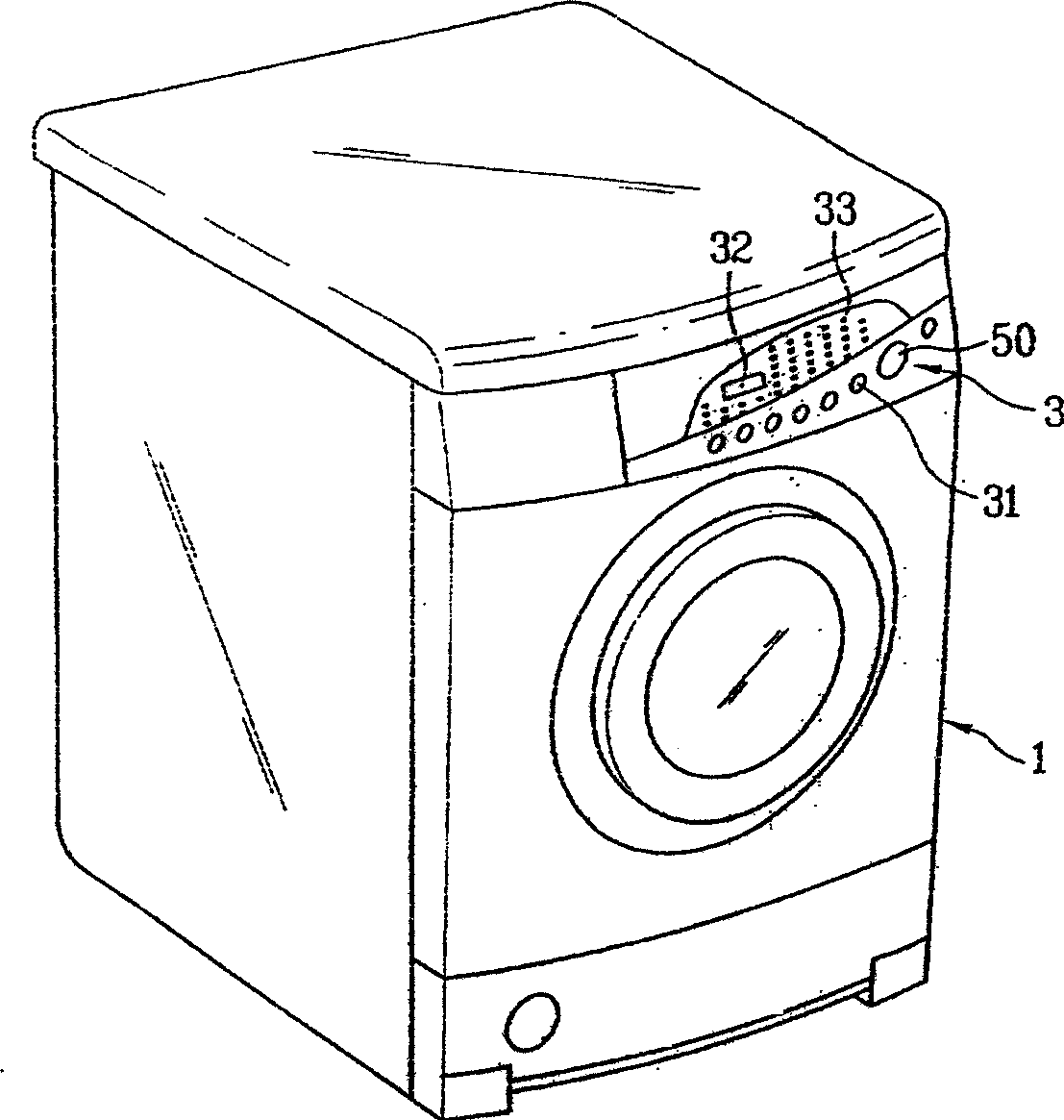

Knob mechanism structure of drum washing machine

A drum washing machine and knob technology, applied in the field of washing machines, can solve the problems of ineffective prevention of the damage of the rotary switch 5, reduced operation accuracy of the knob, and large loosening of the knob 50, so as to prevent damage, improve trust, and reduce the loosening of the left and right. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

