Device for increasing the functional reliability of a hydraulic circuit of a hydraulically operable clutch

A hydraulic circuit and hydraulic operation technology, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of complex structure, easy-to-failure manufacturing, and high cost of pneumatic boosters, and achieve the goal of increasing operation and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

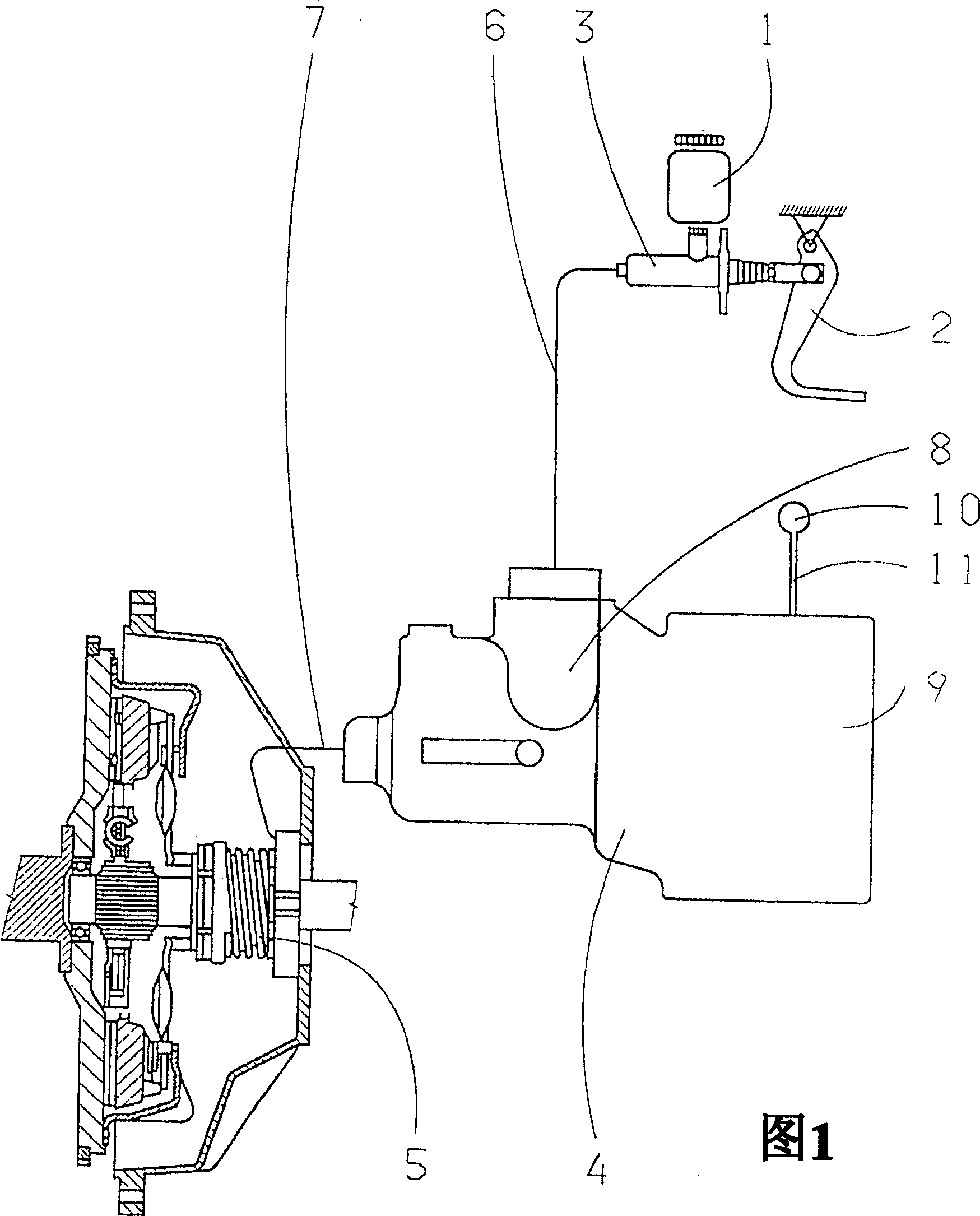

[0022] According to Figure 1, the hydraulic clutch control device with a pneumatic booster mainly includes: a transmitter cylinder 3 with a compensation container 1 and operated by a clutch pedal 2, a booster 4 behind the transmitter cylinder, and a clutch acting on the clutch release mechanism. The separating cylinder 5 and the hydraulic lines 6 and 7 , which create a fluid-tight connection between the transmitter cylinder 3 and the pressure booster 4 and between the pressure booster 4 and the separating cylinder 5 .

