Bullet shell multi-station continuous shaping punching process

A multi-station, warhead technology, which is applied in the stamping process of bullet shells, to achieve the effects of reducing the deformation area, saving manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Blanking and drawing the sheet to obtain a Yu-shaped blank with a diameter of 248 mm and a wall thickness of 1.2 mm;

[0023] 2) carrying out annealing and saponification treatment with the Yu-shaped blank;

[0024] 3) Continuous stamping and forming of the processed yu-shaped blank on a multi-station press to obtain a bullet case. The specific sequence of steps is:

[0025] ① Feeding;

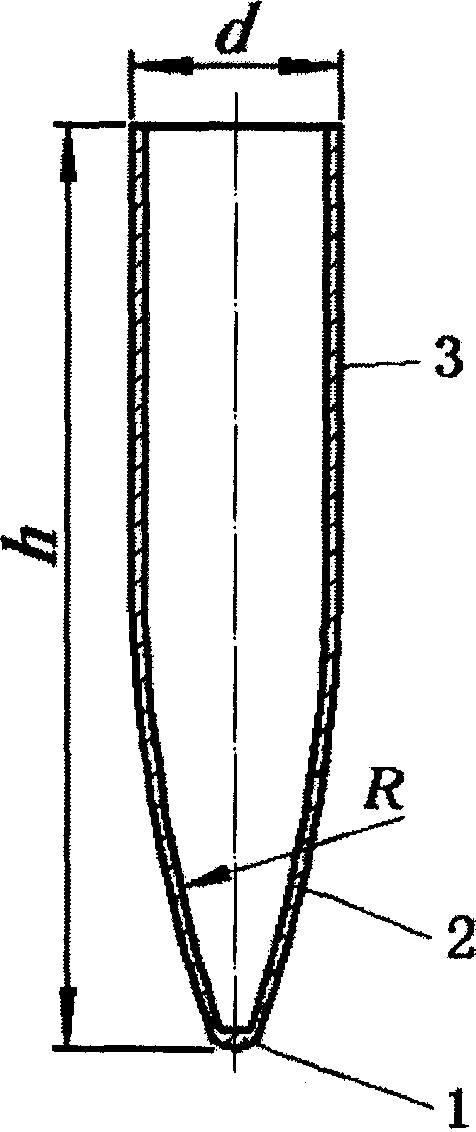

[0026] ② Perform three thinning and deep drawing to become an intermediate process piece with diameter d = 14.93mm and wall thickness t = 0.9mm, such as image 3 shown;

[0027] ③ cut the intermediate process parts;

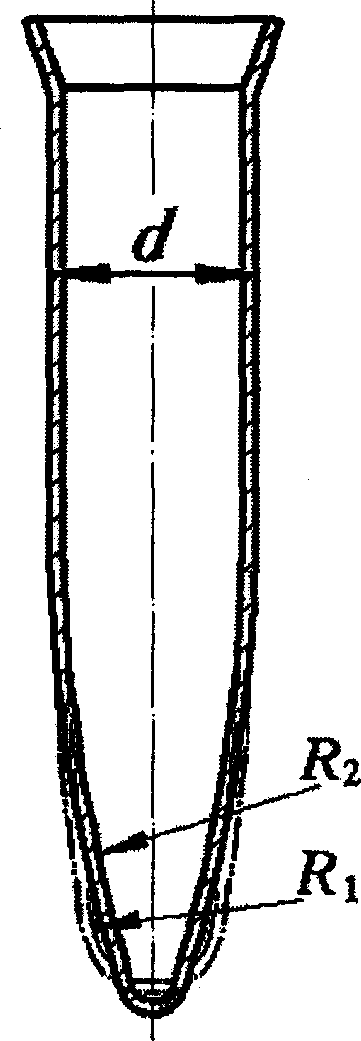

[0028] ④ After four thinning and deep drawing (diameters: d 1 = 11.8mm, d 2 =9.8mm, d 3 =7.8mm, d 4 =6.8mm, such as Figure 4 Shown), forming the arc-shaped cone part of the warhead;

[0029] ⑤Reshaping the formed bullet case;

[0030] ⑥ Delivery.

Embodiment 2

[0032] 1) with the first 1) operation in embodiment 1;

[0033] 2) with the 2nd) operation in embodiment 1;

[0034] 3) Continuous stamping and forming of the processed yu-shaped blank on a multi-station press to obtain a bullet case. The specific sequence of steps is:

[0035] 1. with the 1. step of the 3rd) operation in embodiment 1;

[0036] 2. with the 2. step of the 3rd) operation in embodiment 1;

[0037] 3. with the 4th step of the 3rd) operation in embodiment 1;

[0038] 4. with the 3. step of the 3rd) operation in embodiment 1, namely carry out otch to the warhead casing that forms;

[0039] 5. with the 3rd in embodiment 1) the 5th step of operation;

[0040] 6. the same as the 6th step of the 3rd) operation in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com