Apparatus for molten cutting off connecting portions of serial sausages

A connecting part and sausage technology, which is applied in sausage making, slaughtering, food science, etc., can solve the problems of not being able to completely prevent leakage of raw materials, complicated device structure, difficult cleaning and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, examples of the present invention will be described in detail with reference to the drawings, but the technical scope of the present invention is not limited by the examples.

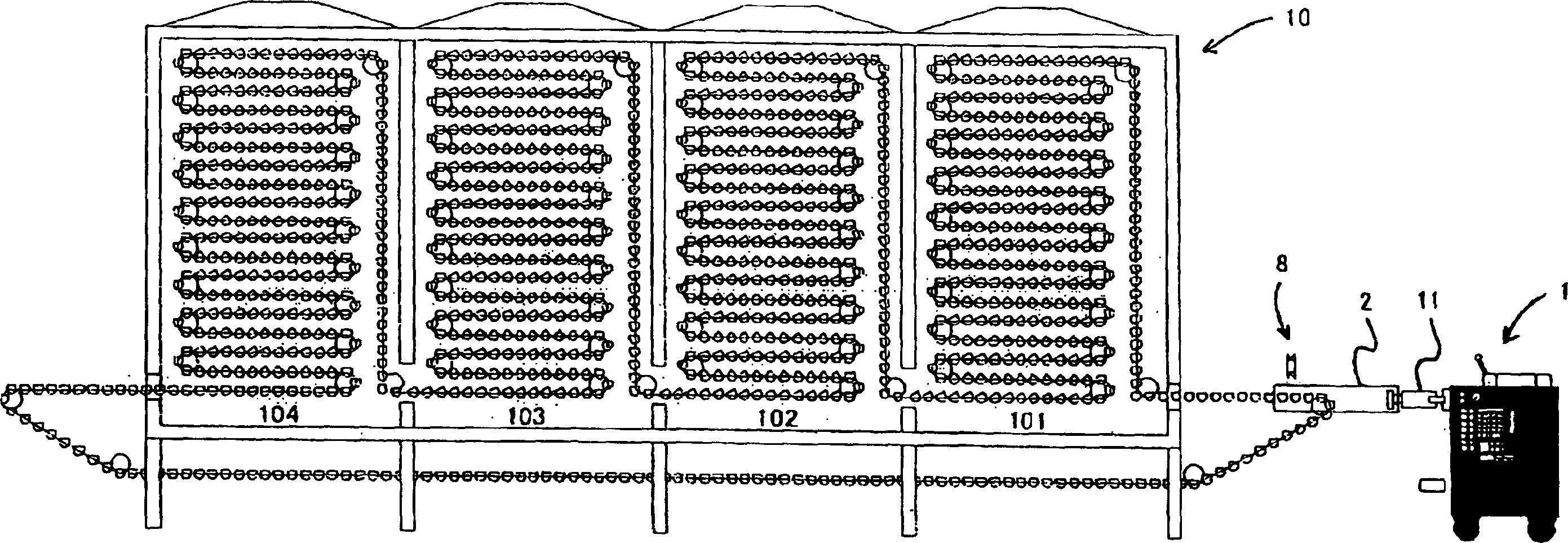

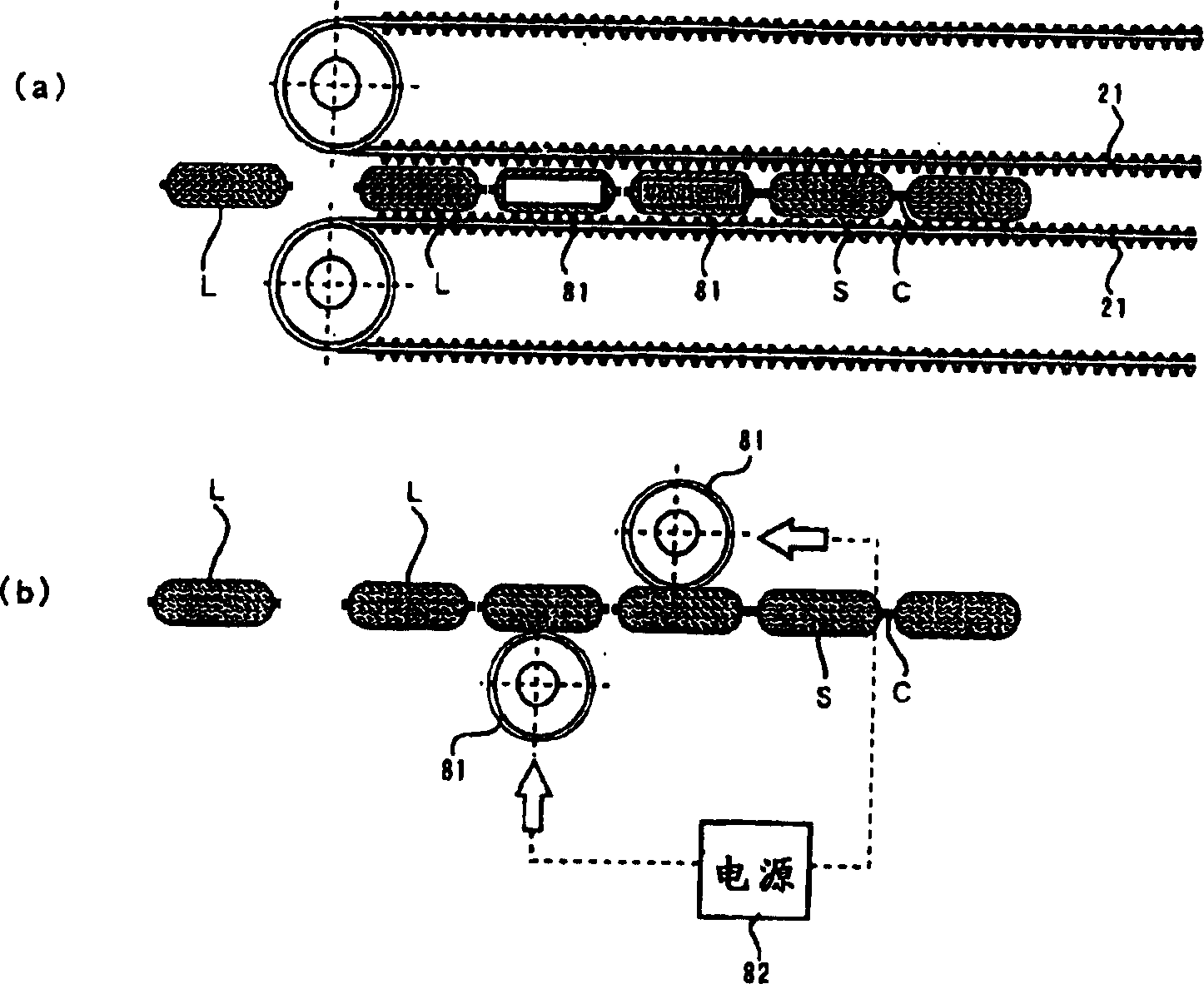

[0052] As shown in the figure, 1 is the filling device, 11 is the discharge port of the filling device, 2 is the conveyor, 