Method for completely recycling straws

A recycling and straw technology, applied in the field of straw, can solve the problems that can only be applied to furniture, tables, chairs, benches, high manufacturing methods and costs, and limited value of use, so as to achieve low production cost, low cost, and enhanced practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

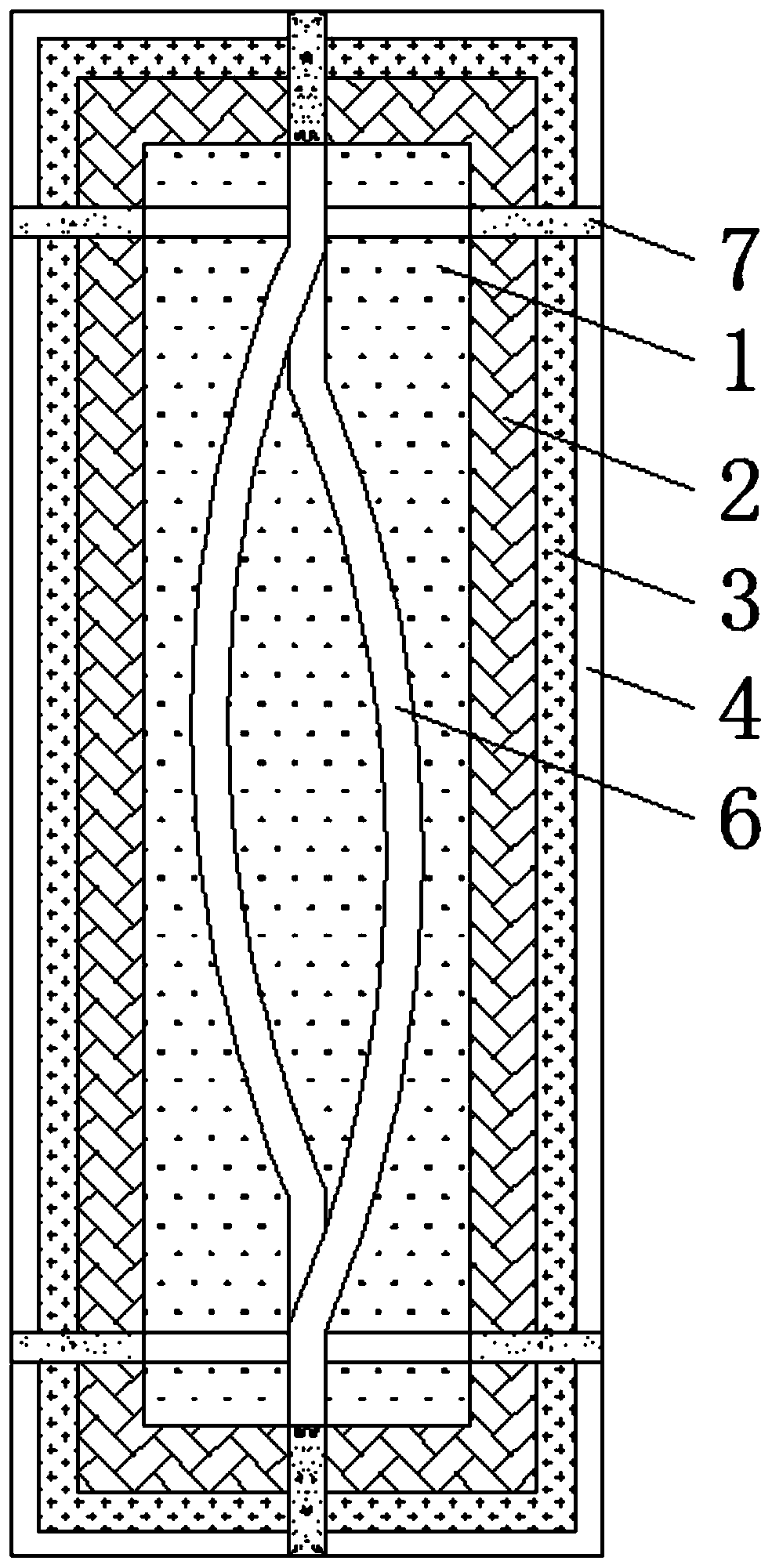

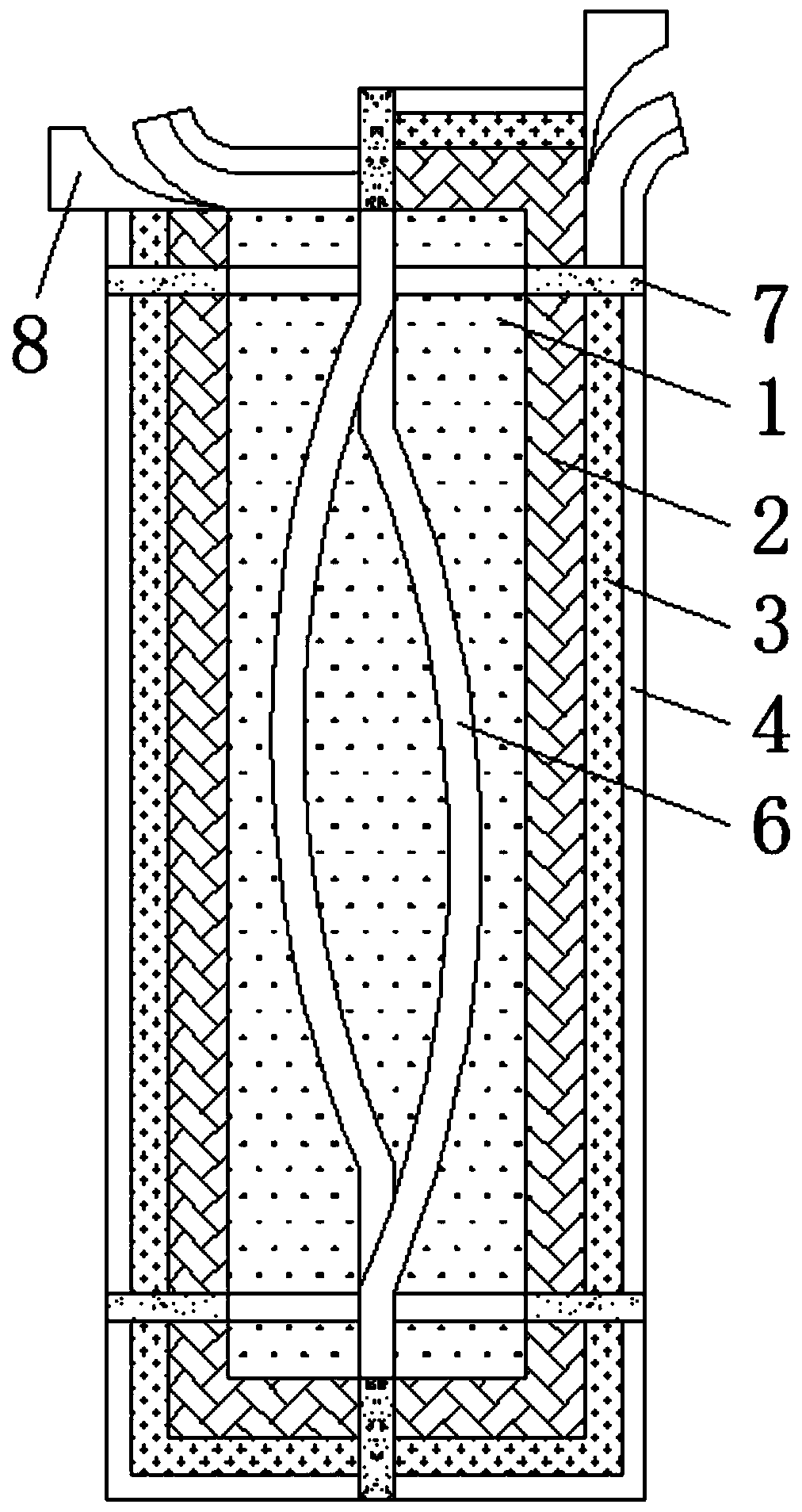

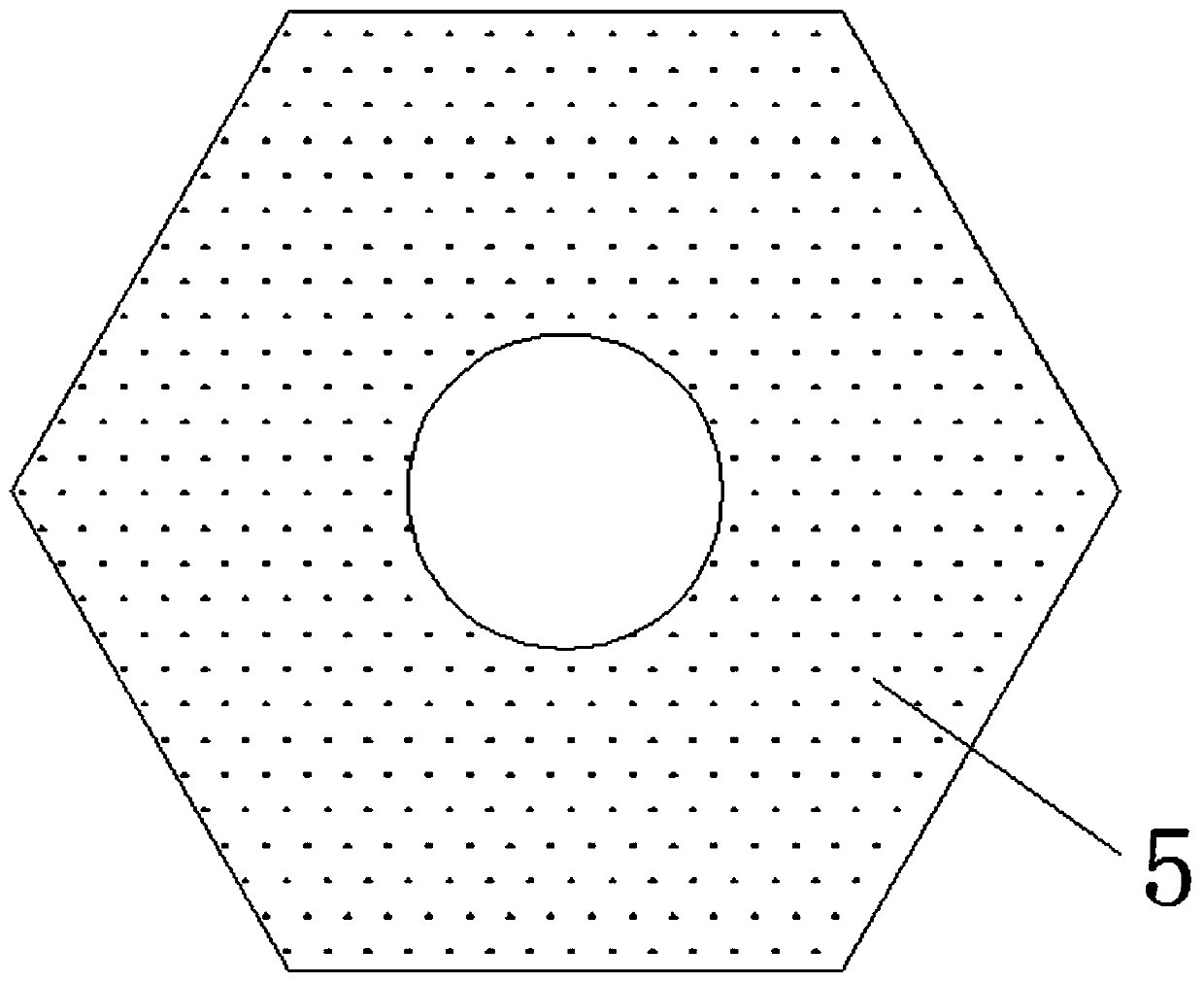

[0052] refer to Figure 1-3 , a method for fully utilizing and recycling straws, S1, pre-treatment, the straws are collected and concentrated in the air, then carbonized, steam activated, and dried to form charcoal, and the straws are sprayed with water during the concentrated drying process until the moisture content of the straw between 13%;

[0053] S2, mashing the carbonized straw to form charcoal powder;

[0054] S3, add bonding agent in charcoal powder, put into mixer and stir evenly;

[0055] Further, the adhesive is composed of natural resin, and during the stirring process, the adhesive is added while stirring, and the amount of the adhesive added is 5%;

