Multi-rubbing-bucket fully-automatic tea kneading machine

A fully automatic, kneading machine technology, applied in the direction of tea processing before extraction, can solve the problems of uneven quality of finished tea, unsuitable for joining the production line, manual operation, etc., to achieve continuous and easy continuous production , to achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

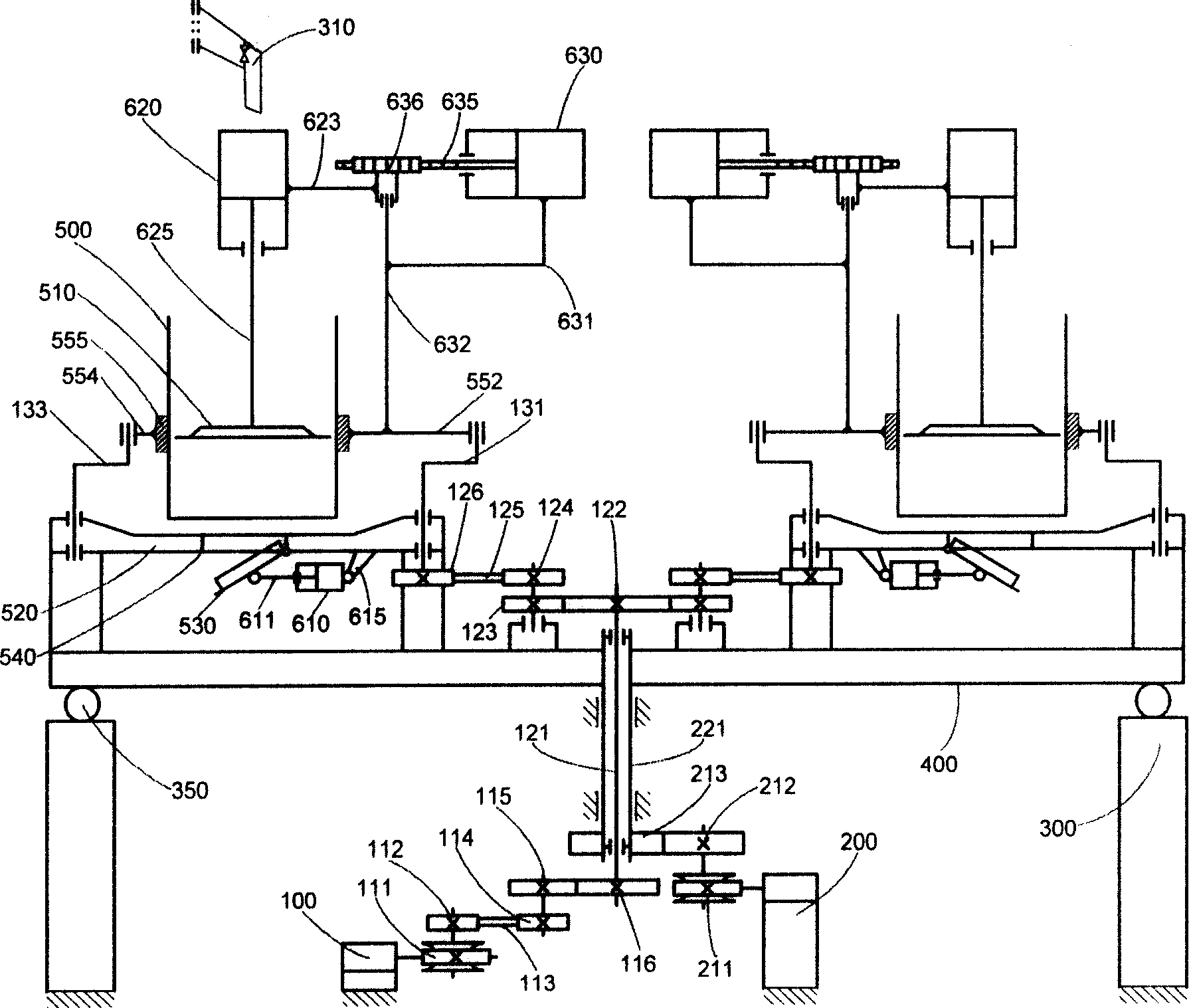

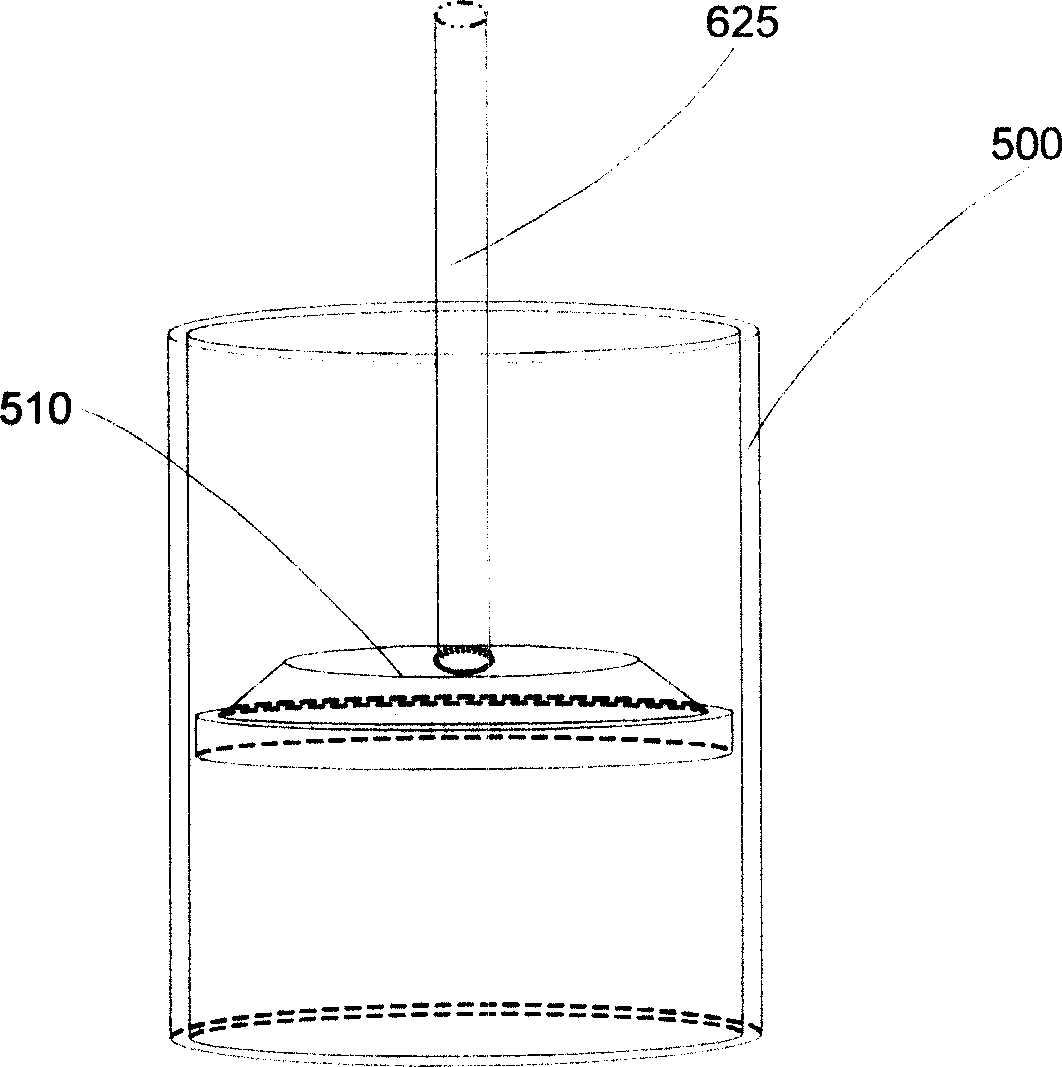

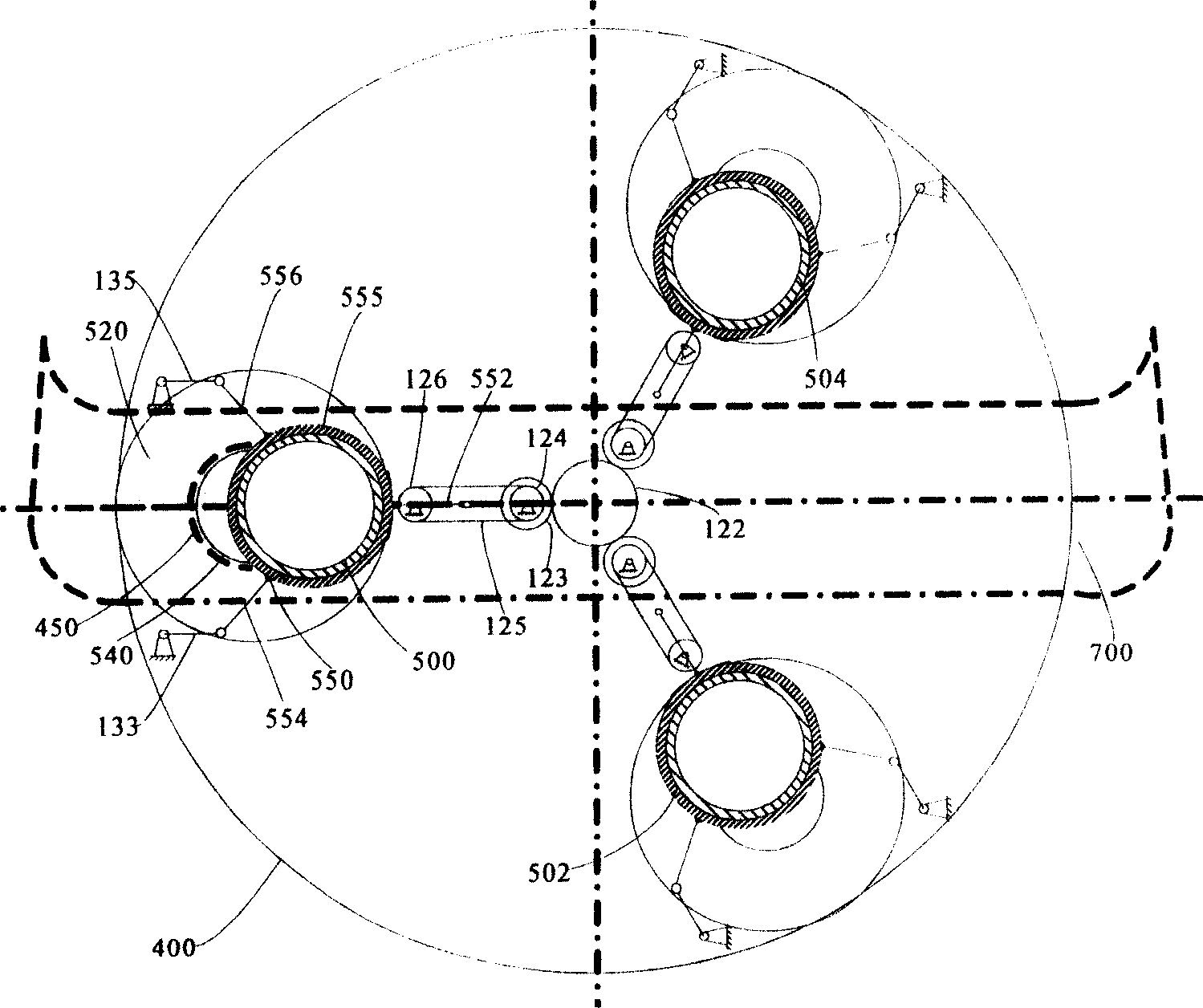

[0019] Such as Figure 1 ~ Figure 3 As shown, take the use of three kneading mechanisms as an example. The three kneading mechanisms are equally divided on the tray 400 and are directly connected with the tray 400. The tray 400 is supported on the machine base 300 by the plane bearing 350 and can rotate around its own center. The three kneading mechanisms share a feeder 310 , and the feeder 310 is supported by a fixed bracket and is located at a feeding position above the tray 400 . Before feeding, each kneading mechanism must make its kneading bucket reach the feeding position, and then, the green leaves drop from the feeder 310 into the kneading bucket of this kneading mechanism. The three kneading mechanisms are all at the same position for unloading. The kneading mechanism at the unloading position has its tea outlet 540 located directly above the belt transmission system 700. When unloading, the kneading leaves pass through their respective tea outlets and trays 400. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com