21 is the chain conveyor, 22 is the belt conveyor, 8 is the fuse device installed on the conveyor, and 81 is the electrode , 82 is a power supply, 83 is an insulator, 9 is a conveyor, 10 is a heat treatment device, S is a series sausage, L is a separate section, and C is a connecting part of a series sausage.

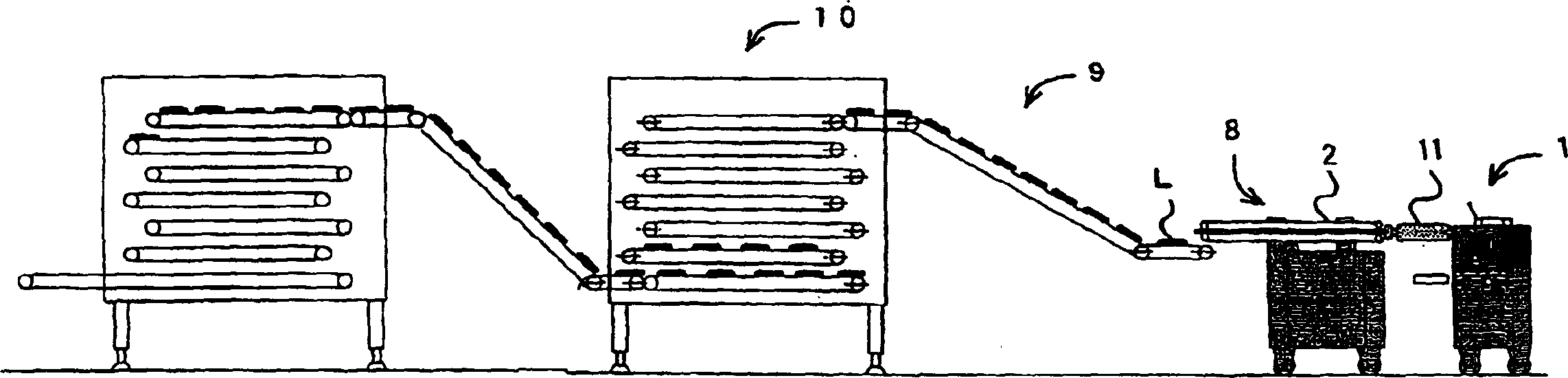

[0053] figure 1 with figure 2 Respectively represent the manufacturing process of sausage products using discontinuous type and continuous type fuse device of the present invention. Use the filling device 1 to squeeze sausage raw materials into the skin of natural sausage or artificial edible sausage, and form a serial sausage S by twisting when the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com