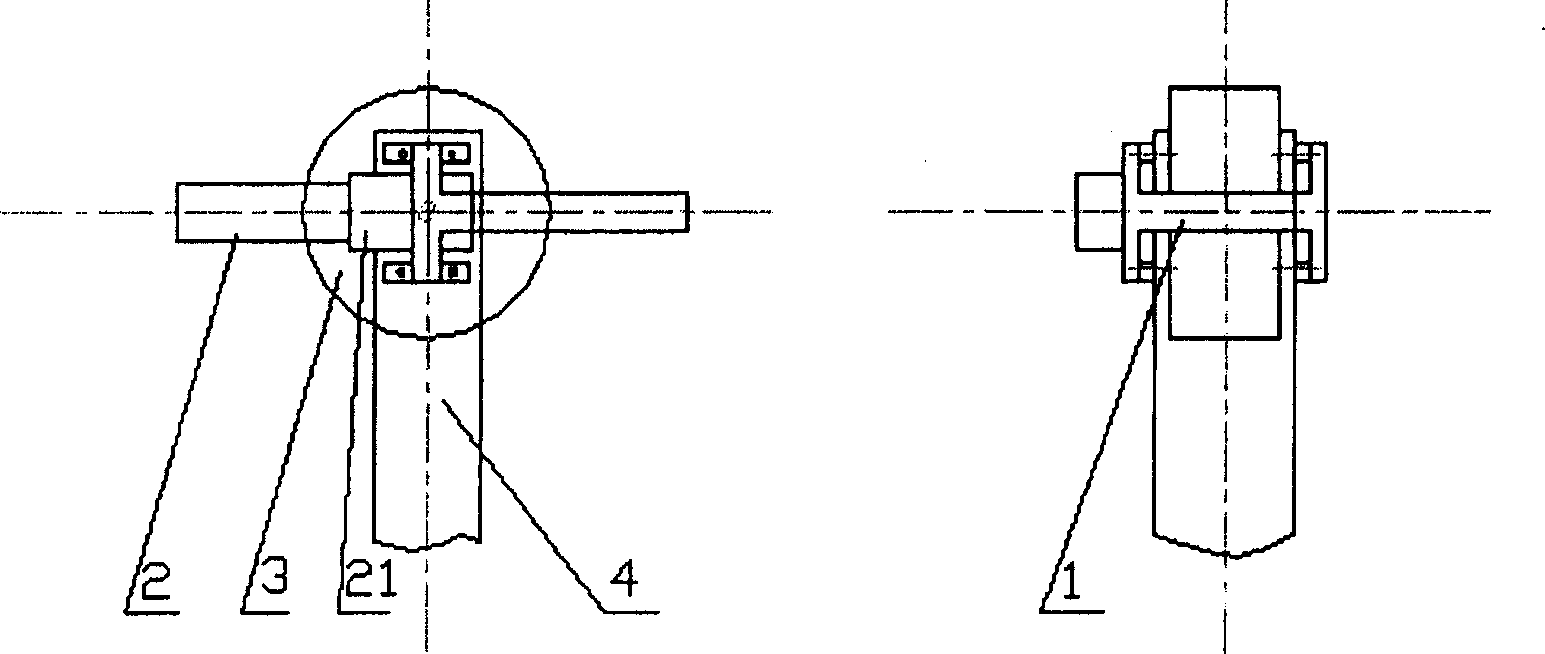

[0020] See first figure 1 , The utility model 110kv transmission line automatic inspection robot body 100 is composed of three robot units 101, 102, 103 and four connecting joints 104a, 104b, 105a, 105b. The three robot units 101, 102 and 103 have the same structure and are connected to each other through four connecting joints 104a, 104b, 105a and 105b. Robot monomers 101, 102 and 103 are composed of drive motor and reducer 2, drive wheel 3, opening and closing motor and reducer 8, opening and closing screw nut, lifting motor and reducer 11, lifting screw 10, wire holding brake 1 and support 4 composition. Wherein, the upper end of the bracket 4 extends vertically along the axis and is connected with a drive motor and a reducer support 21 , and the drive motor and reducer support 21 are fixedly equipped with the drive motor and the reducer 2 . At the joint between the support 4 and the drive wheel 3, the wire brake 1 is horizontally in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com