Process for producing high purity 1,2,4-trichlorobenzene and para-dichlorobenzene

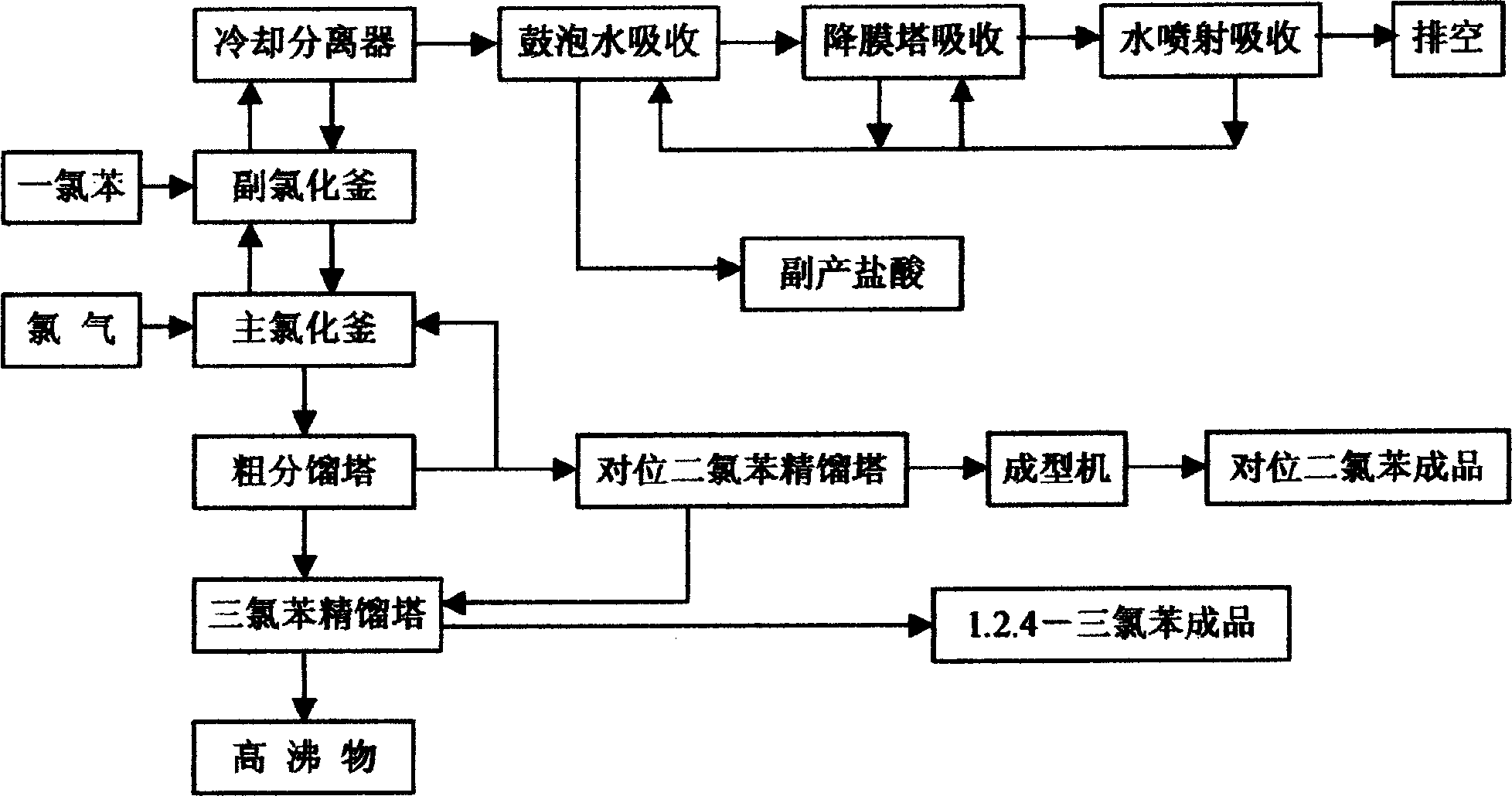

A production method and technology of trichlorobenzene are applied in the production of 2,4-trichlorobenzene and para-dichlorobenzene, in the field of high purity, and can solve problems such as process sewage, long production process flow, and unsuitability for industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0006] Put 1.8-2.3 tons of monochlorobenzene into the secondary chlorination kettle, add antimony trisulfide and ferric trichloride respectively, each accounting for 0.04-0.12% of the amount of monochlorobenzene, react with the chlorine gas from the main chlorination kettle, and the temperature is 50 ℃. When reacting at -80 degrees, hydrochloric acid gas is generated and the entrained monochlorobenzene is separated and recovered by the cooling separator. The hydrochloric acid gas is absorbed by bubbling water, and then absorbed by the falling film tower, and then absorbed by the water ejector, and then recycled to make 28 -30% concentration of by-product hydrochloric acid, inert gas evacuated. The above-mentioned monochlorobenzene etc. are put into the main chlorination still for 4-6 hours of reaction in the auxiliary chlorination still. The liquid chlorine is vaporized into gaseous chlorine, which is put into the main chlorination kettle with an hourly flow rate of 20-24 cubi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com