[0023] The booster 4 has a pneumatic zone 9 acting on the hydraulic zone 8 and the adjacent hydraulic lines 6 , 7 , which zone can be loaded with compressed gas in the activated state, supplied by an air compressor 10 via the pneumatic line 11 .

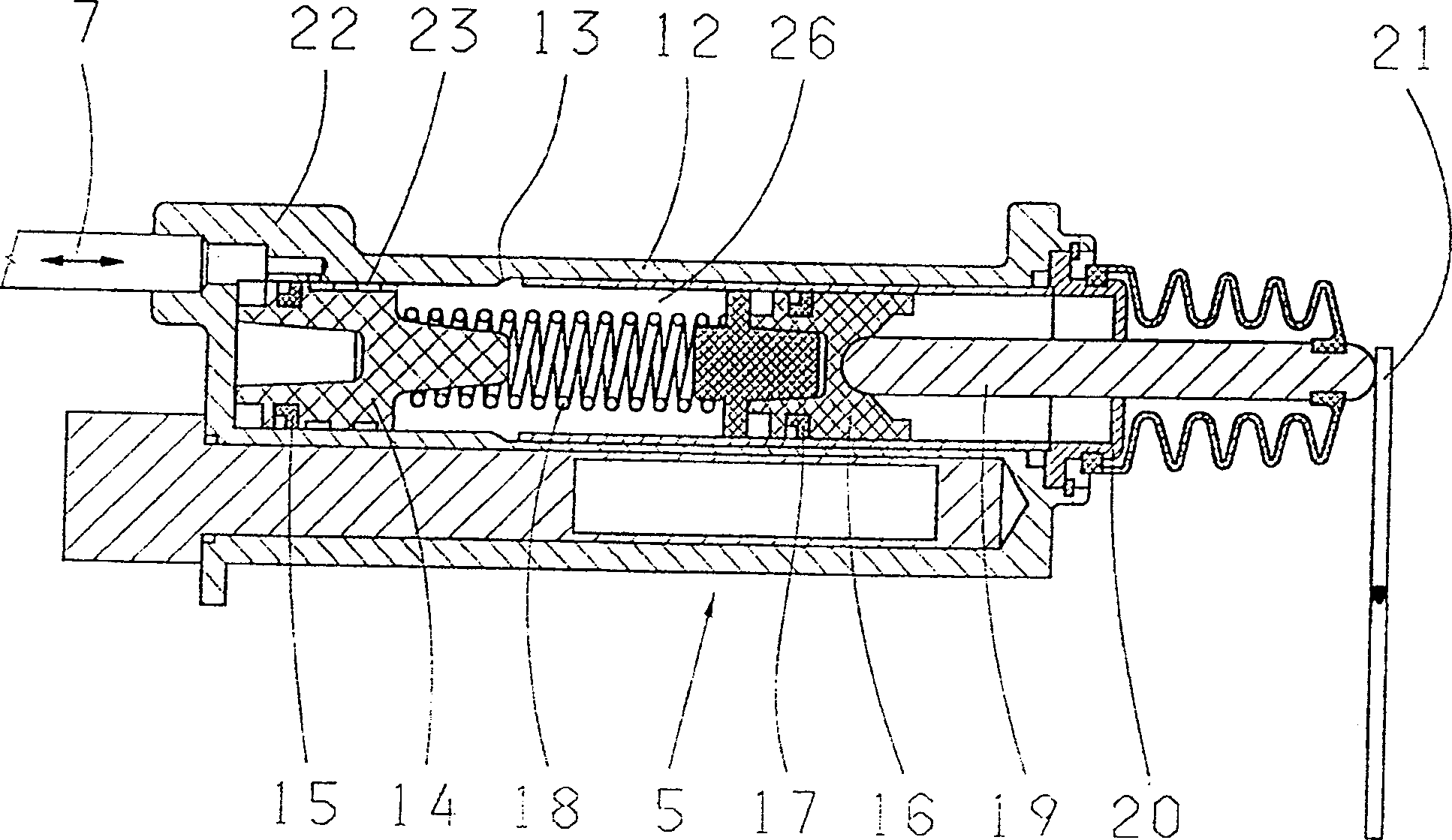

