Hydroelectric power generating apparatus

A power generation device and water conservancy technology, which is applied in the direction of hydroelectric power generation, machines/engines, impact engines, etc., can solve problems such as vibration and swing of water turbines, cavitation erosion of water turbines, uneven force on blades of water turbine impellers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The hydropower generation device of the present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

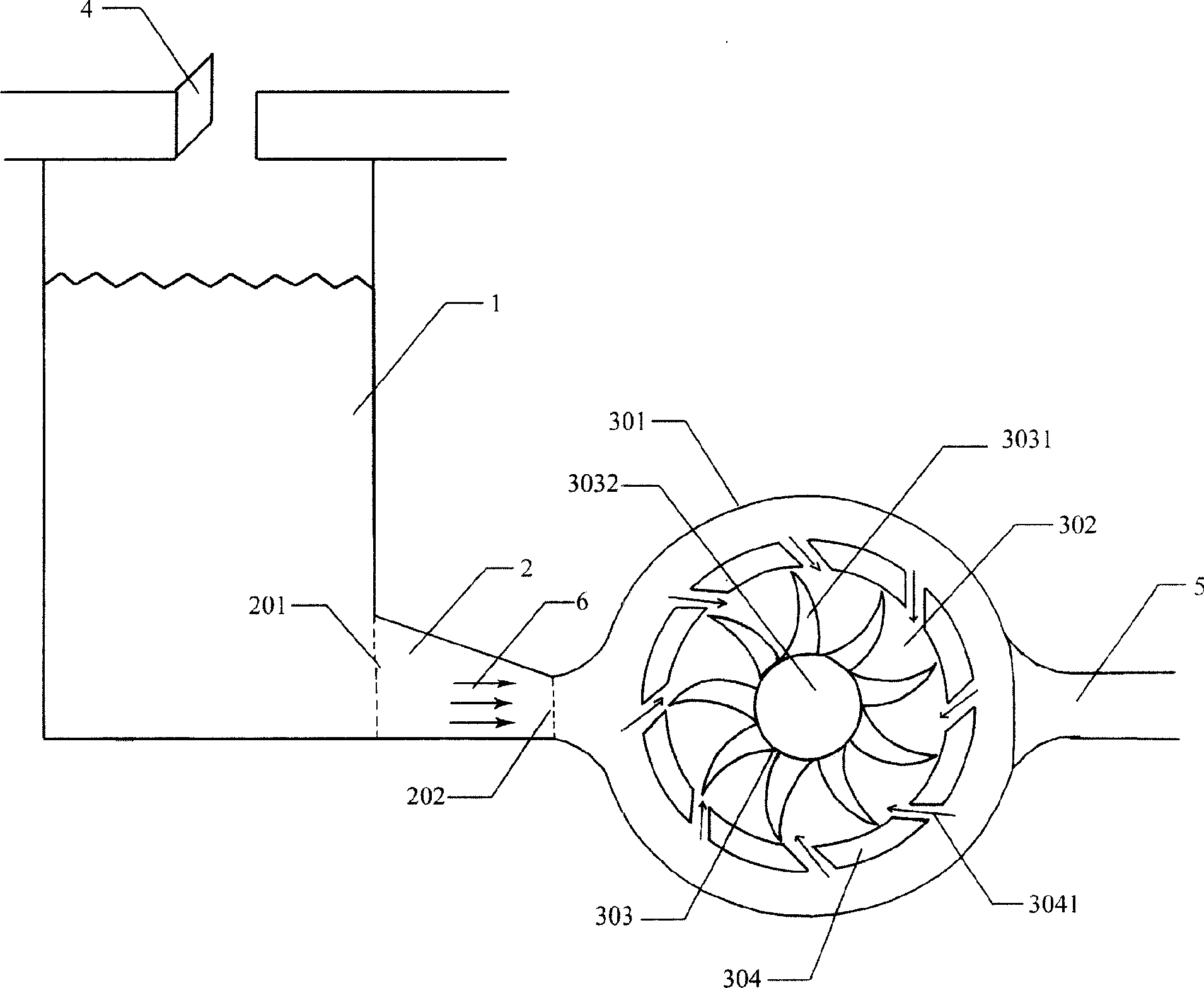

[0014] figure 1 It is a schematic diagram of the principle of a specific implementation of the hydroelectric power generation device of the present invention. In the figure, the hydroelectric power generation device also includes a water pool 1 with scaling and pressurization, and a water inlet culvert 2 with a scaling and pressurization function is built at its lowermost end. Its water inlet 201 communicates with the pool 1, and its water outlet 202 communicates with The water turbine volutes 301 are connected. In this embodiment, the flow area of the water inlet end 201 of the water inlet culvert 2 is larger than the flow area of the water outlet end 202. After the water flows through the water inlet culvert 2, the flow velocity has been scaled and increased, and the flow surface unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com