Flocculation reactor

A reactor and flocculation technology, applied in the field of improvement of flocculation reactors, can solve the problems of uneven water flow speed, long flocculation reaction time, poor flocculation effect, etc., so as to improve the flocculation effect, shorten the flocculation reaction time, and avoid sludge accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

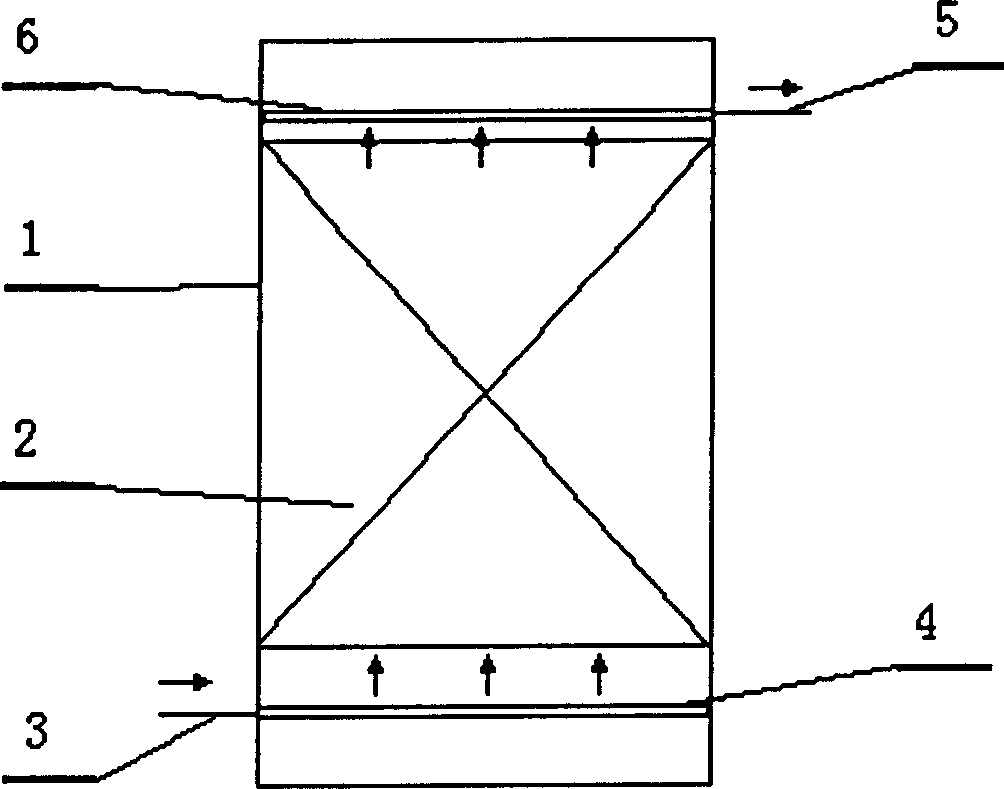

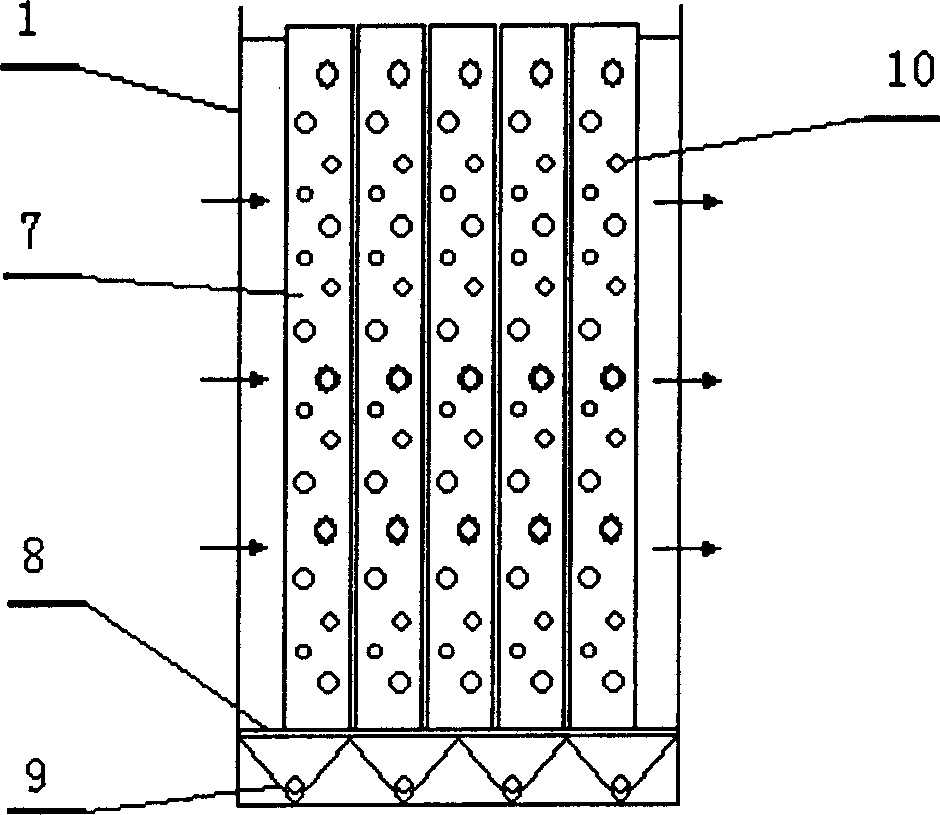

[0025] figure 1 The packing type flocculation reactor shown includes a shell 1, a flocculation reaction chamber inside the shell 1, an inlet pipe 3 and an outlet pipe 4 respectively arranged at opposite ends of the reaction chamber, and the reaction chamber is composed of filler 2.

[0026] The filler 2 is filled or installed in the housing 1, the water inlet distribution device 4 is connected with the water inlet pipe 3 at the lower part of the filler 2, and the outlet water distribution device 6 is connected with the water outlet pipe 5 at the upper part of the filler 2.

[0027] The shell can be made of various materials such as concrete, steel, plastic, glass fiber reinforced plastics or their combination, and the shape can be a cylinder, a cube, a cone, a sphere, etc. or their combination. Housings of different shapes and volumes can be combined in series or in parallel.

[0028] The filler is made of organic materials such as plastics, fiberglass, rubber, or inorganic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com