Multi three-phase AC excitation pumped storage asynchronous generator/motor

A pumped storage and electric motor technology, applied in the direction of asynchronous induction motors, synchronous generators, electrical components, etc., can solve problems such as complex inverter structure, grid harmonic pollution, low power factor, etc., to solve and improve heat generation problems Potential waveform and effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

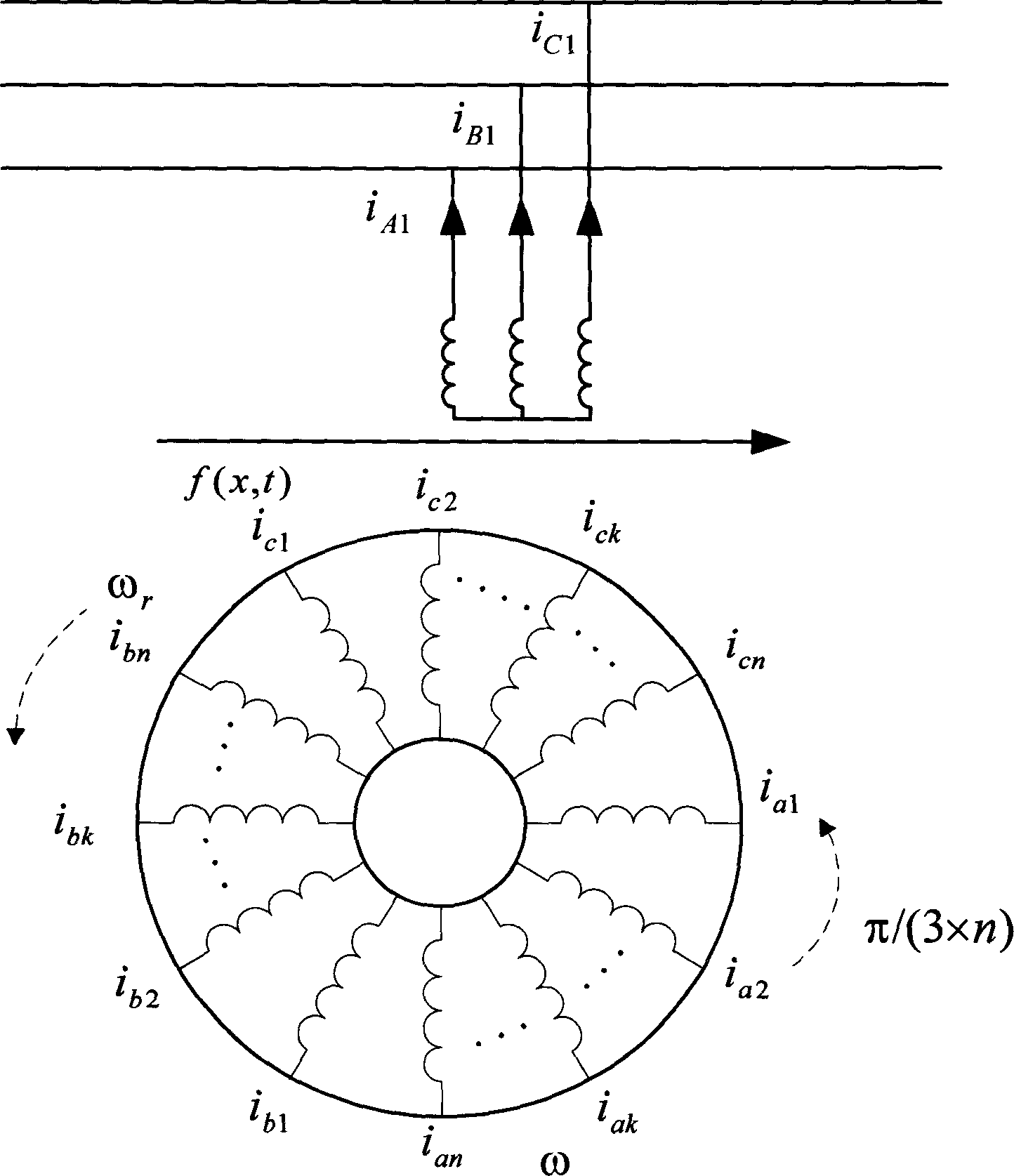

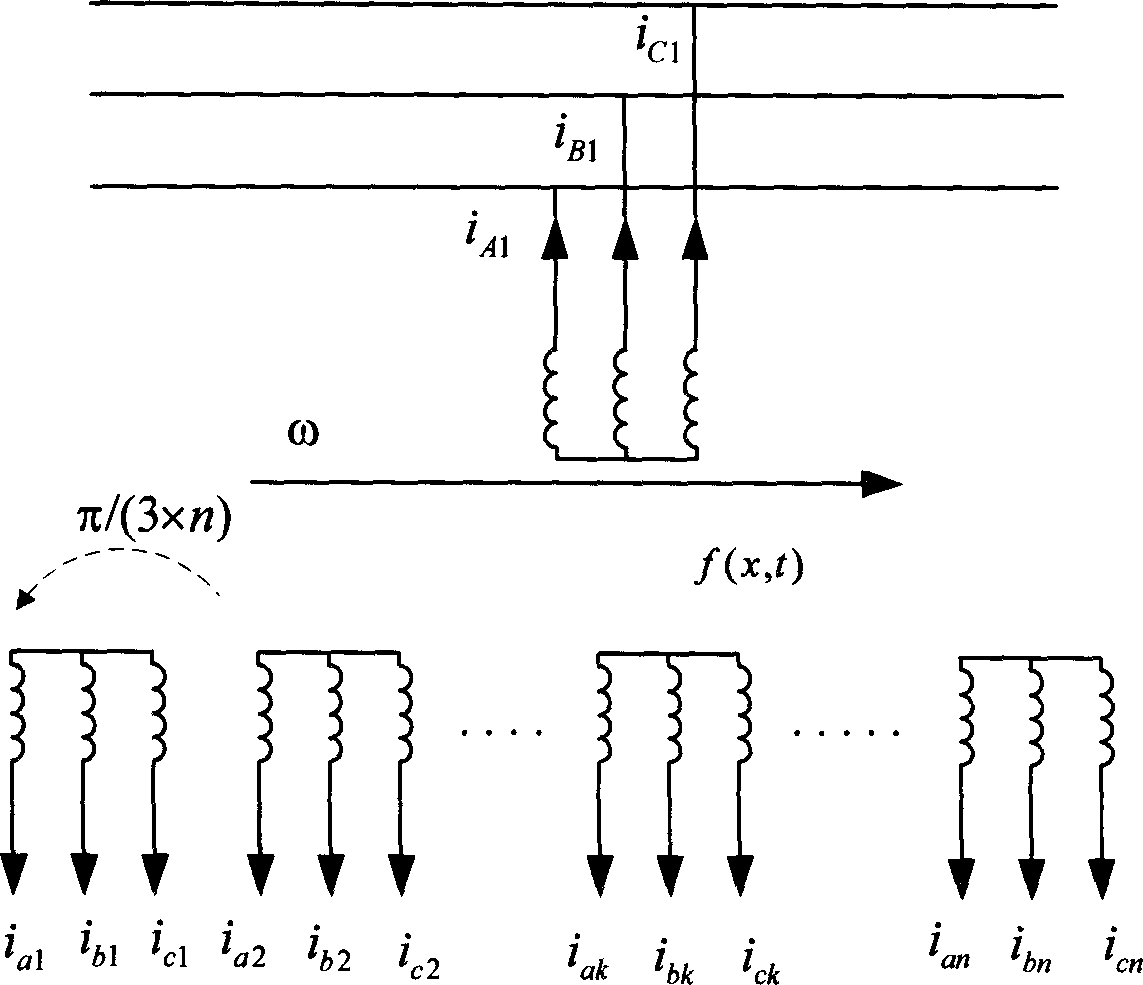

