Plant sheet, process for producing the same and greening method using the plant sheet

A manufacturing method and a construction method technology are applied in the field of greening construction using thin layers of plants to achieve the effects of good growth and cost savings in handling and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The manufacturing method of the plant sheet and the greening construction method using the plant sheet according to the first embodiment will be described.

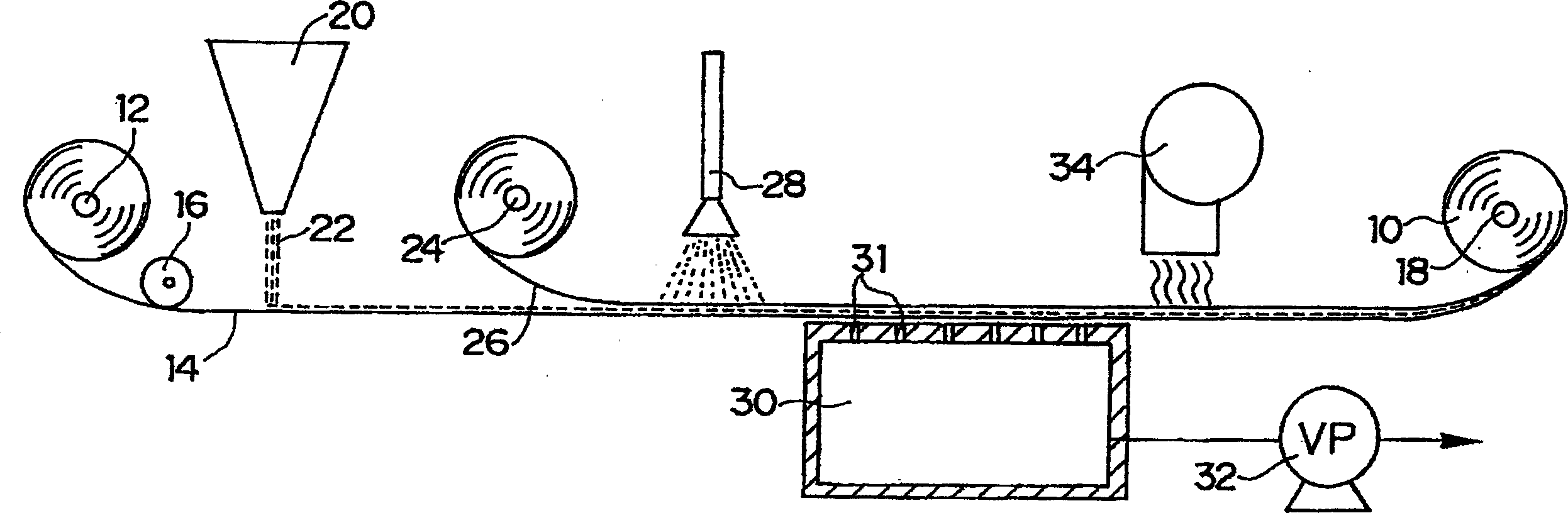

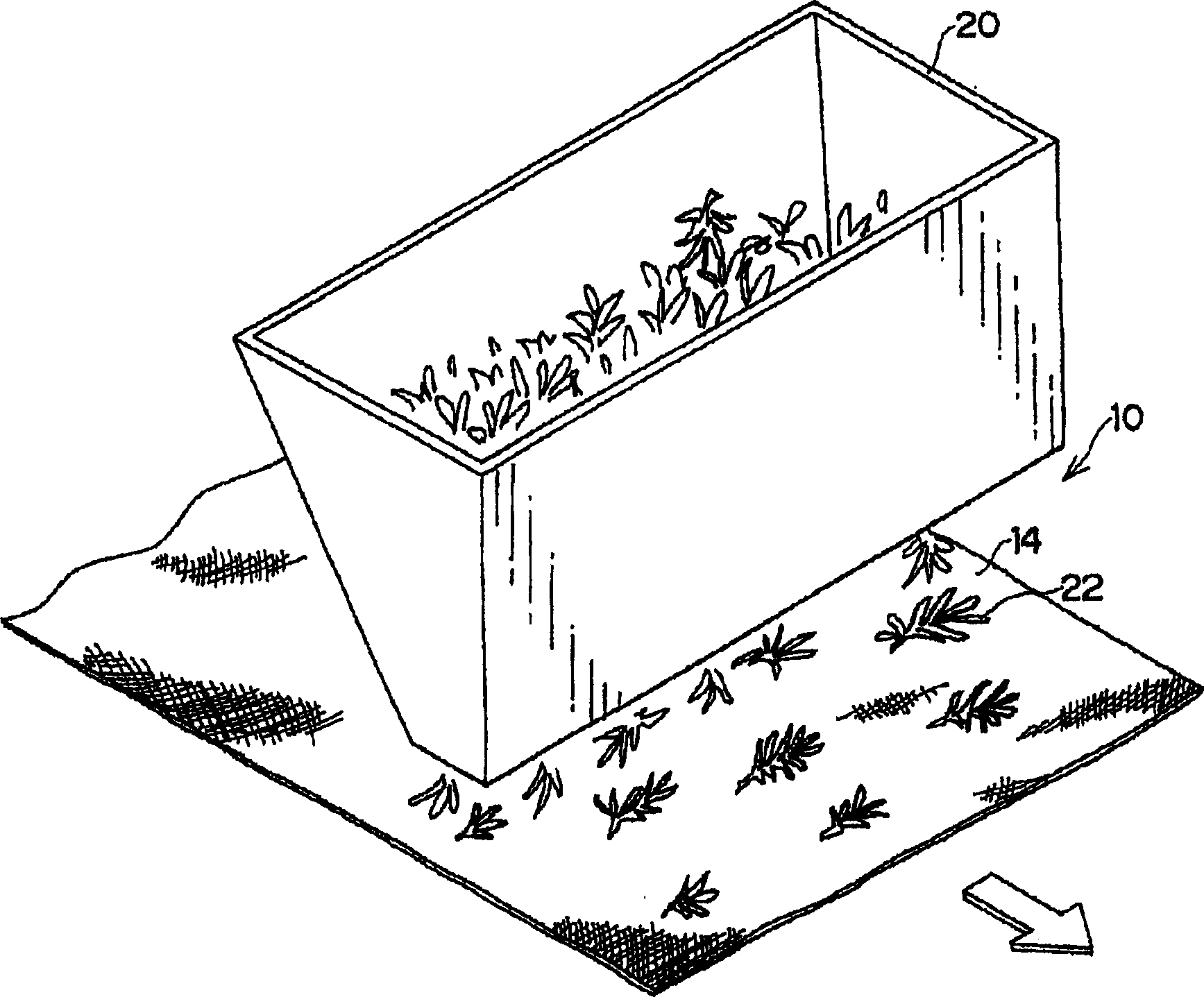

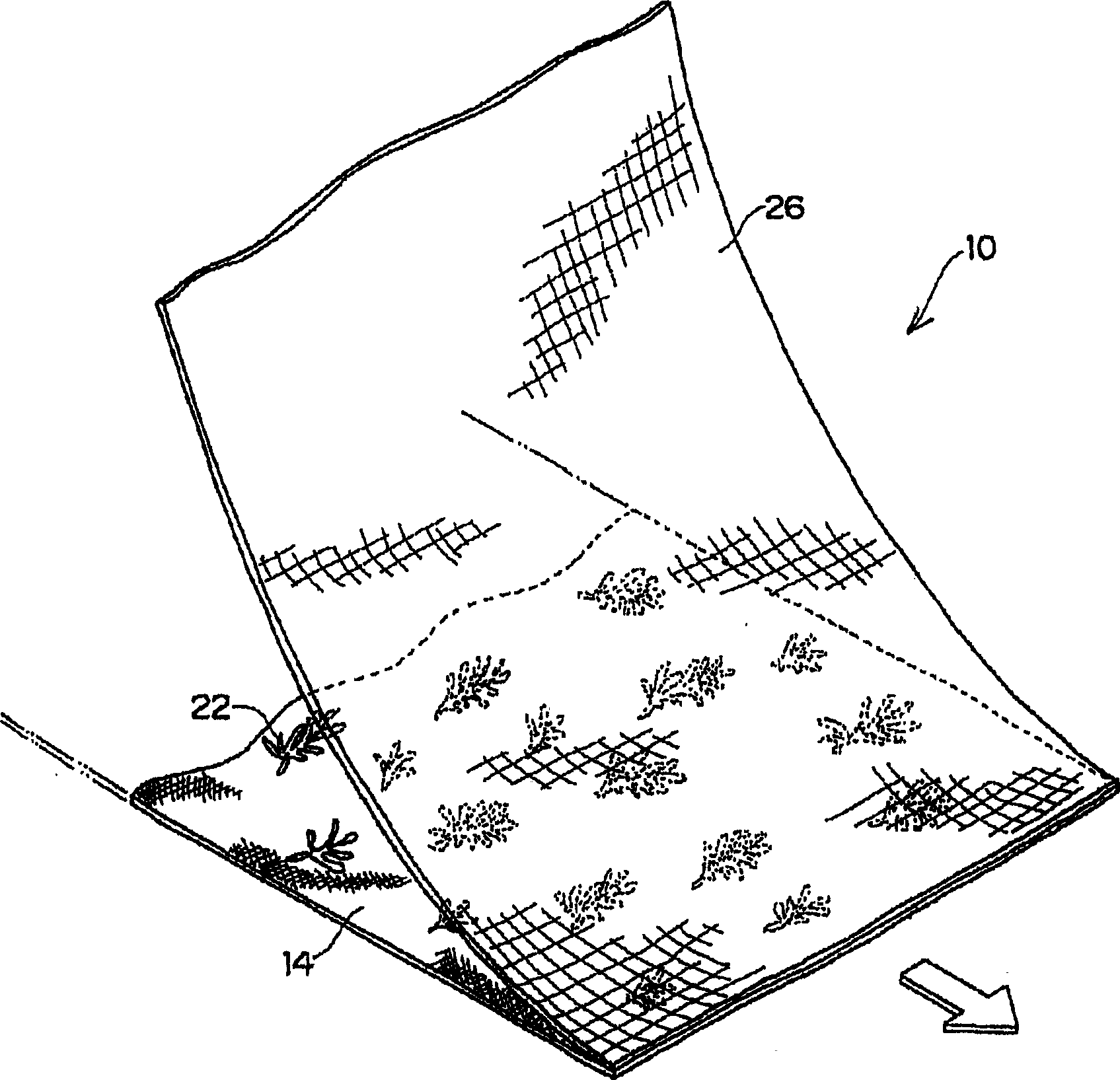

[0057] figure 1 The manufacturing process of the vegetal sheet 10 is shown.

[0058] The base sheet 14 serving as the base of the plant sheet 10 is wound around the winding core 12 provided on the delivery side. One end of the base sheet 14 is drawn out horizontally from the winding core 12, sent out by the delivery roller 16, and wound up on the winding core 18 provided on the winding side.

[0059] The base sheet 14 is a belt-shaped mesh-like material. For example, if a cotton fabric with a large mesh is used, the roots of plants (for example, succulents such as sedum) pass through the mesh of the base layer 14 and easily penetrate into the soil. In addition, it also has the advantage that the thin base layer 14 is easily integrated into the soil. Furthermore, if a biodegradable material is used as the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com