Bearing-free switch magnetic-resistance starting generator and control method

A starter generator and switched reluctance technology, applied to the shape/style/structure of winding conductors, can solve the problems of limited application range of switched reluctance motors, motor torque ripple, electromagnetic noise, etc., to improve reliability and High-speed adaptability, reduce motor noise and torque ripple, and reduce mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

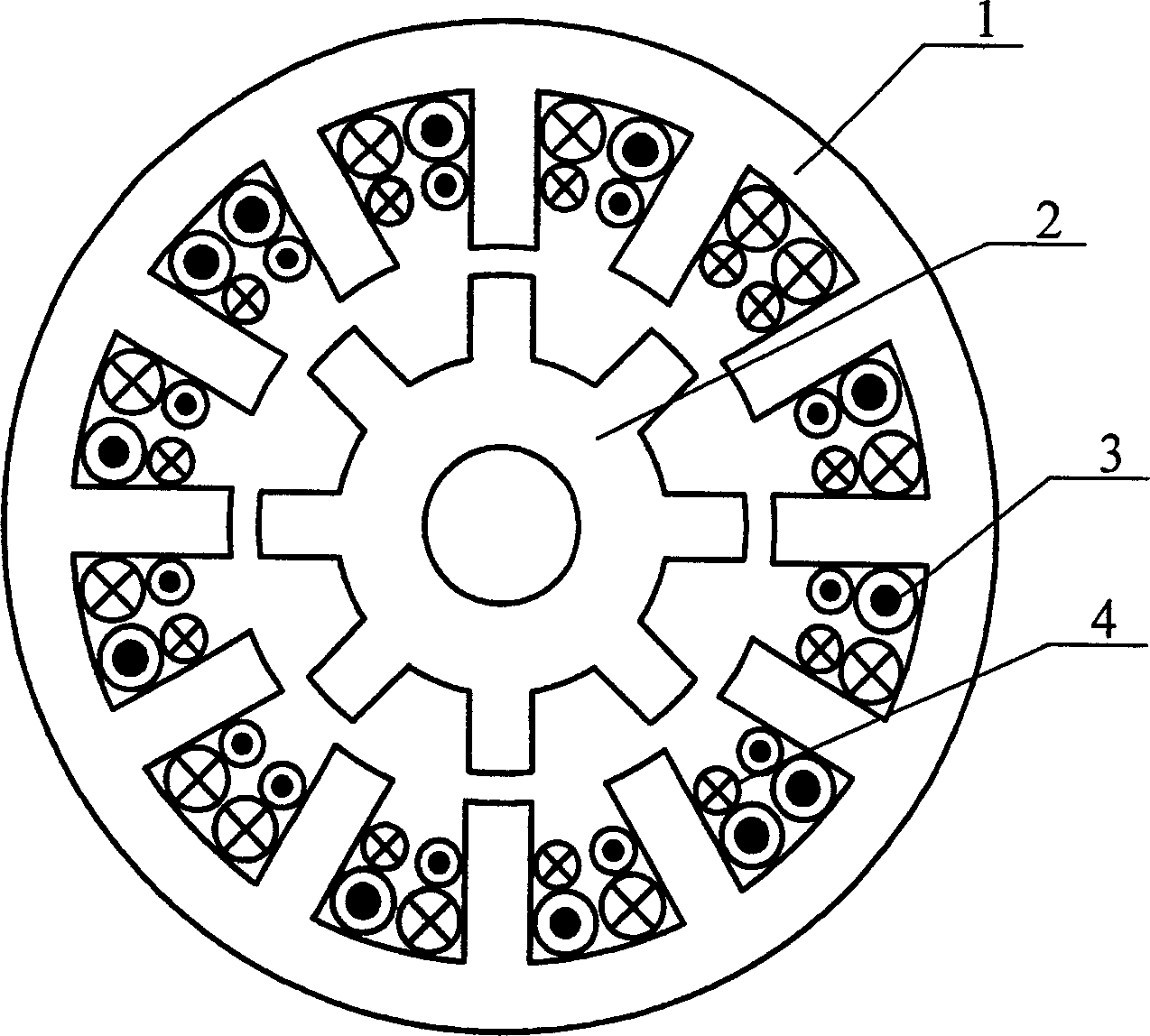

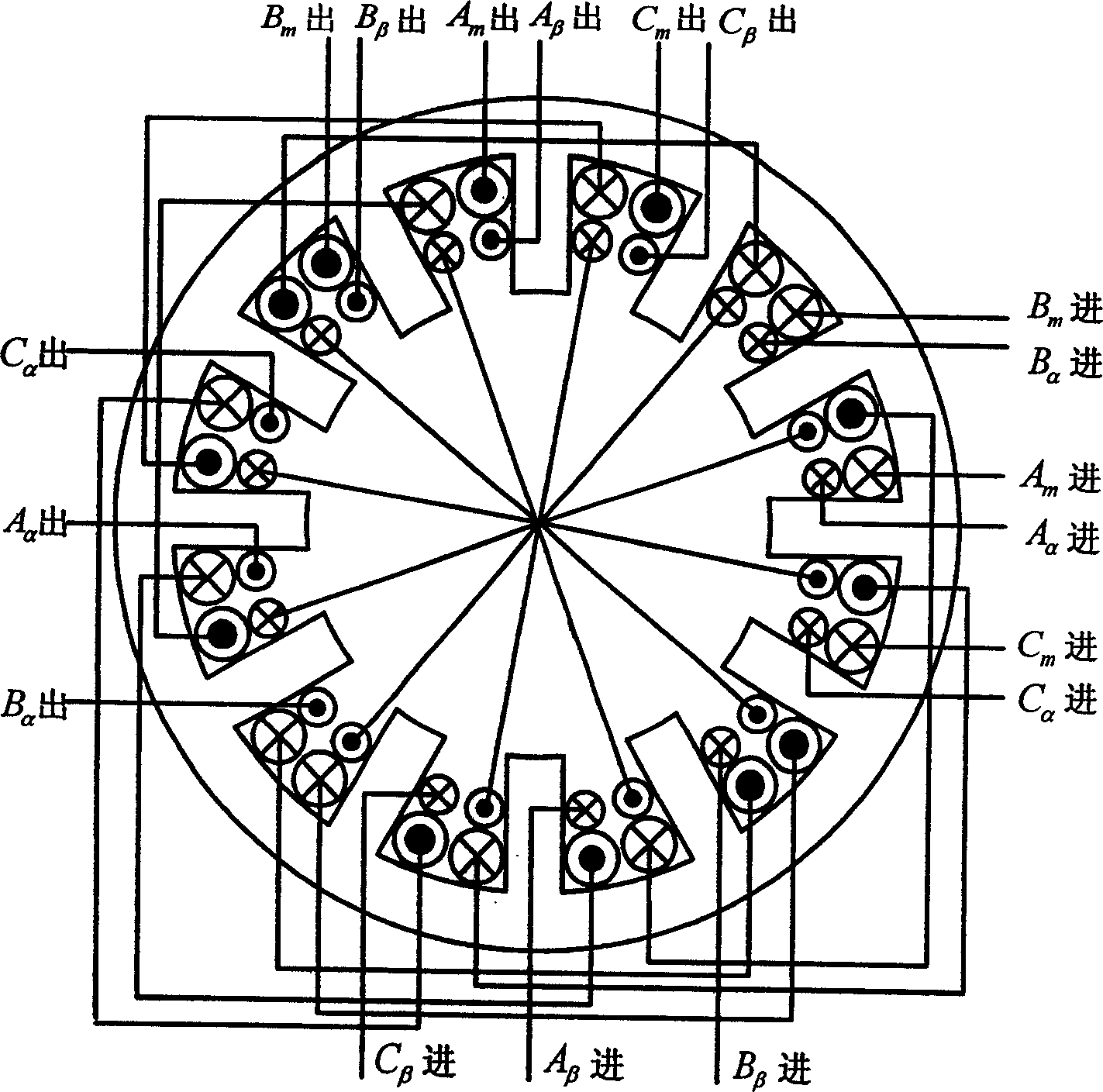