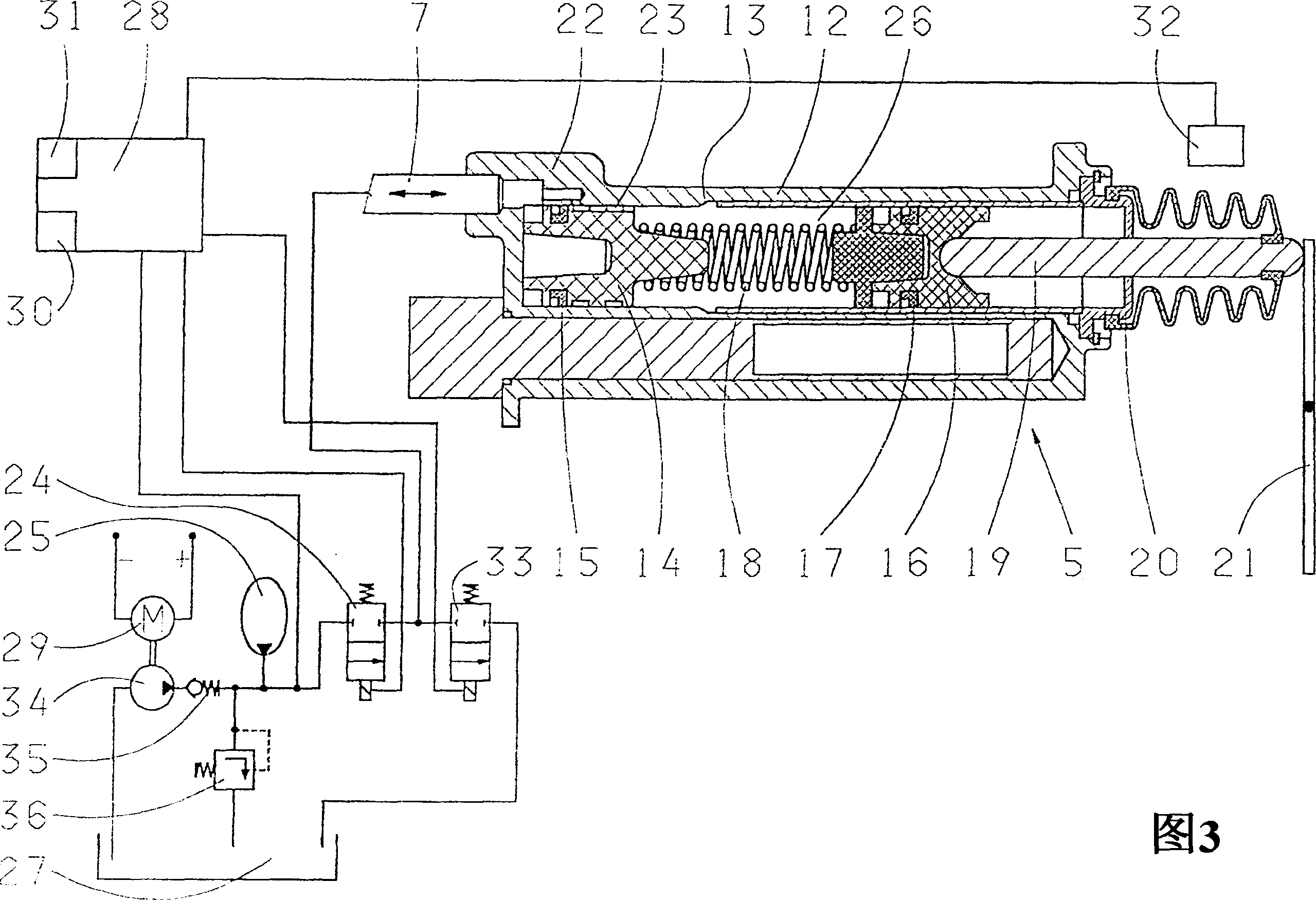

[0024] figure 2 The separating cylinder 5 is shown in the uncontrolled state. The substantially cylindrical housing 12 has a stepped bore 13 in which a primary piston 14 with a sealing ring 15 and a secondary piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com