High-hardness plastic floor subjected to coating hardening treatment

A high-hardness plastic and hardening treatment technology, which is applied in the field of plastic flooring, can solve the problems of reduced service life, broken plastic floor, and insufficient surface hardness, and achieve the effects of increasing service life, increasing hardening degree, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

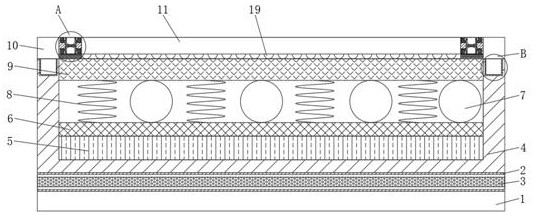

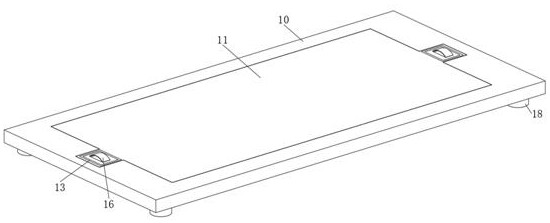

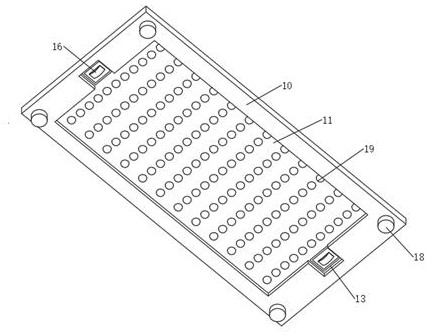

[0032] Such as Figure 1-5 As shown, the embodiment of the present invention provides a high-hardness plastic floor with coating hardening treatment, including a first substrate 1, a heating layer 2 is fixedly connected to the top of the first substrate 1, and an electric heating wire 3 is arranged inside the heating layer 2 , used to heat the plastic floor, the top of the heating layer 2 is fixedly connected with the second substrate 4, the materials of the first substrate 1 and the second substrate 4 are made of plastic material, which is convenient for connection and laying, the second The inside of the substrate 4 is provided with a sound-absorbing layer 5, the material of the sound-absorbing layer 5 is made of polyurethane foam, which is used to absorb the noise generated by the plastic floor, and the inside of the second substrate 4 is fixedly connected with a buffer layer on the top side of the sound-absorbing layer 5 6. It is used to buffer the pressure to the greatest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com