Method for extracting passiflora seed oil from passiflora seeds

A technology for seeds and lotus seeds, which is applied in the field of extracting passionflower seed oil from passionflower seeds by using supercritical CO2 extraction technology, can solve the problems of low purity, long extraction process, low yield and the like, and achieves the technological process. Simple, no solvent residue, high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

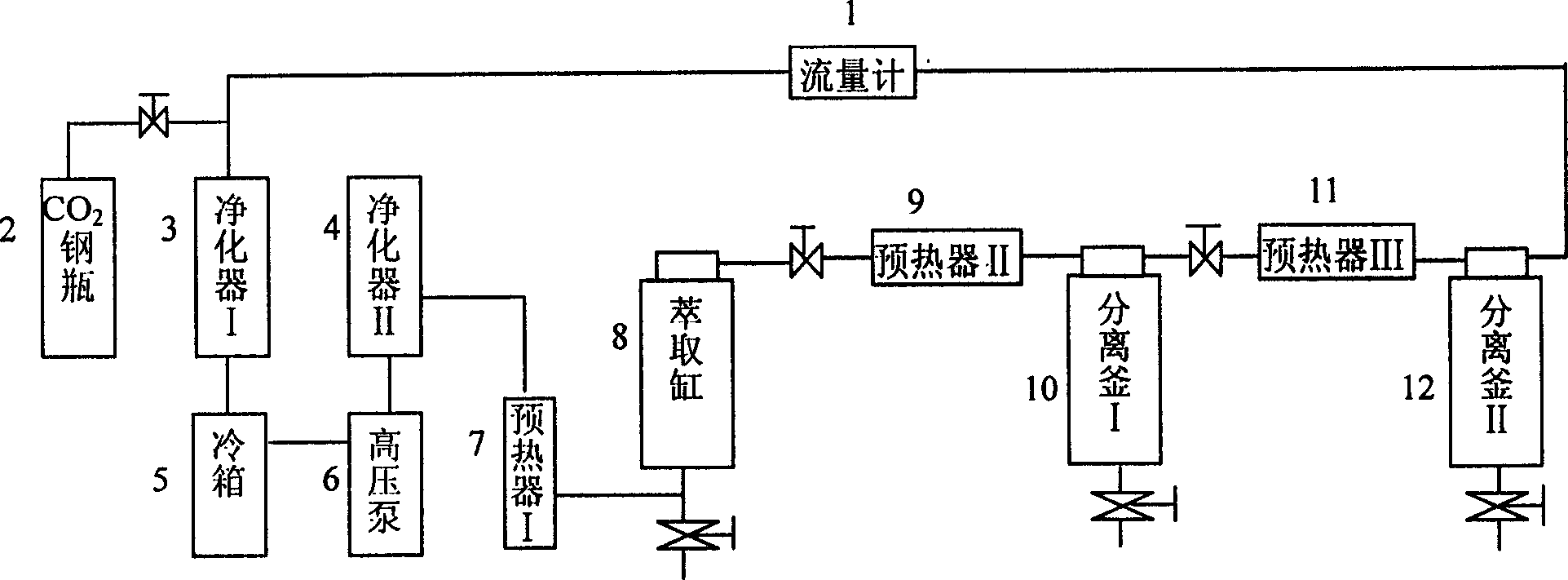

[0011] (1) 2 kilograms of passionflower seeds are washed and dried, pulverized into 30 orders and put into the barrel of 5L extraction tank 8; (2) turn on refrigeration and cold cycle, and the temperature of cold box 5 is set to 0°C; Set the temperature of extraction cylinder 8 to 45°C, the temperature of separation kettle I10 to 40°C, the temperature of separation kettle II12 to 55°C, and turn on the CO 2 Cylinder 2, CO 2 Come out from the steel cylinder 2, enter the cold box 5 for liquefaction through the gas purifier I3, and then start the high-pressure pump 6 to convert the CO 2 After the purifier II4 and the preheater I7 enter the extraction cylinder 8, boost the pressure to 30MPa, making it a supercritical fluid for extraction in the extraction cylinder; (3) the CO 2 The fluid is decompressed from the extraction cylinder 8 and enters the preheater II9 to be preheated before entering the separation system. In order to realize the complete separation of unsaturated fatty ...

Embodiment 2

[0013] 2 kilograms of passionflower seeds are washed and dried, crushed to 40 mesh; the pressure of the control extraction cylinder is 15Mpa, the temperature is set to 35°C, the pressure of the separation kettle I is adjusted to 8Mpa, and the temperature is set to 55°C, and the separation kettle II The temperature setting is 40 DEG C, and other is the same as embodiment 1, extracts 5 hours, collects 516 grams of fats and oils, and extraction rate is 25.8%.

Embodiment 3

[0015] Control the pressure of the extraction cylinder to 20Mpa, set the temperature to 55°C, adjust the pressure of the separation tank I to 10Mpa, set the temperature to 35°C, set the temperature of the separation tank II to 35°C, and keep the rest of the conditions unchanged, extract for 4.5 hours, collect 500 grams of oil, the extraction rate is 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com