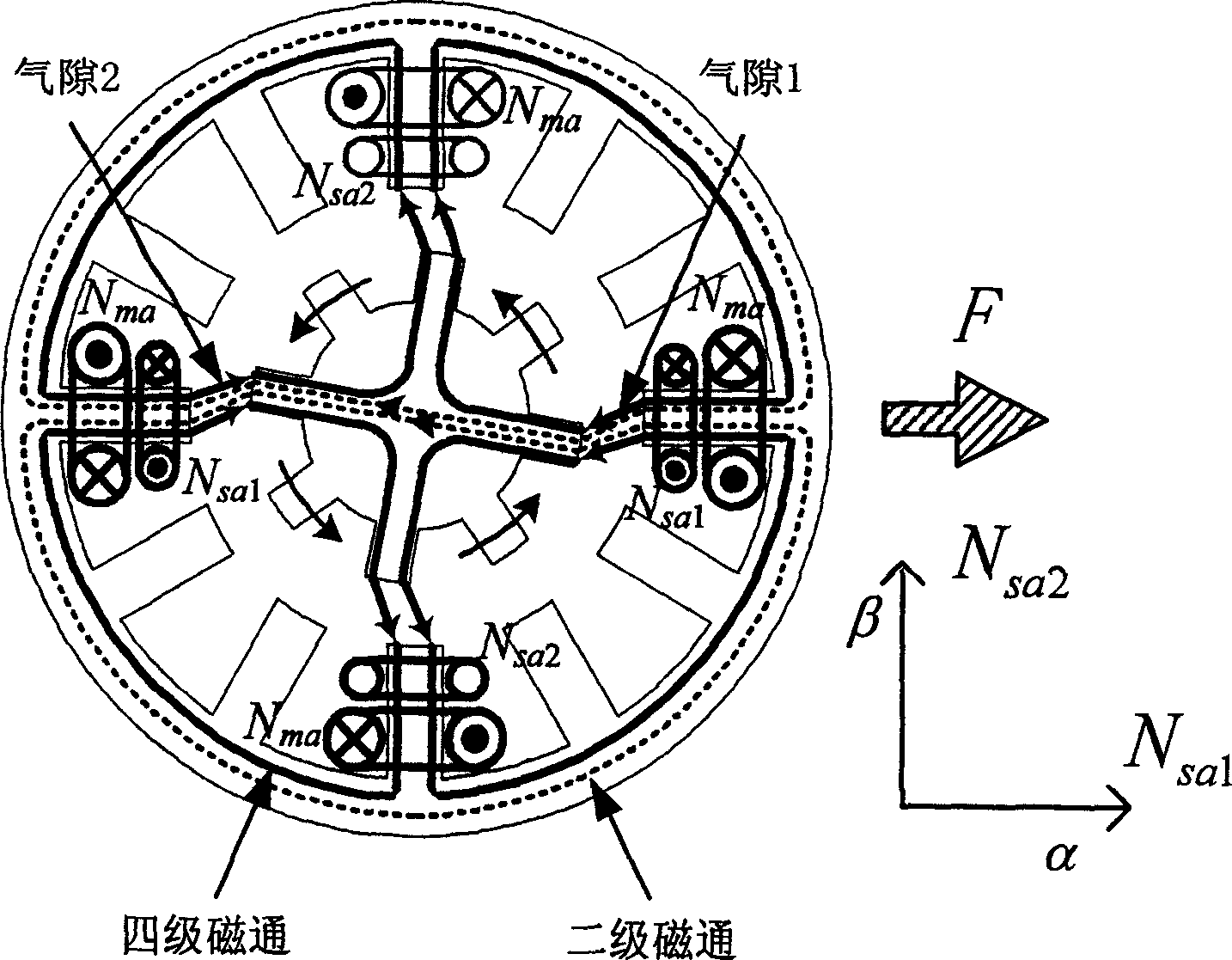

[0018] The schematic structural diagram of the bearingless switched reluctance starter generator shown in Fig. 1 is a cross-sectional schematic diagram of a bearingless switched reluctance motor with a 12 / 8 structure. The motor of the present invention includes a stator 1 and a rotor 2 without windings. It is characterized in that the teeth of the stator 1 are embedded with a concentrated torque winding 3 and a suspension winding 4 at the same time, and the power converter of the torque winding adopts a three-phase asymmetrical half-bridge topology circuit. structure, the power converter of the suspension winding adopts a three-phase four-leg topology circuit structure. Figure 2 is a schematic diagram of the connection between the torque winding and the suspension winding of a bearingless switched reluctance starter generator with a 12 / 8 structure. A phase torque winding A in Figure 4 m , by A m In turn, the four torque windings of phase A are connected in series to A m out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com