Probe for quick tester of hydrogen content in aluminium alloy melt and manufacturing method thereof

A technology for rapid measurement of aluminum alloy melts, applied in the field of metallurgy and casting, can solve the problems of inability to meet the needs of rapid detection and adjustment on the production site, small and medium-sized enterprises cannot use it for a long time, and the supporting probes are expensive, etc., and achieve high yield , Ease of processing, and the effect of improving the degree of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for manufacturing a probe for a rapid detector of hydrogen content in an aluminum alloy melt, the method comprising the steps of:

[0023] a. Take 16 parts of 150-mesh silicon carbide, 5 parts of bentonite, 2 parts of aluminum oxide powder, 1 part of copper oxide powder, and 4 parts of gypsum powder in the same crucible according to the ratio of parts by weight and stir well, then add 7 parts of water part, stir the mixture evenly to make it have certain humidity and strength. Probe raw material required for each probe according to the actual mold volume;

[0024] b. Put the weighed raw material of the probe into the mold and compact it;

[0025] c. Take out the probe, after drying at room temperature, completely immerse the probe head in phosphoric acid for 3 to 4 minutes:

[0026] d. After the pickling probe is completely dry, it can be fired at high temperature.

Embodiment 2

[0028] In the method for manufacturing a probe for a rapid detector of hydrogen content in an aluminum alloy melt described in Example 1, the high-temperature firing process described in step d is as follows: heating the probe in the furnace from room temperature to 300° C., and keeping the temperature for 30 minutes, Continue to heat up to 800°C, keep the temperature for another 30 minutes, and then cool down to 200°C with the furnace.

Embodiment 3

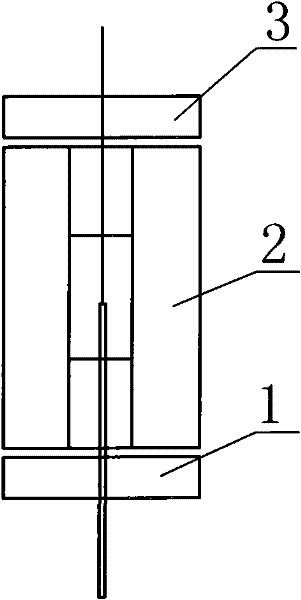

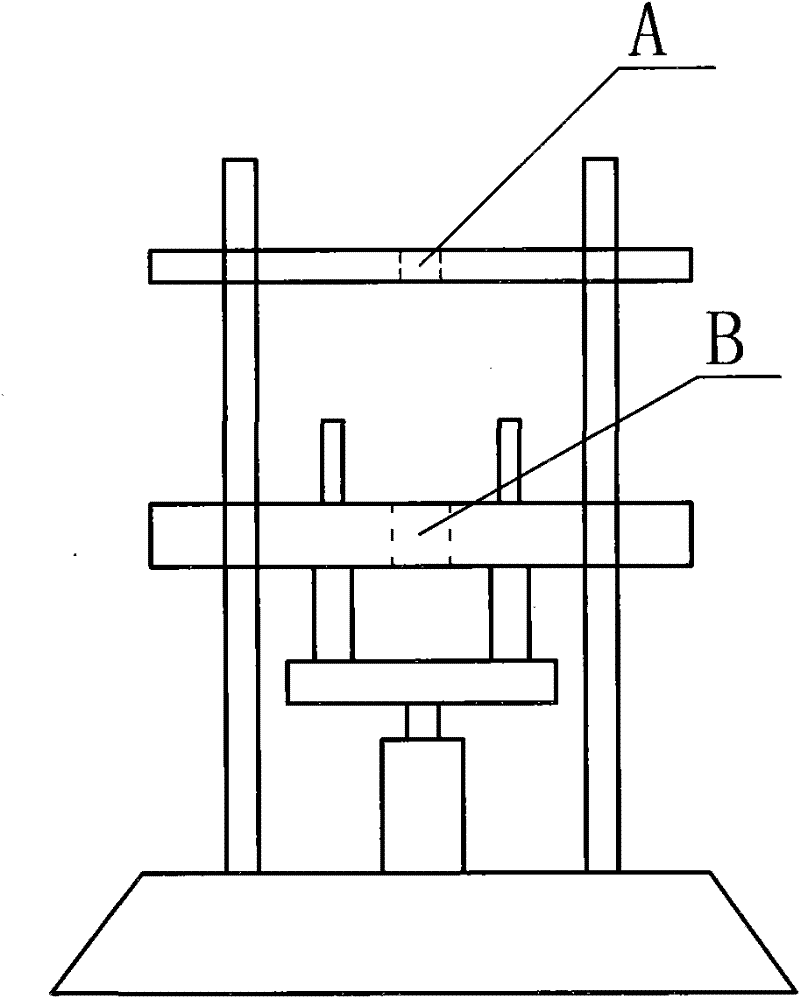

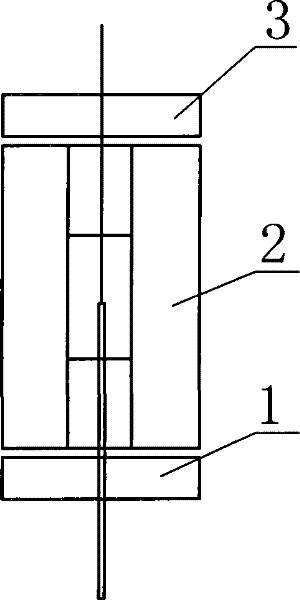

[0030] The mold structure used for pressing the probe is as follows: figure 1 shown. The pressing process of the probe is as follows: first, place the accessory 2 on the accessory 3, put the weighed material into the accessory 2 and make it firm. Press fitting 1 together with the metal conduit from the top of fitting 2, and rotate while pressing. In order to prevent the material from being pressed into the inner hole of the catheter, it is necessary to pre-thread an iron wire in the tube. The length of the iron wire passing through the top of the metal tube is 5 to 6mm. After the pressing action is completed, the iron wire is taken out. The mechanism for pressing the probe is as figure 2 As shown, the upper extrusion surface is rigidly connected with the frame, and the lower extrusion surface can move up and down in the vertical direction through the slide rail of the frame, and then the pressure is applied by the jack to squeeze the mold located between the two extrusion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com