[0056] S4, the charcoal powder after mixing is put into the plank mould, is extruded by a hydraulic press to form a plank;

[0057] By setting step S4, the use value of charcoal powder can be pre-developed. The charcoal board made of charcoal powder is used in construction. On the one hand, it saves wood, is easy...

Embodiment 2

[0072] refer to Figure 1-3 , a method for fully utilizing and recycling straws, S1, pre-treatment, the straws are collected and concentrated in the air, then carbonized, steam activated, and dried to form charcoal, and the straws are sprayed with water during the concentrated drying process until the moisture content of the straw between 15%;

[0073] S2, mashing the carbonized straw to form charcoal powder;

[0074] S3, add bonding agent in charcoal powder, put into mixer and stir evenly;

[0075] Further, the adhesive is composed of natural resin, during the stirring process, the adhesive is added while stirring, and the amount of the adhesive added is 8%;

[0076] S4, the charcoal powder after mixing is put into the plank mould, is extruded by a hydraulic press to form a plank;

[0077] By setting step S4, the use value of charcoal powder can be pre-developed. The charcoal board made of charcoal powder is used in construction. On the one hand, it saves wood, is easy to ...

Embodiment 3

[0092] refer to Figure 1-3 , a method for fully utilizing and recycling straws, S1, pre-treatment, the straws are collected and concentrated in the air, then carbonized, steam activated, and dried to form charcoal, and the straws are sprayed with water during the concentrated drying process until the moisture content of the straw between 16%;

[0093] S2, mashing the carbonized straw to form charcoal powder;

[0094] S3, add bonding agent in charcoal powder, put into mixer and stir evenly;

[0095] Further, the adhesive is composed of natural resin, and during the stirring process, the adhesive is added while stirring, and the amount of the adhesive added is 12%;

[0096] S4, the charcoal powder after mixing is put into the plank mould, is extruded by a hydraulic press to form a plank;

[0097] By setting step S4, the use value of charcoal powder can be pre-developed. The charcoal board made of charcoal powder is used in construction. On the one hand, it saves wood, is eas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com