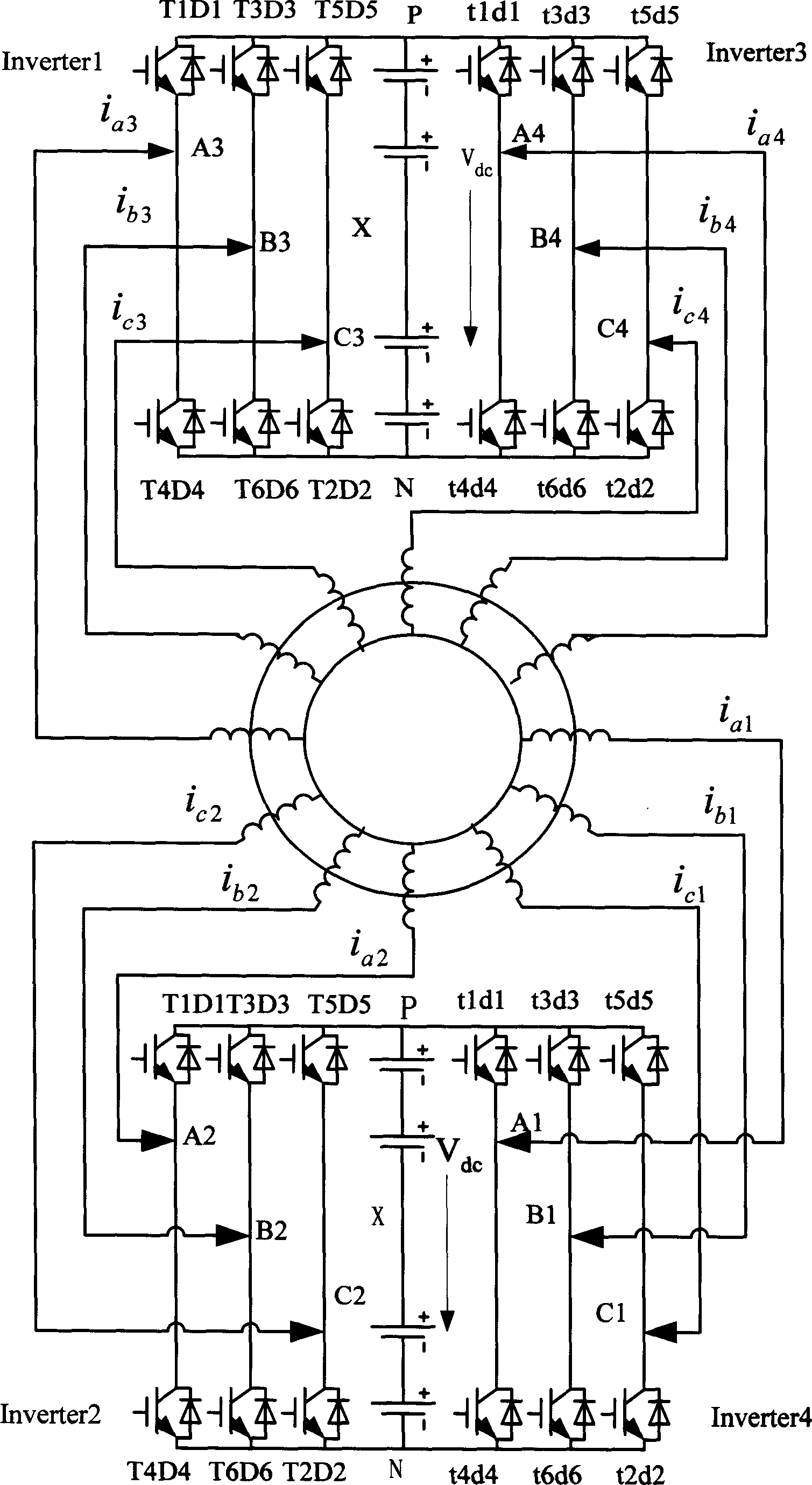

[0052] Instructions attached Figure 5 It is an embodiment of multiple three-phase AC excitation pumped storage power generation / motor. The power of the motor is 330MW, the voltage is 18KV, and the rated speed of the motor is 500rpm. The stator winding of the generator / motor is three-phase and directly connected to the power frequency grid, while the rotor winding has multiple sets of independent three-phase symmetrical windings on the circuit. The motor rotor wave winding structure is shown in Figure 5 . In the rotor multi-phase system, the winding connection diagram of the 4×3 phase rotor winding is adopted. It can be seen from the winding connection diagram that 4 groups of three-phase symmetrical windings are included in the 4×3-phase system. In this embodiment, the number of rotor slots of multi-three-phase AC excitation pumped storage asynchronous generator / motor is Z=216, and the magnetic pole The number 2p=12, the number of slots per pole and each phase q=1.5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com