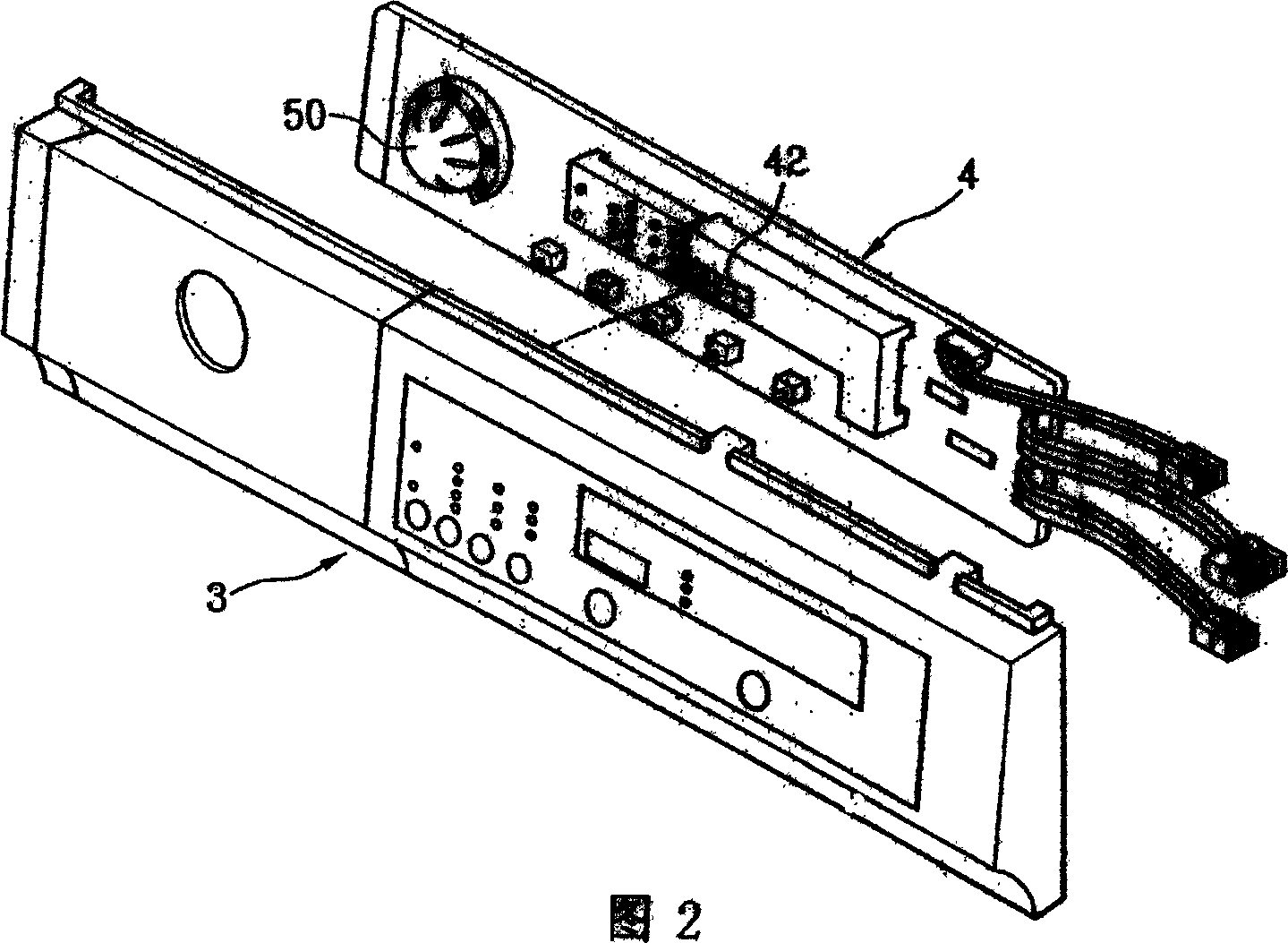

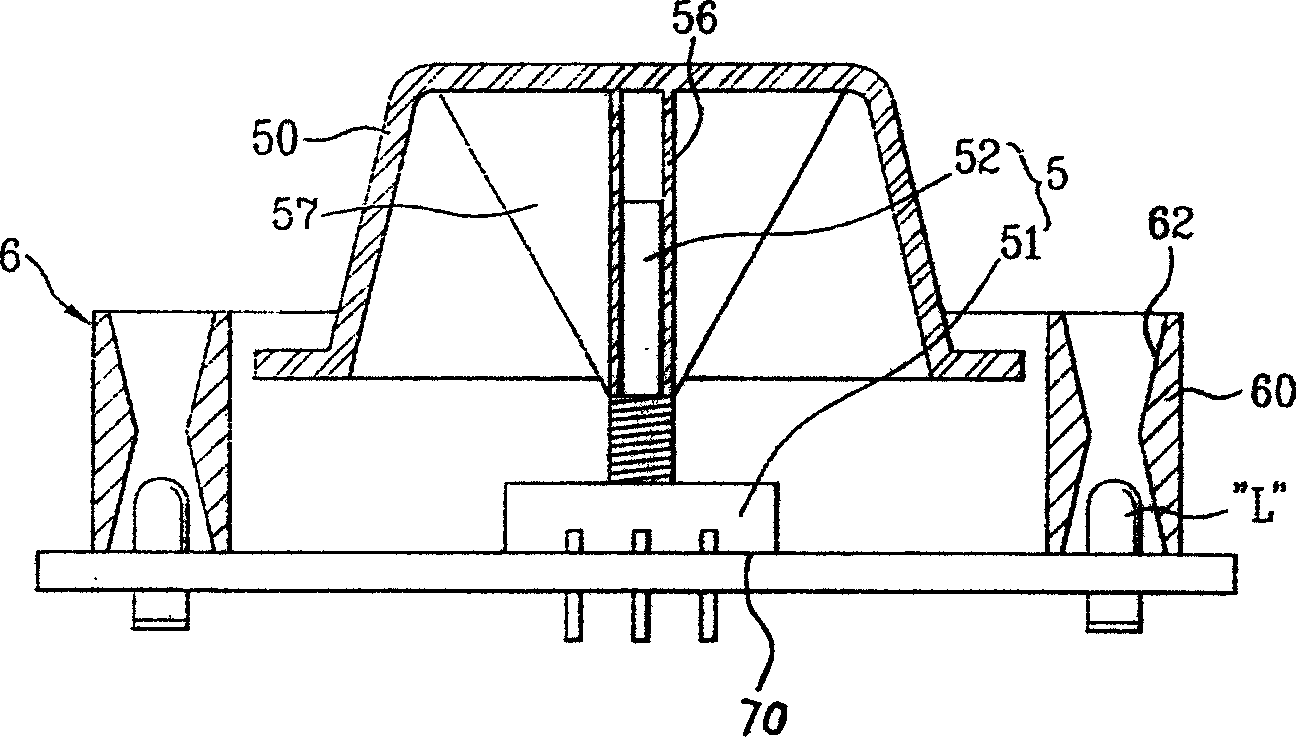

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: Figure 5 It is a sectional view of the knob mechanism of the present invention. Image 6 Yes Figure 5 The bottom view of the knob in .

[0046] As shown in the figure, the knob mechanism of the drum washing machine of the present invention is a rotary switch 5 composed of an encoder 51 fixed on the circuit board 70 and an encoder shaft 52 connected to the encoder 51; The insertion sleeve 56 of the encoder shaft 52 and the knob 50 constituted by the reinforcing ribs for strengthening the insertion sleeve 56 strength; the ring-shaped illuminator bracket 6 that surrounds the knob 50 and is fixed on the circuit board 70 is formed.

[0047] In the drum washing machine knob mechanism of the present invention composed of the above-mentioned components, the inner side of the main frame 60 of the illuminator bracket 6 is provided with a shaft supportin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap