Plasma processing apparatus and plasma processing method

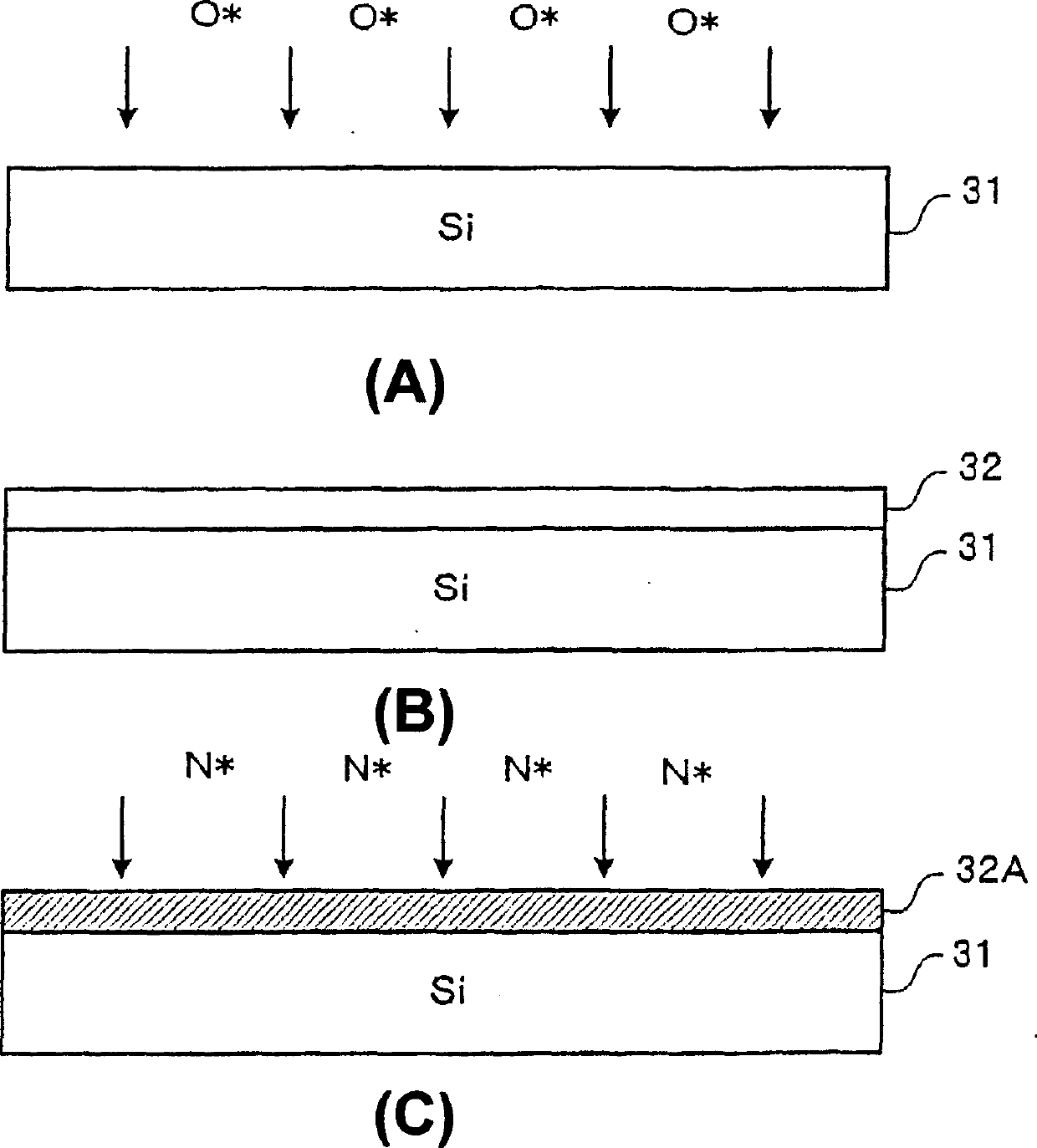

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of substrate degradation, transistor characteristic degradation, leakage current increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

