Material changing method for switching from high transmission glass production to low transmission glass production

A technology with high transmittance and low transmittance, which is applied in the feeding of melting furnaces, glass furnace equipment, glass manufacturing equipment, etc., and can solve problems such as long refueling time, unclear refueling mechanism, and difficult control of time nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

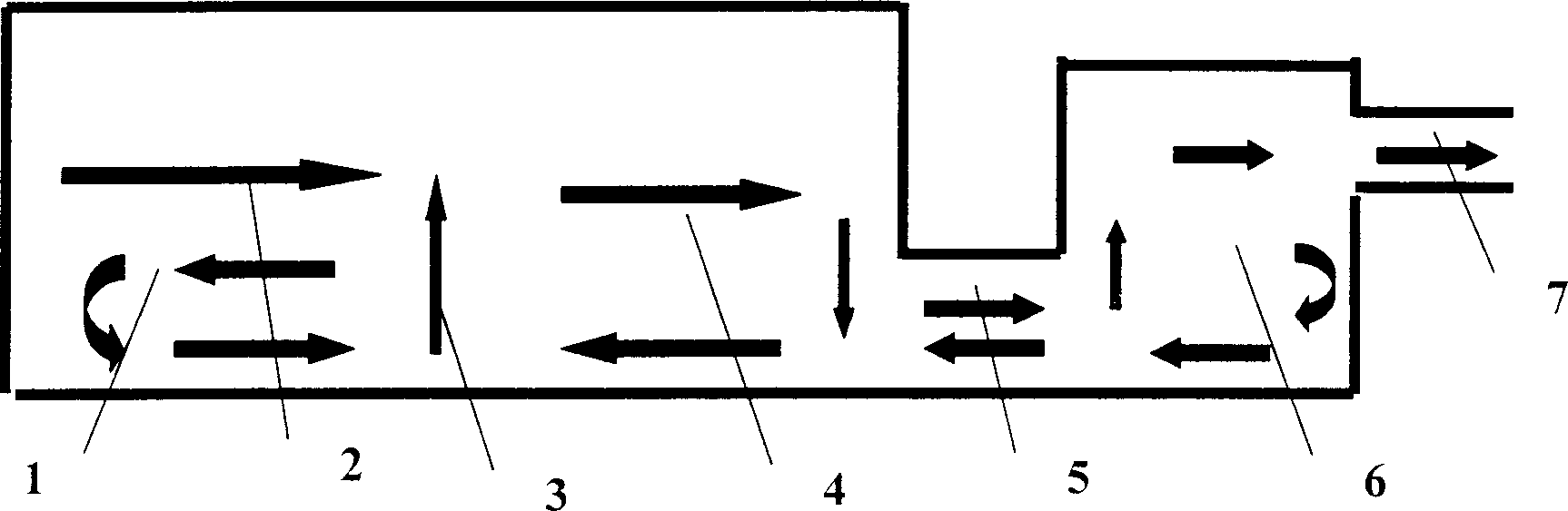

Method used

Image

Examples

Embodiment Construction

[0068] A 200-square-meter pool furnace switches from the production of high-transparency kinescope glass with a transmittance of 57% to the production of low-transmittance kinescope glass with a transmittance of 46%. The specific steps are as follows: Step 1: Determine the original high-transparency The composition of the picture tube glass colorant and the target low-transparency picture tube glass colorant is shown in Table 2 below.

[0069] Colorant ingredients

Fe 2 o 3

co 3 o 4

NiO

High-transparency picture tube glass (57%)

0.055%

0.00164%

0.0122%

Low-transparency picture tube glass (46%)

0.055%

0.00225%

0.0193%

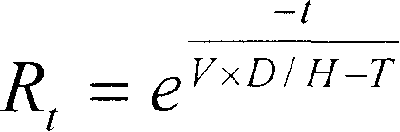

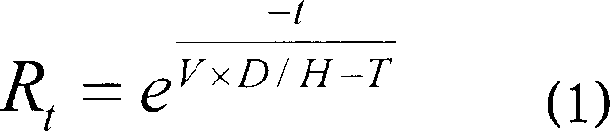

[0070] Step 2: Calculate the supplementary positive batch material formula.

[0071] The specific parameters of the pool furnace are as follows:

[0072] Pool furnace capacity V: 672 tons;

[0073] Daily output P (ton / day): 200 tons / day;

[0074] Hourly output H: H=P / 24=8.33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com