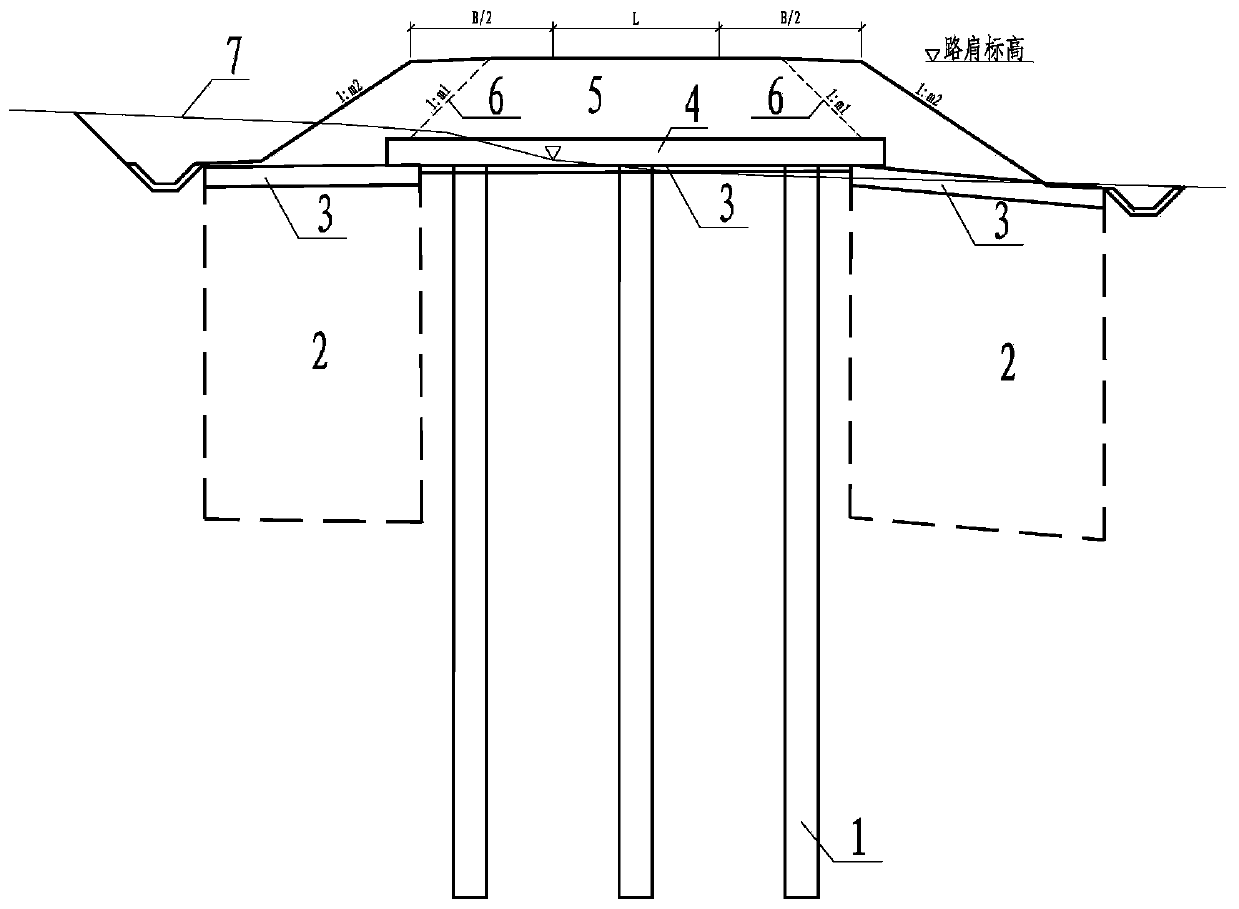

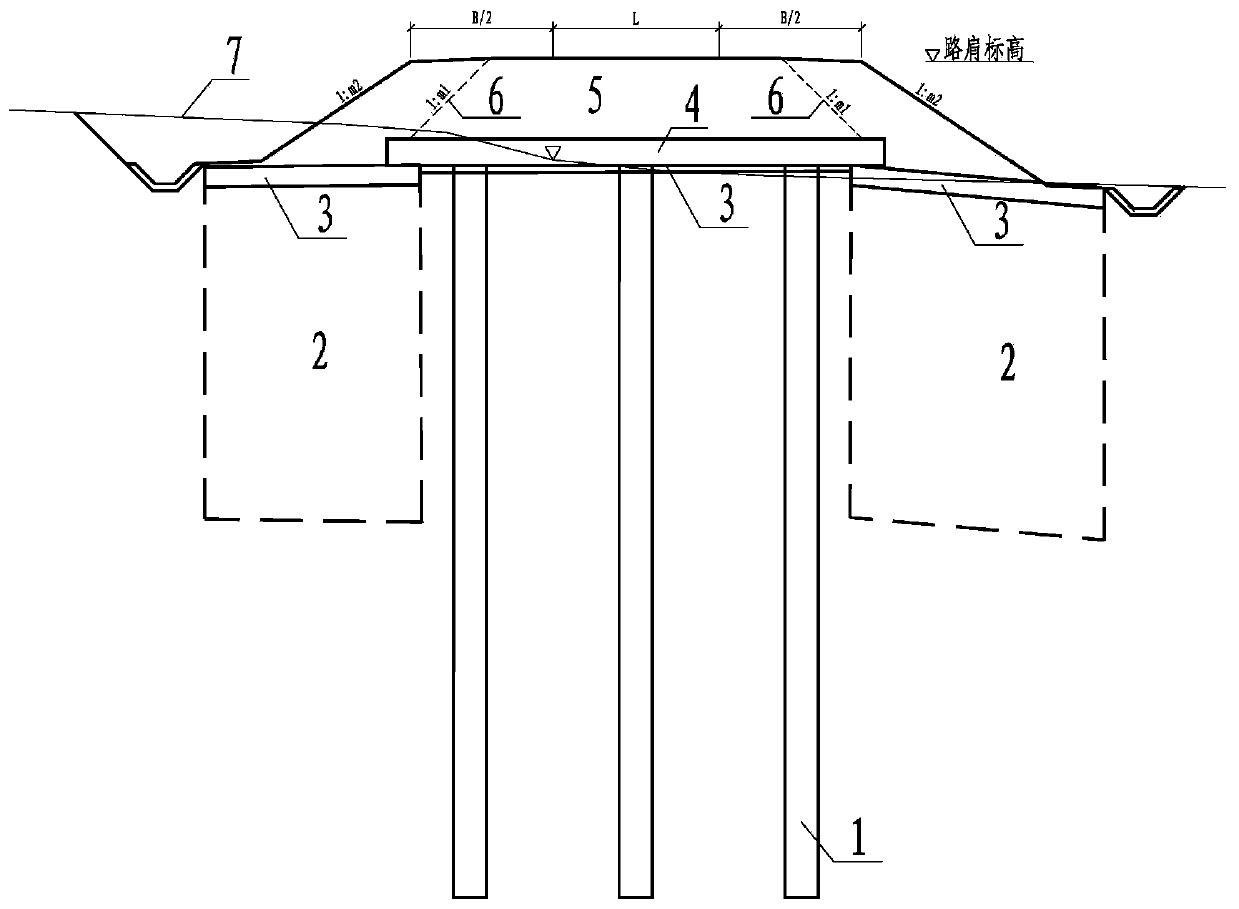

Construction method of high-speed railway fill subgrade in soft soil area

A high-speed railway and construction method technology, applied in roads, tracks, buildings, etc., can solve problems such as increased foundation treatment costs, complicated filler improvement procedures, deepening foundation treatment depth, etc., to ensure construction quality, ensure stability, and reduce project costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0051] The embodiment of the present invention discloses a construction method of high-speed railway filling embankment in soft soil area, as shown in the figure, it includes the following steps:

[0052] (1) Clean and level the original ground;

[0053] (2) Rigid piles within the scope of the construction load influence line;

[0054] After the site is cleared and leveled, the rigid piles within the scope of the construction load influence line after the foundation inspection is qualified;

[0055] (3) The soil mass between the slope toe of composite foundation reinforcement and the load influence range line;

[0056] (4) The bearing plate on the construction pile-slab structure;

[0057] After the bored pile is qualified, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com