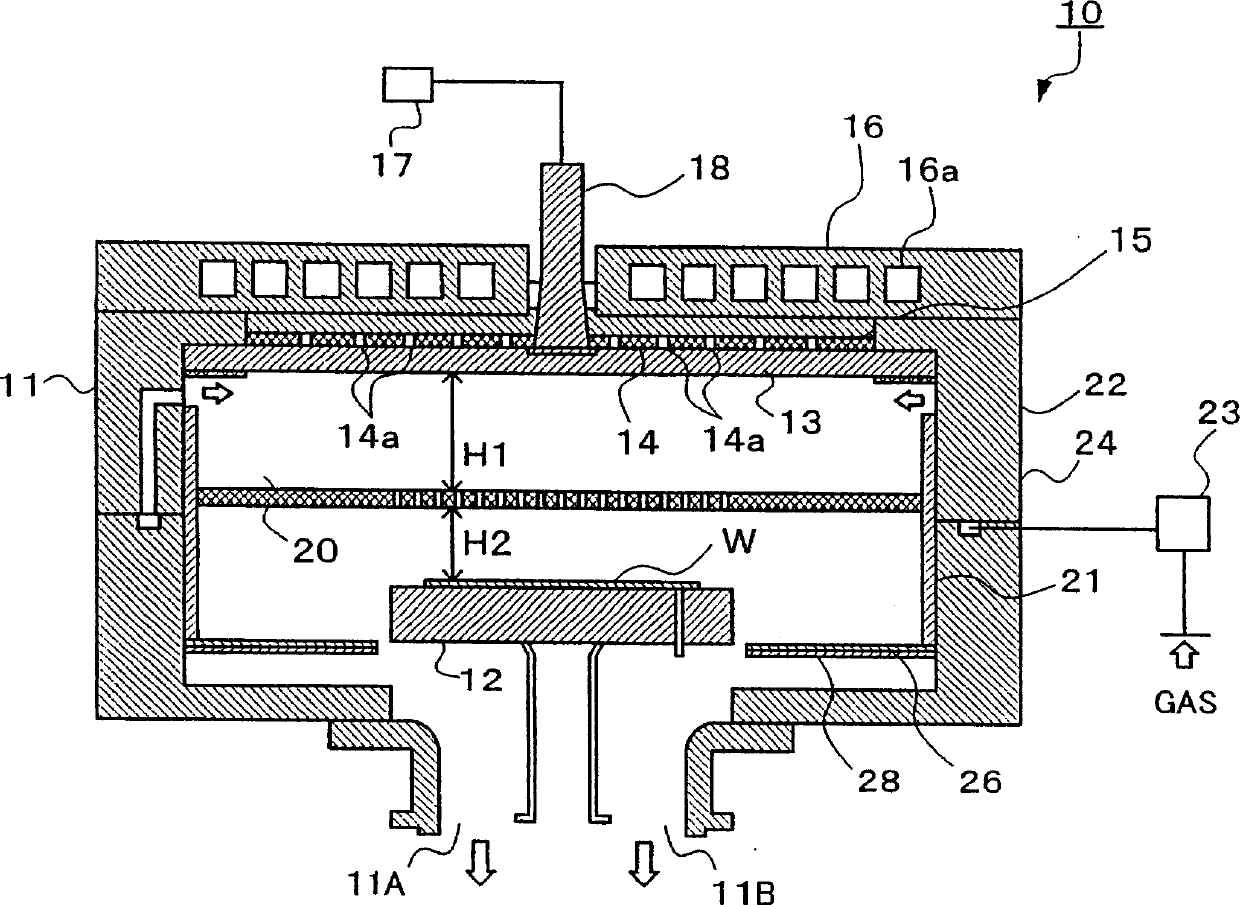

[0021] FIG. 1 shows a schematic configuration of a plasma processing apparatus 10 according to an embodiment of the present invention. The plasma processing apparatus 10 has a processing container 11 formed with a substrate holding table 12 holding a silicon wafer W as a substrate to be processed, and air (gas) in the processing container 11 is exhausted through exhaust holes 11A, 11B. In addition, the substrate holding table 12 has a heater function for heating the silicon wafer W. As shown in FIG.

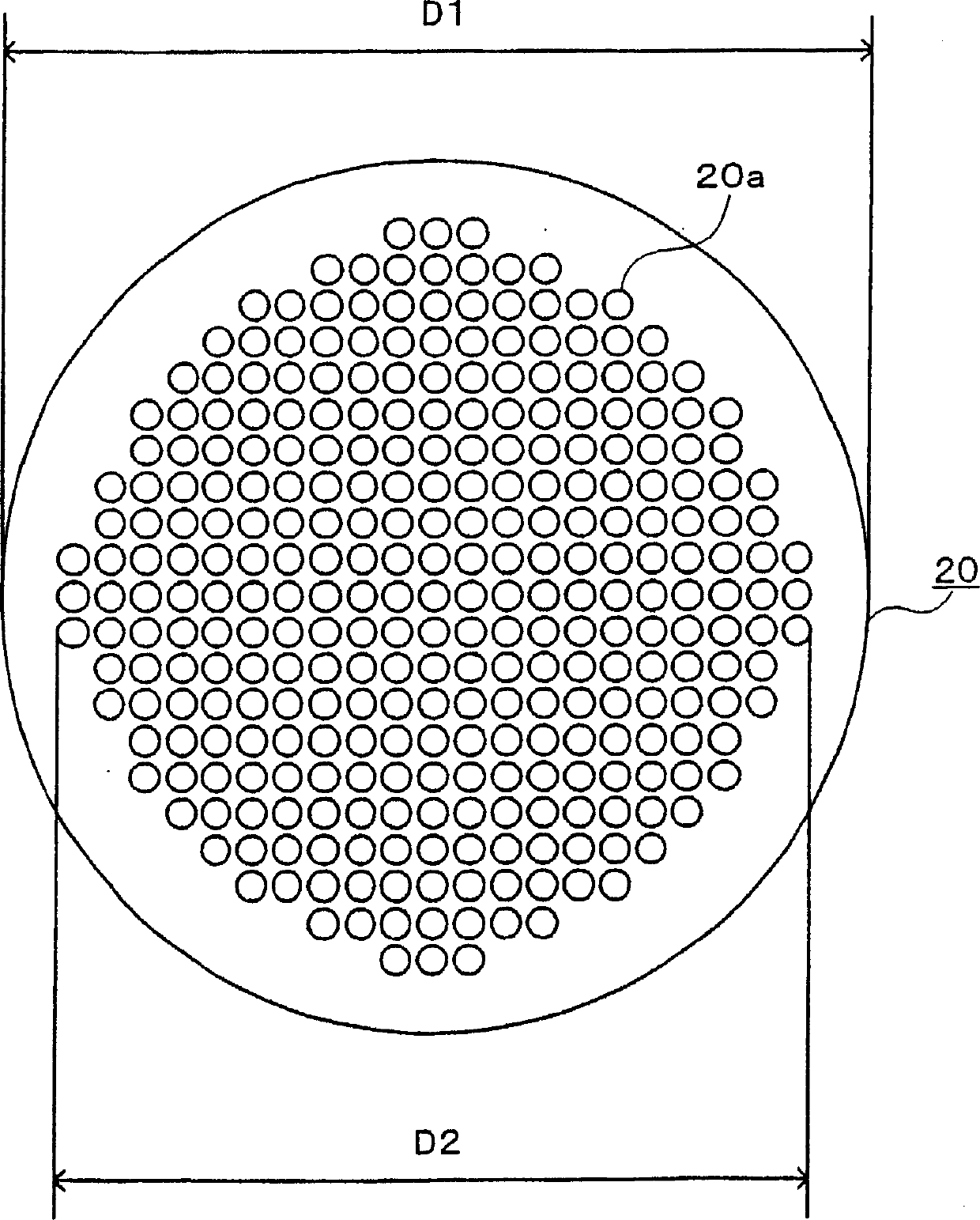

[0022] An opening corresponding to the silicon wafer W on the substrate holding table 12 is formed above the processing container 11 . The opening is made of quartz and Al 2 o 3 The formed dielectric plate 13 is plugged. A slot plate 14 functioning as an antenna is disposed on (outside) the dielectric plate 13 . The slot plate 14 is made of a conductive material such as a thin circular plate of copper, and a plurality of long holes 14a are formed. These elongated holes 14a a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com